Coil with a contact sleeve for electrical connection

A technology of electrical connection and coil, which is applied in the direction of conductive connection, permanent deformation, connection and coil, etc. It can solve the problems of high cost and complexity of winding wire connection, achieve reliable positioning and avoid manufacturing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention will now be described in detail with reference to the accompanying drawings.

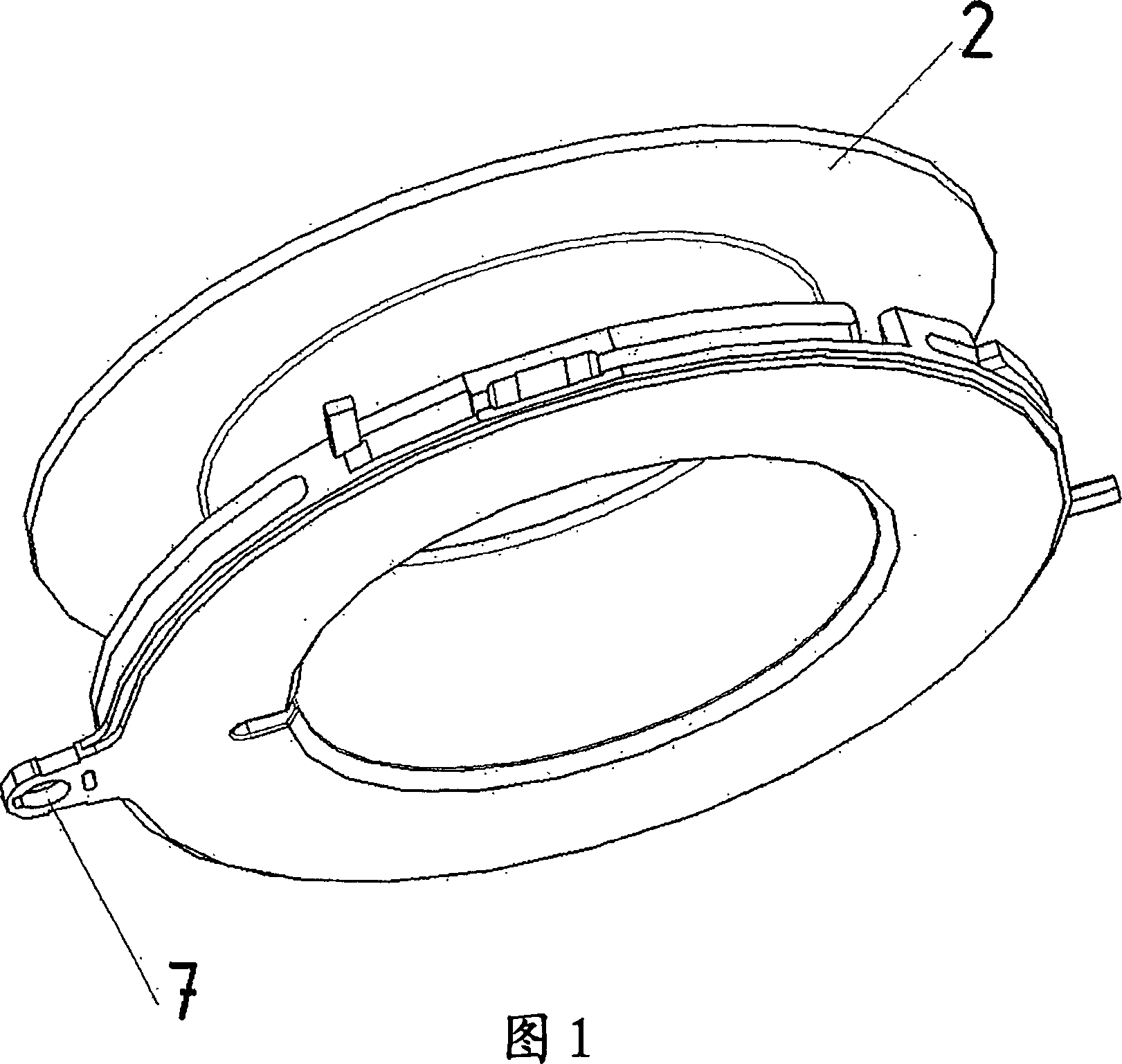

[0033] FIG. 1 shows a coil carrier 2 . The coil carrier can advantageously be produced as a plastic injection-molded part and has a holder 7 as fastening for the outgoing cable.

