Fire-retarded polycarbonate resin composition

A kind of composition and technology of flame retardant additive, applied in the field of flame retardant polycarbonate resin composition, can solve problems such as incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

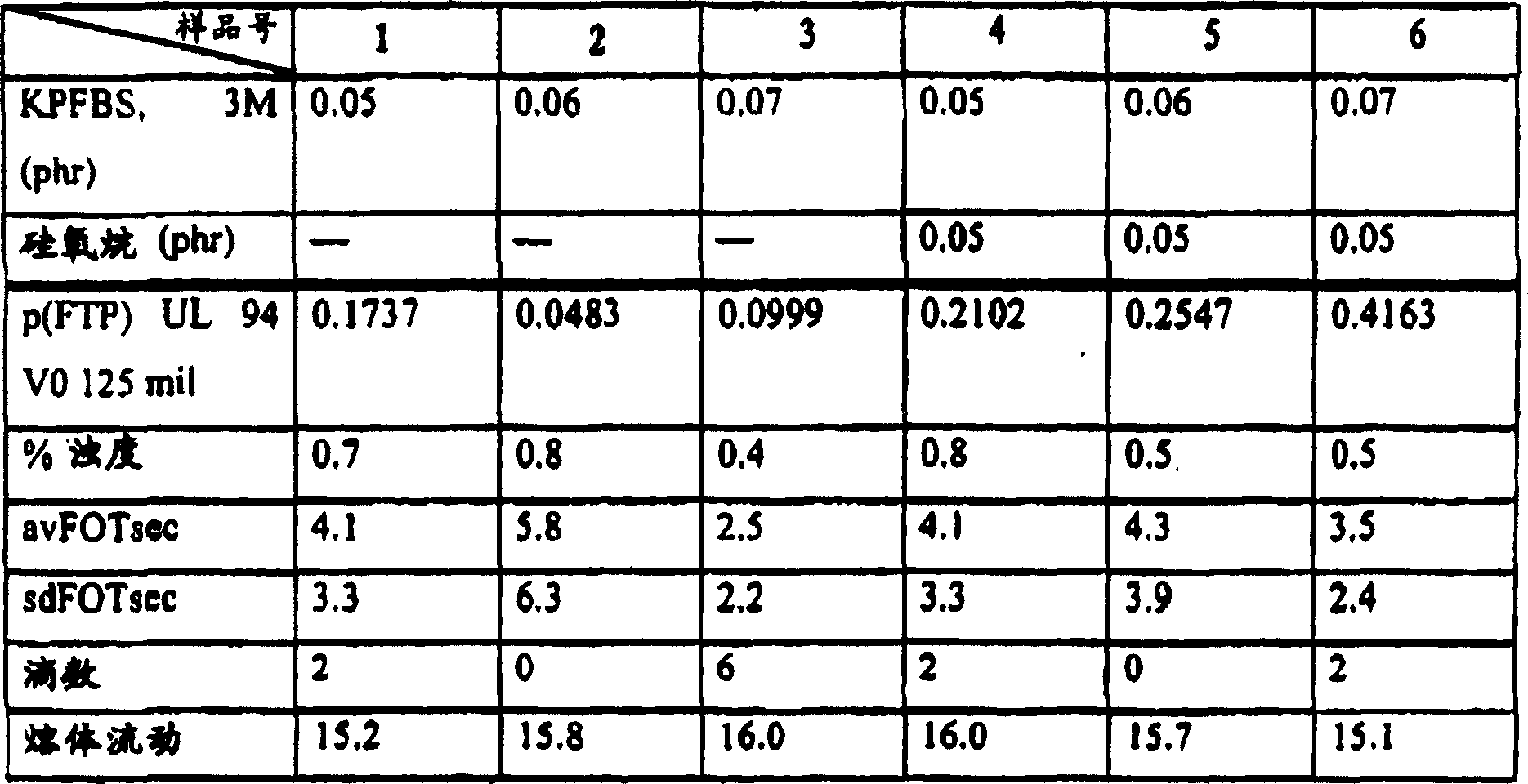

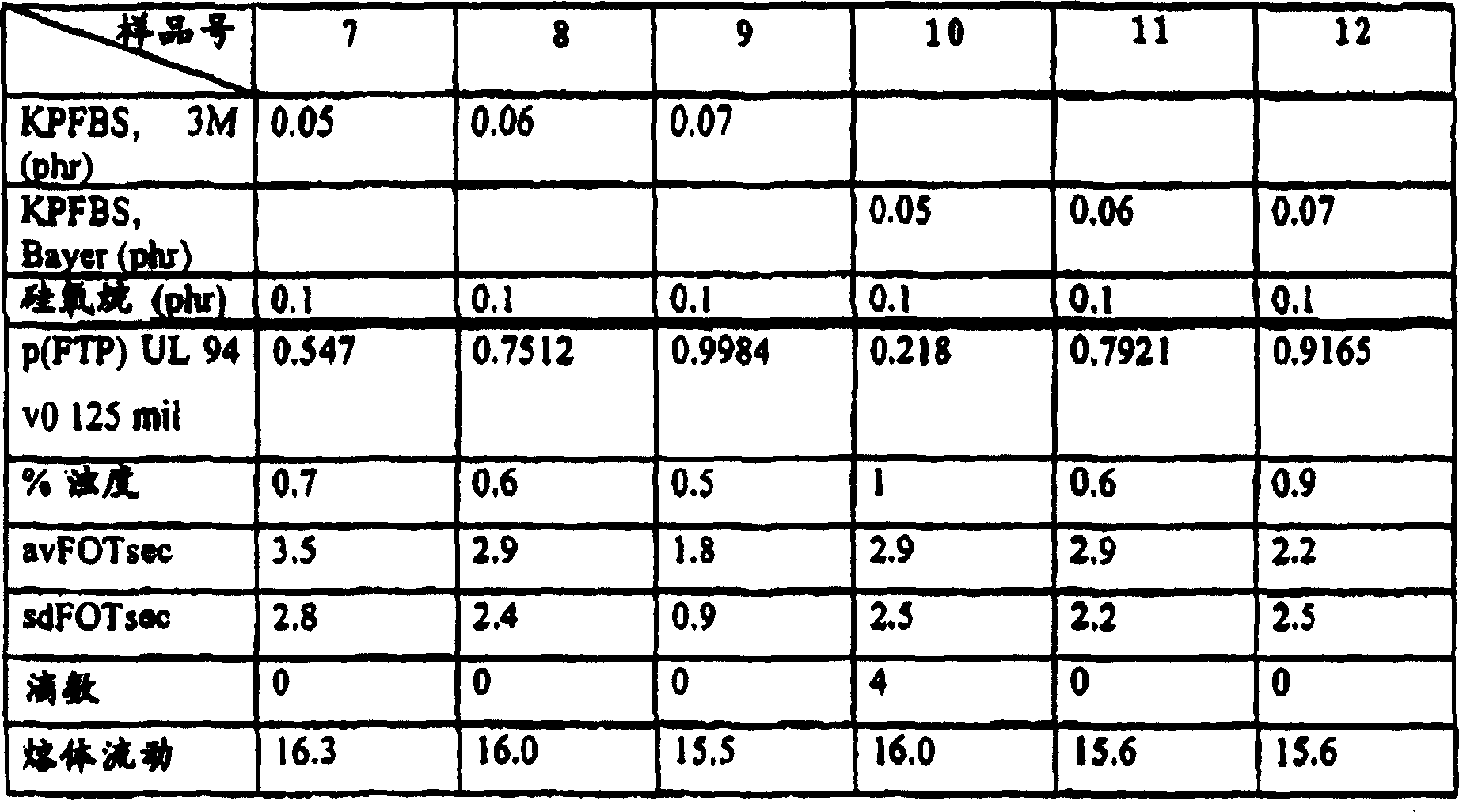

[0017] Polycarbonate samples for flammability testing according to the UL94 procedure were prepared by blending two different molecular weight grades of linear LEXAN(R) polycarbonate resin to achieve a target melt flow of 15 to 16, according to ASTM D1238 Measured at 300°C, 1.2 kg. Certain compositions also included 0.35 phr of pentaerythritol tetrastearate (PETS) mold release agent. The powder blend samples were extruded and cut into beads at a temperature range of 230 to 290°C. These bead samples were injection molded at a temperature of 295°C into test parts having dimensions of 5 inches by 1 / 2 inches and a thickness of 125 mils.

[0018] These parts were tested using the standard Underwriters Laboratory UL94 test method (2 day treatment method), except that 20 bars were tested instead of the usual 5 bars. The data was analyzed by first calculating the average time to fire (avFOTsec), standard deviation of time to fire (sdFOTsec) and total drops and using statistical meth...

Embodiment 2

[0031]Samples were prepared in the same manner as in Example 1, except that the polycarbonate resin used was 70 parts by weight of branched polycarbonate resin containing 0.42mol% 1,1,1-tris(hydroxyphenyl)ethane and A blend of 30 parts by weight linear polycarbonate resin to achieve a target melt flow of 2 to 3, measured according to ASTM D1238 at 300°C, 1.2 kg. Also included is a UV stabilizer (UV5411, 2-(2-hydroxy-5-tert-octylphenyl)benzotriazole). Samples were extruded at 240 to 305°C and injection molded at 320-332°C into test parts having thicknesses of 60 mil, 75 mil and 125 mil. These formulations and results are summarized in Tables 2A and B. A comparative test was carried out at 60mil and 125mil. The 60 mil test showed only marginal performance with no trend for all samples with KPFBS and drip failure for all samples without KPFBS. The 125 mil test had p(FTP) 0.9867 for the sample with 0.07K PFBS. Other samples containing KPFBS were not tested as they passed at 75...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com