Oscillatory flow tubular reactor with ripple wall

A tubular reactor and corrugated wall technology, applied in the field of reactors, can solve the problems of polymer molecular mechanical degradation, average molecular weight reduction, molecular weight distribution broadening, etc., and achieve the effect of not easy local accumulation, long-term operation, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

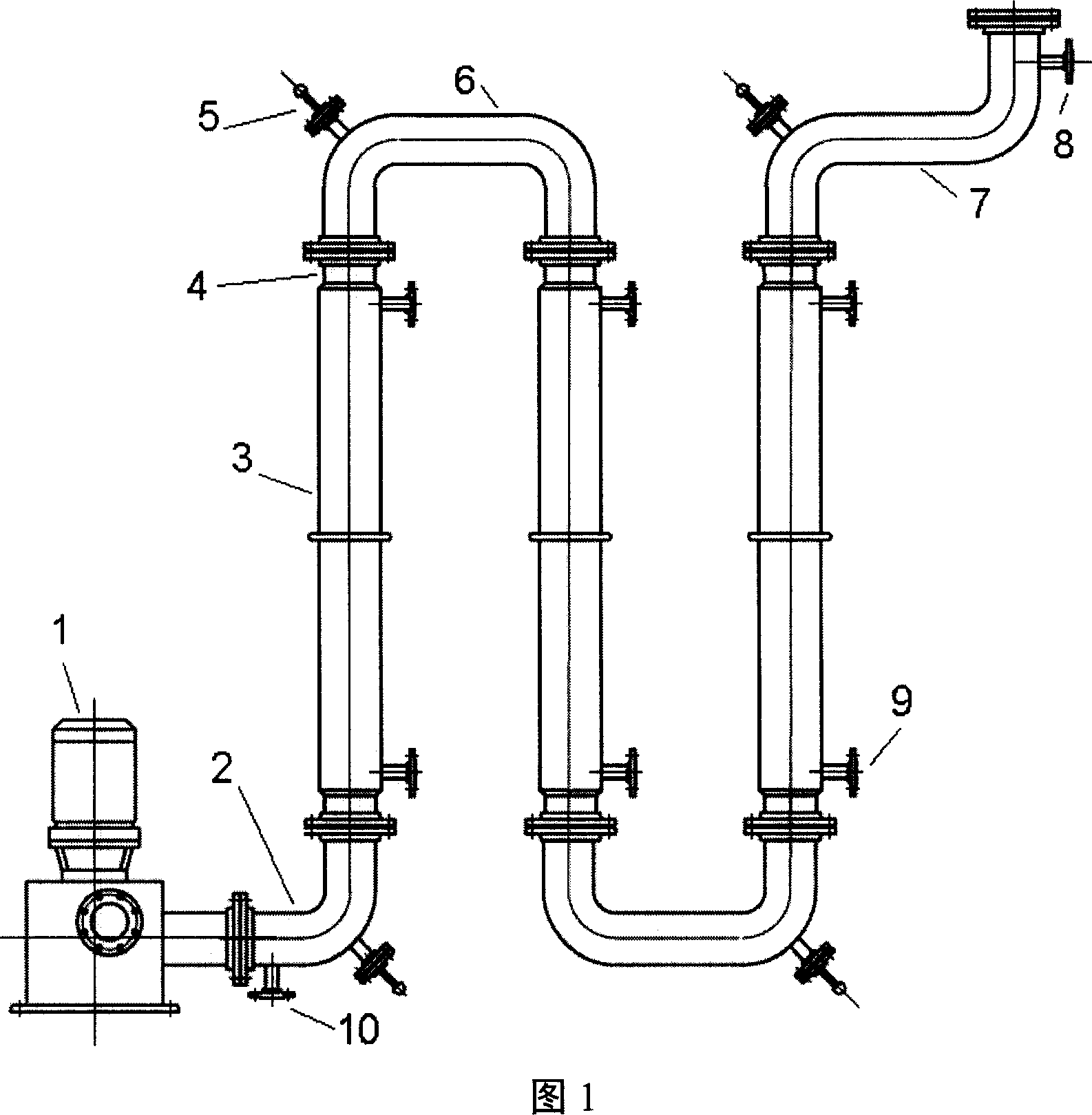

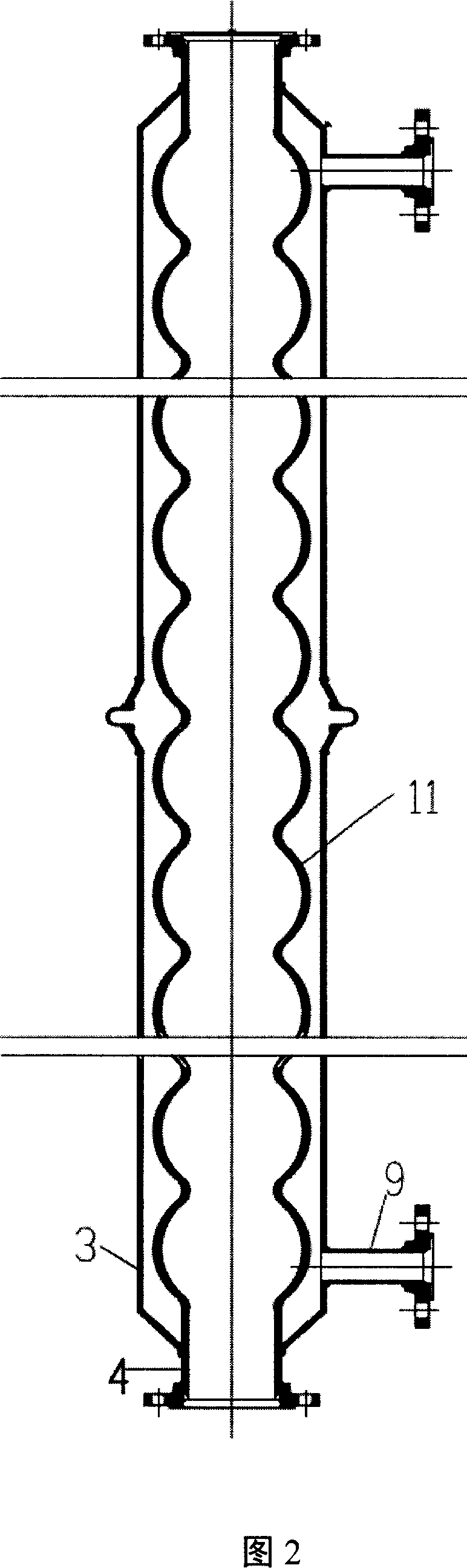

[0010] As shown in the figure, the corrugated wall oscillating flow tube reactor is composed of an oscillation generating mechanism 1, an inlet section 2, a reaction tube 4, and an outlet section 7 connected in sequence. The section 7 is provided with a discharge port 8, and the reaction tube 4 is composed of a vertically arranged corrugated wall tube, and the space inside the tube presents a multi-spherical chamber structure.

[0011] The ratio of the inner diameter of the spherical chamber to the inner diameter of the connecting channel between the chambers is 3-1.2:1. A heat exchange jacket 3 is arranged outside the reaction tube 4 . There are multiple reaction tubes 4 . A plurality of reaction tubes 4 are connected in series or in parallel

[0012] The inner diameter of the corrugated-wall pipe according to the present invention changes periodically along the central axis in an orderly manner, so that the inner space of the pipe presents a multi-spherical chamber structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com