Synchronization conversion type consecutive step less variable speed mechanism

A stepless variable speed and transformable technology, applied in the direction of mechanical equipment, belts/chains/gears, transmission devices, etc., can solve problems such as poor power transmission, short service life, unfavorable use of automatic stepless variable speed locomotives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

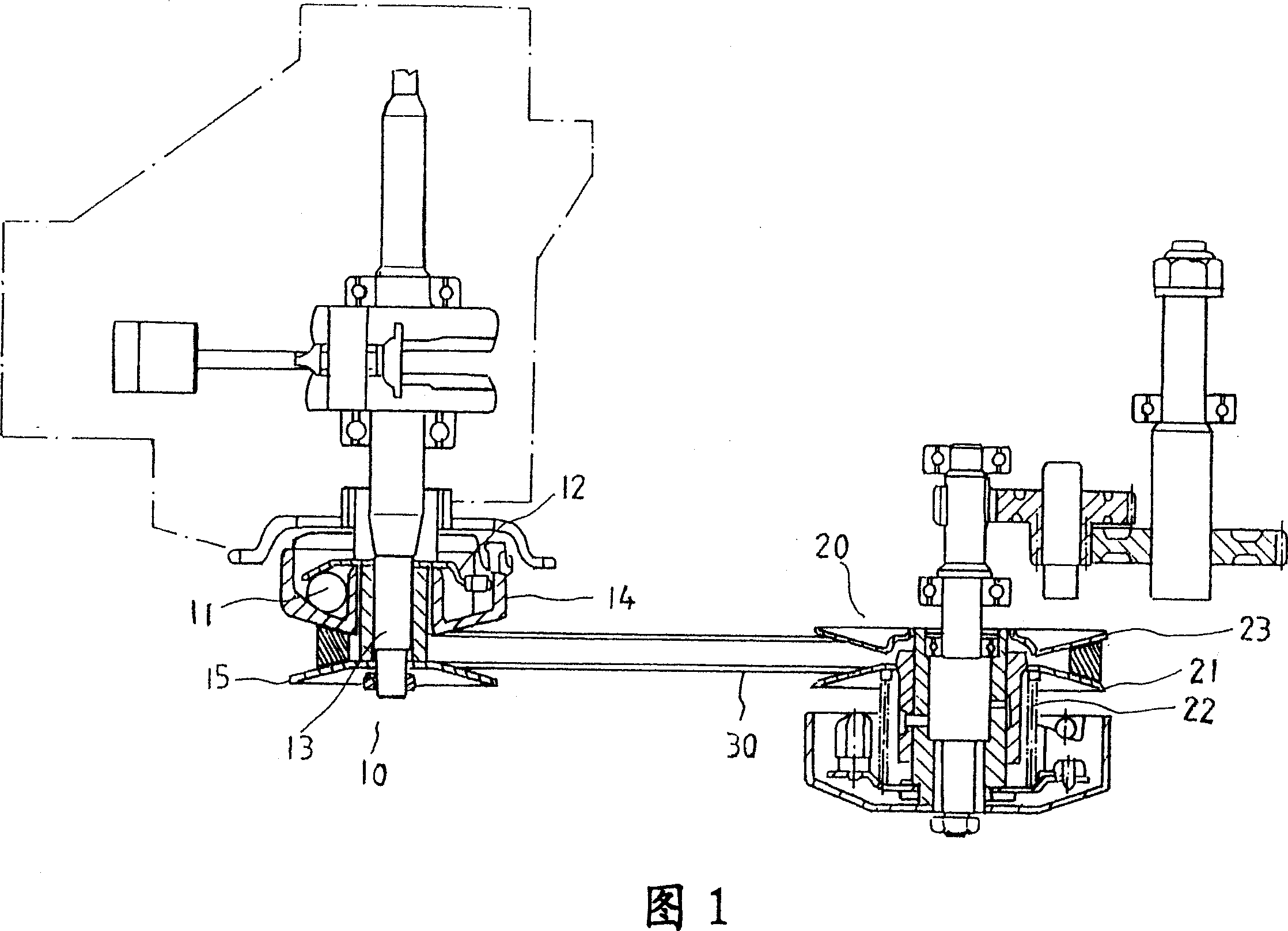

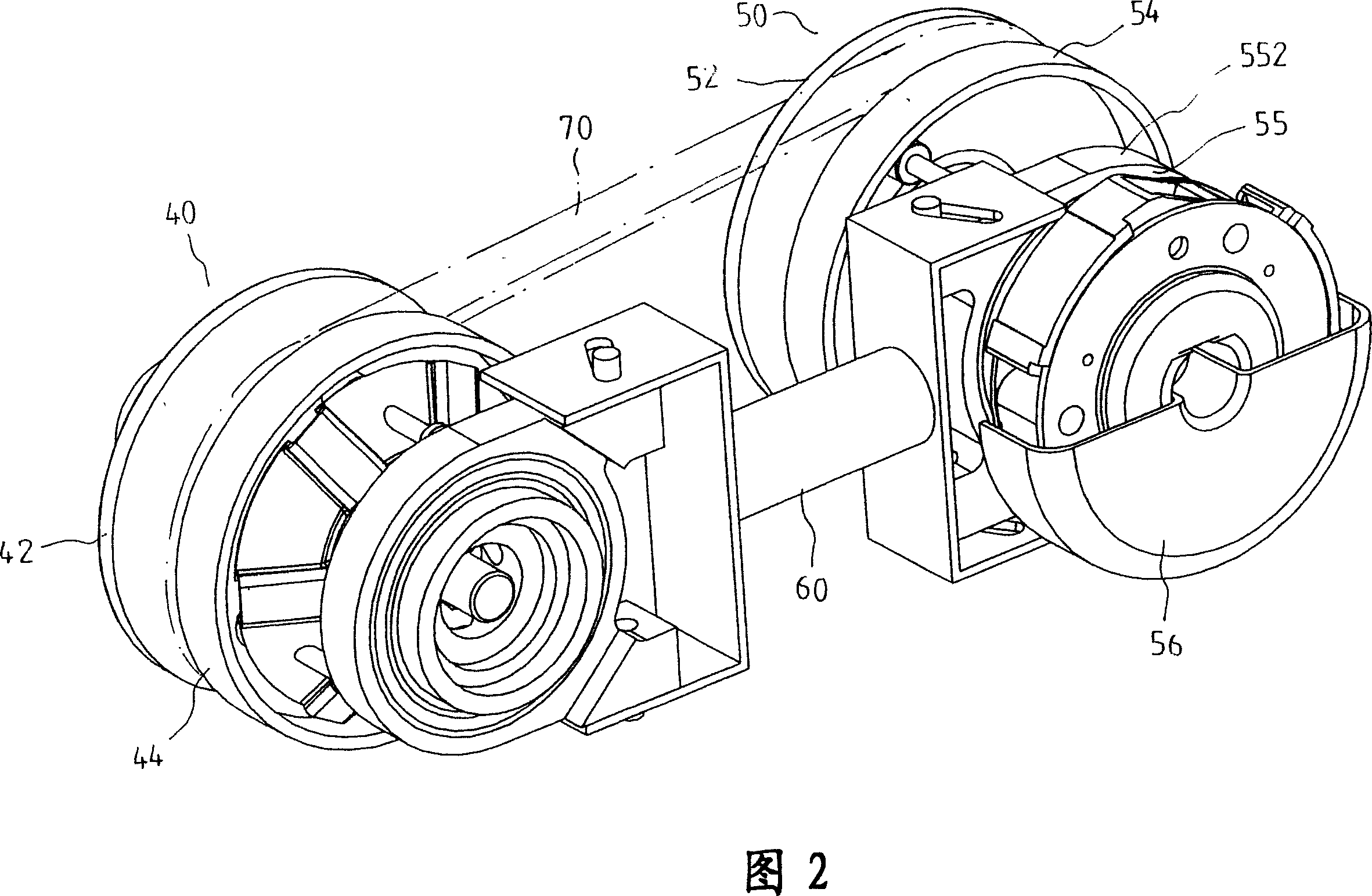

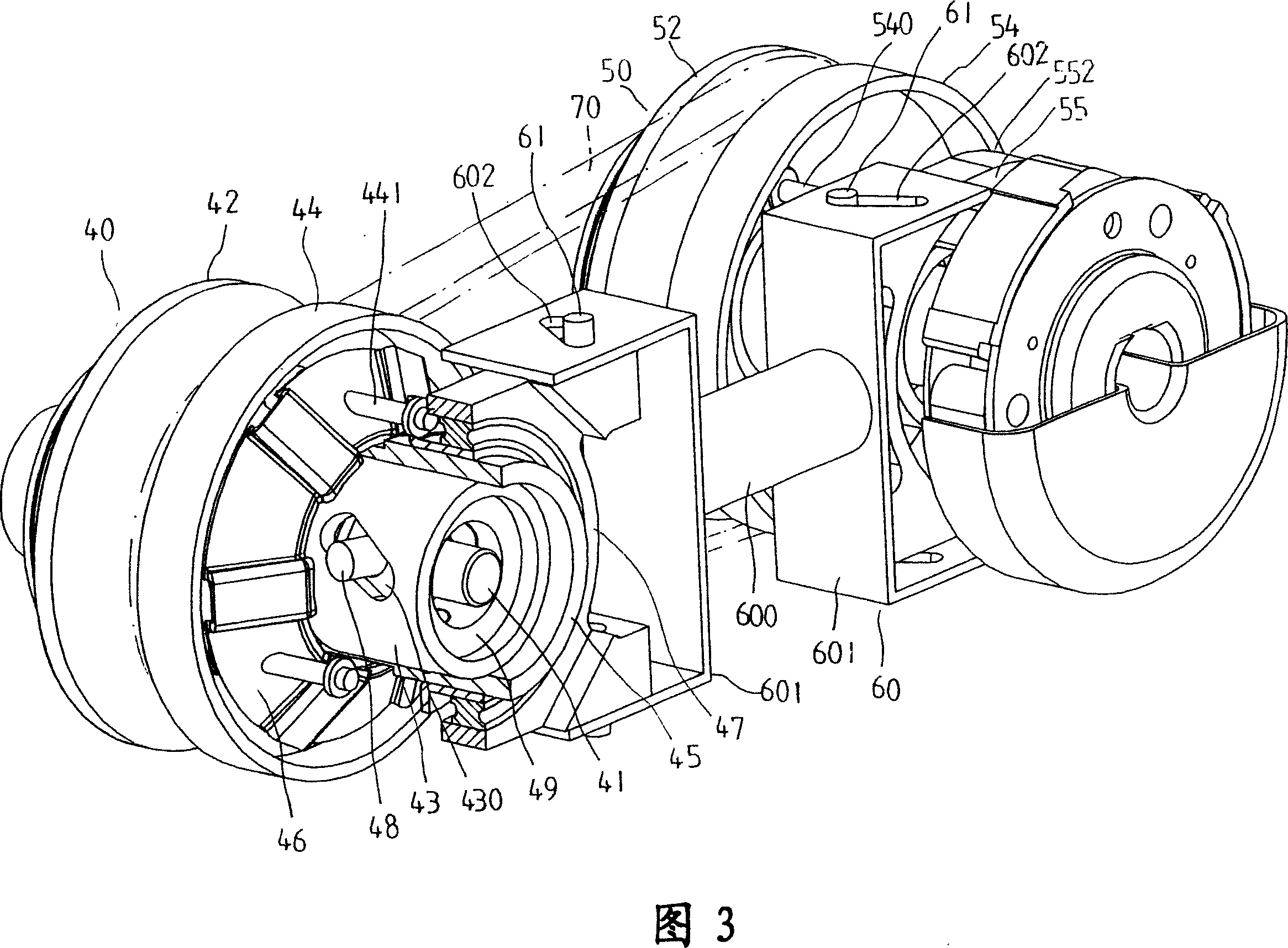

[0065] As shown in Figure 2, a synchronous conversion type continuous stepless transmission mechanism provided by the present invention is composed of a driving pulley set 40, a driven pulley set 50, a connecting frame 60 and a belt 70;

[0066] As shown in Figures 3 and 4, the driving pulley set 40 at least includes a first positioning pulley 42 defined on a drive shaft 41, and a first inner sliding sleeve 43 is nested therein. The first movable pulley 44 linked by the inner sliding sleeve 43 is sleeved with a back pressure plate 46 limited by a limiting sleeve 45, and a sliding seat 47 connected with the first movable pulley 44 is set. A plurality of Puli beads 440 are installed between the sharp plate 44 and the back pressure plate 46, and one end of the first inner sliding sleeve 43 is provided with more than one torsion groove 430, and each torsion groove 430 runs through a drive shaft respectively. The shaft 41 is combined with the interlocking toggle pin 48;

[0067] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com