Method and device for cleaning an electrode used in resistance point welding or a cap and device for resistance point welding

A technology of resistance spot welding and electrodes, which is applied in the direction of resistance welding equipment, electrode maintenance, electrode characteristics, etc., can solve the problems of small cleaning effect, and achieve the effect of shortening cleaning time and significant time benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

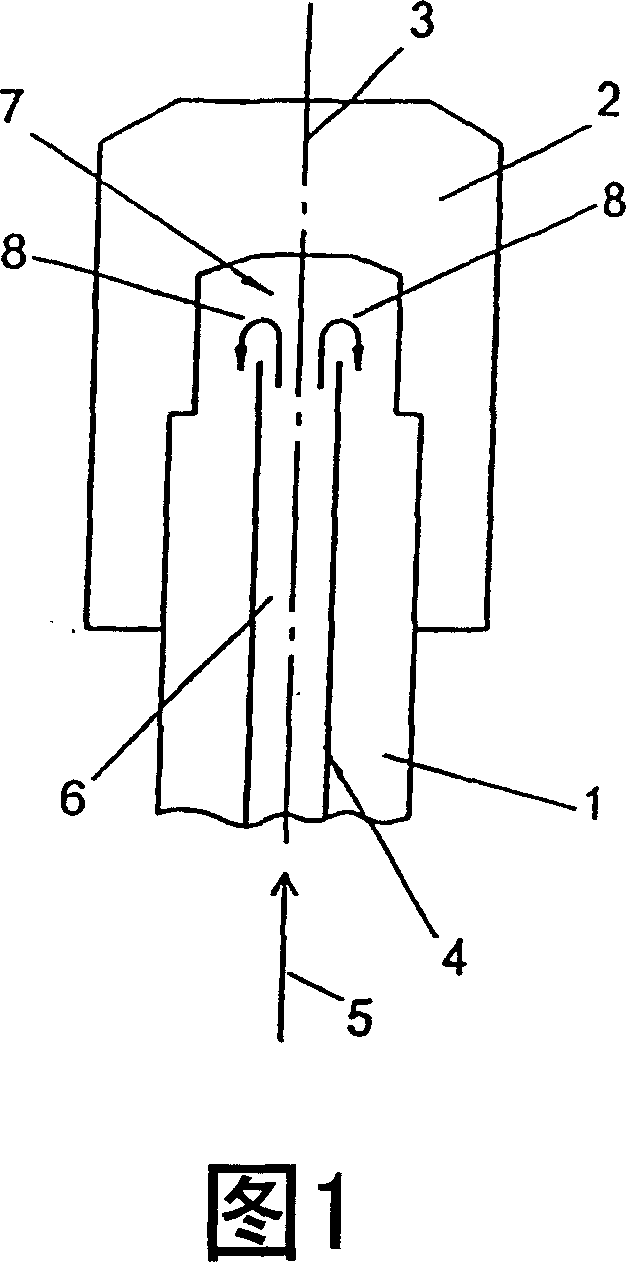

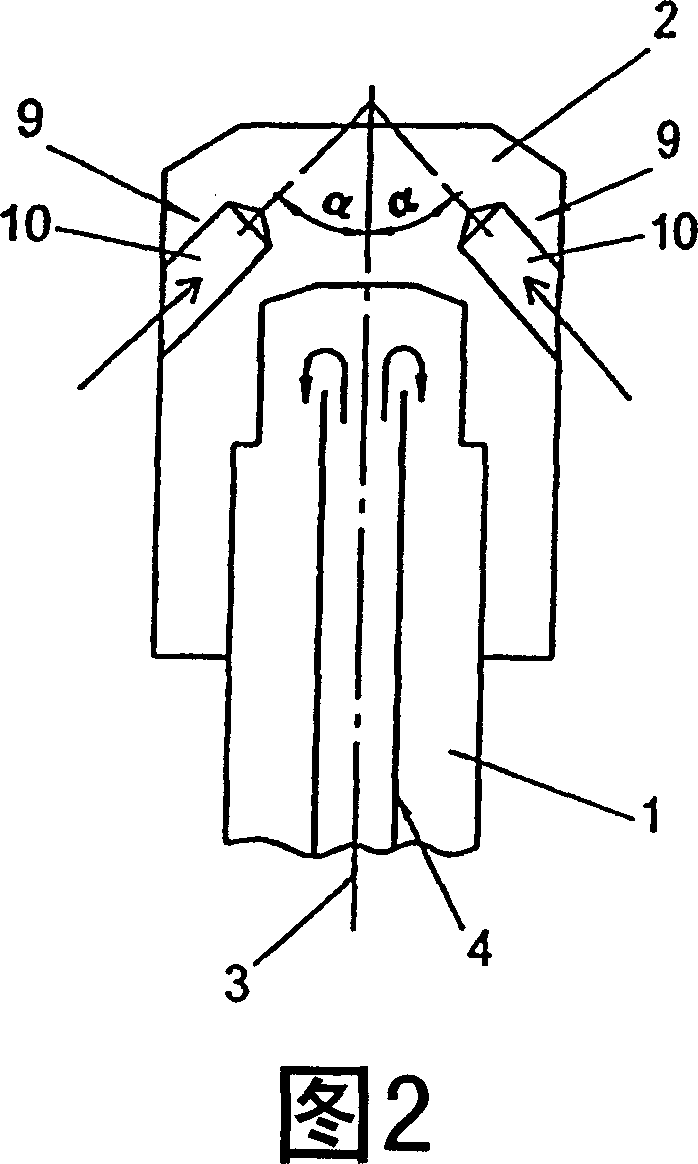

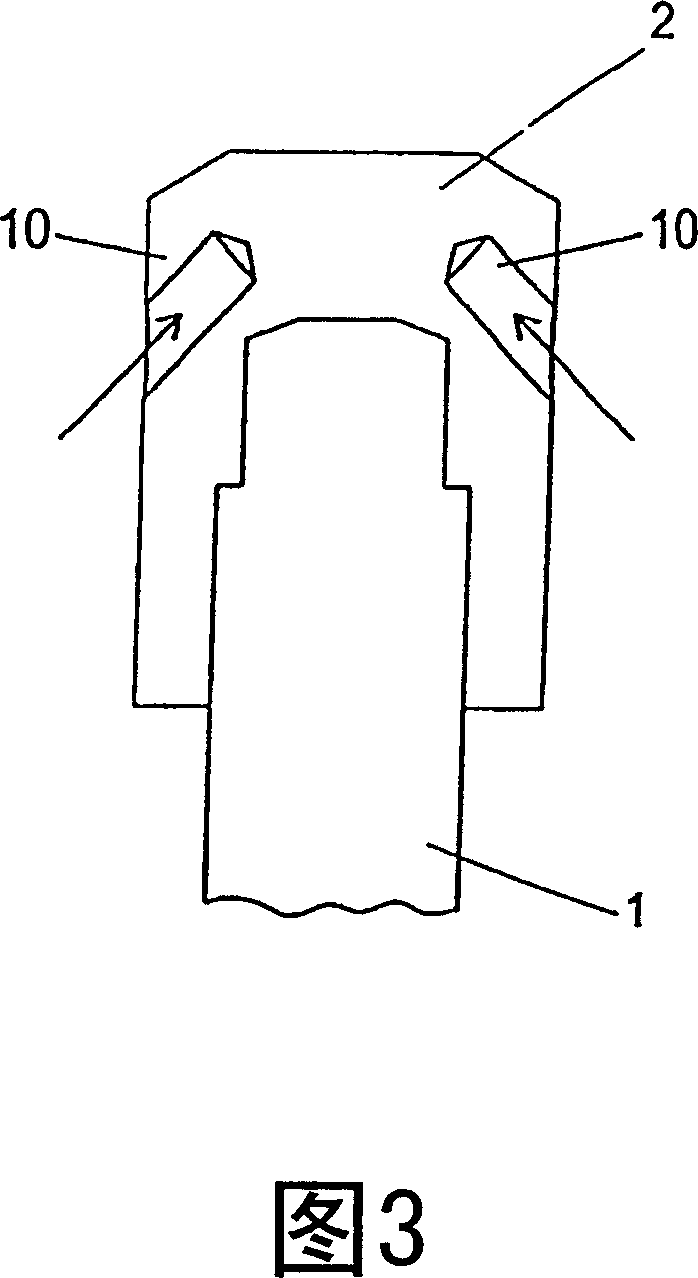

[0029] FIG. 1 shows the end of an electrode 1 for resistance spot welding which faces the workpiece to be welded during the welding process. Concentric to the longitudinal axis of the electrode 1 , a cover 2 is provided, which is pushed onto the end of the electrode 1 .

[0030]Electrode 1 has an inlet device 4 for feeding a coolant in the direction of arrow 5 . This coolant is used here to cool the electrode 1, in particular the electrode tip, during the welding process. Cooling water is usually used as coolant. The supply device introduces coolant via a cooling channel 6 into the end region 7 of the electrode 1 . There the coolant flushes around the end region 7 and deflects in the direction of the arrow 8 and flows back via return channels not shown, ie flows backwards from the electrode tip.

[0031] In this embodiment, the supply device is designed such that a cold medium can be supplied for cleaning welding spatter adhering to the electrodes. This is achieved in a ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com