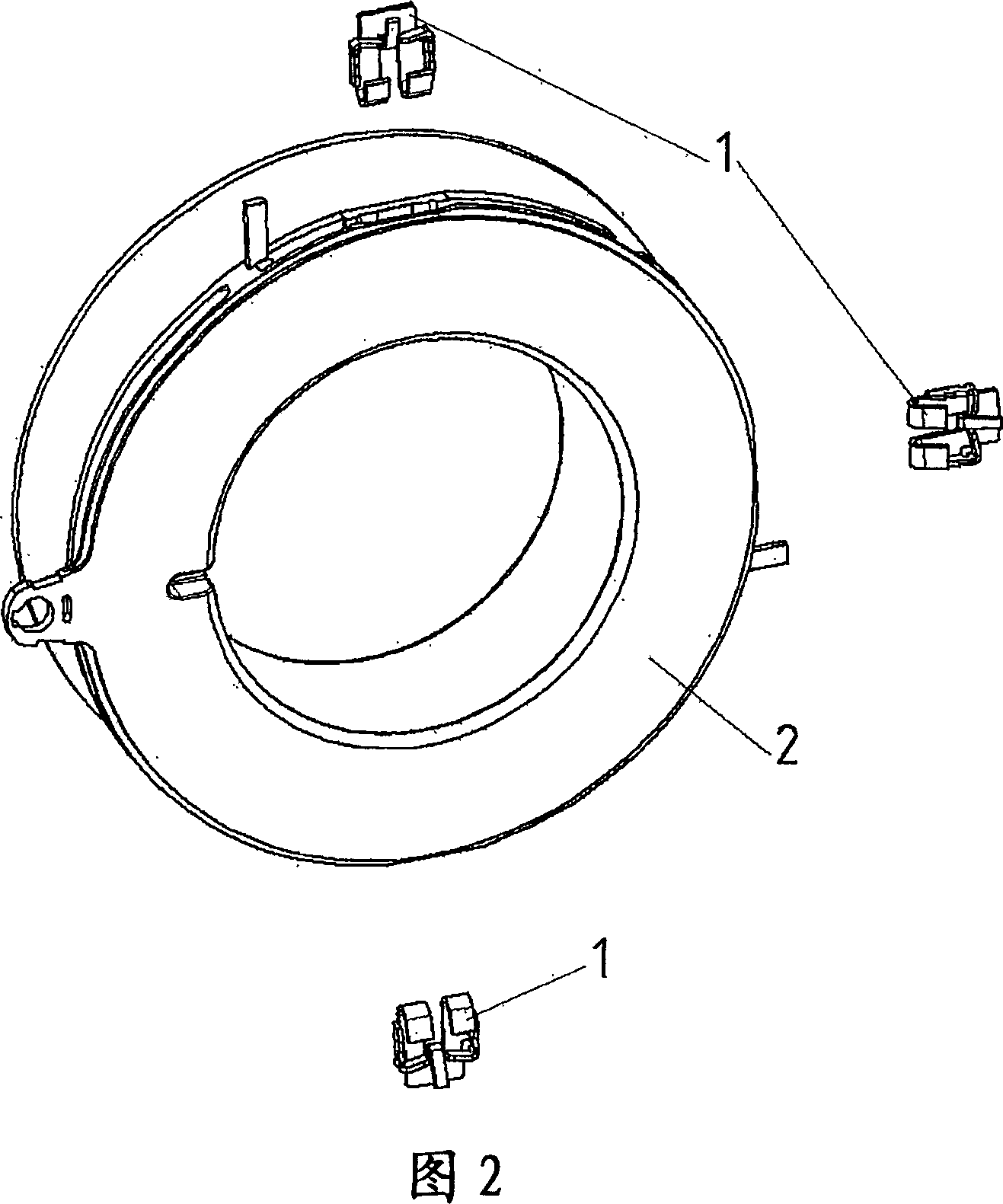

[0034] FIG. 2 shows three sleeves 1 which can be inserted into the coil carrier at three points on the outer circumference.

[0035] 12 and 13 show the detailed structure of the sleeve 1 .

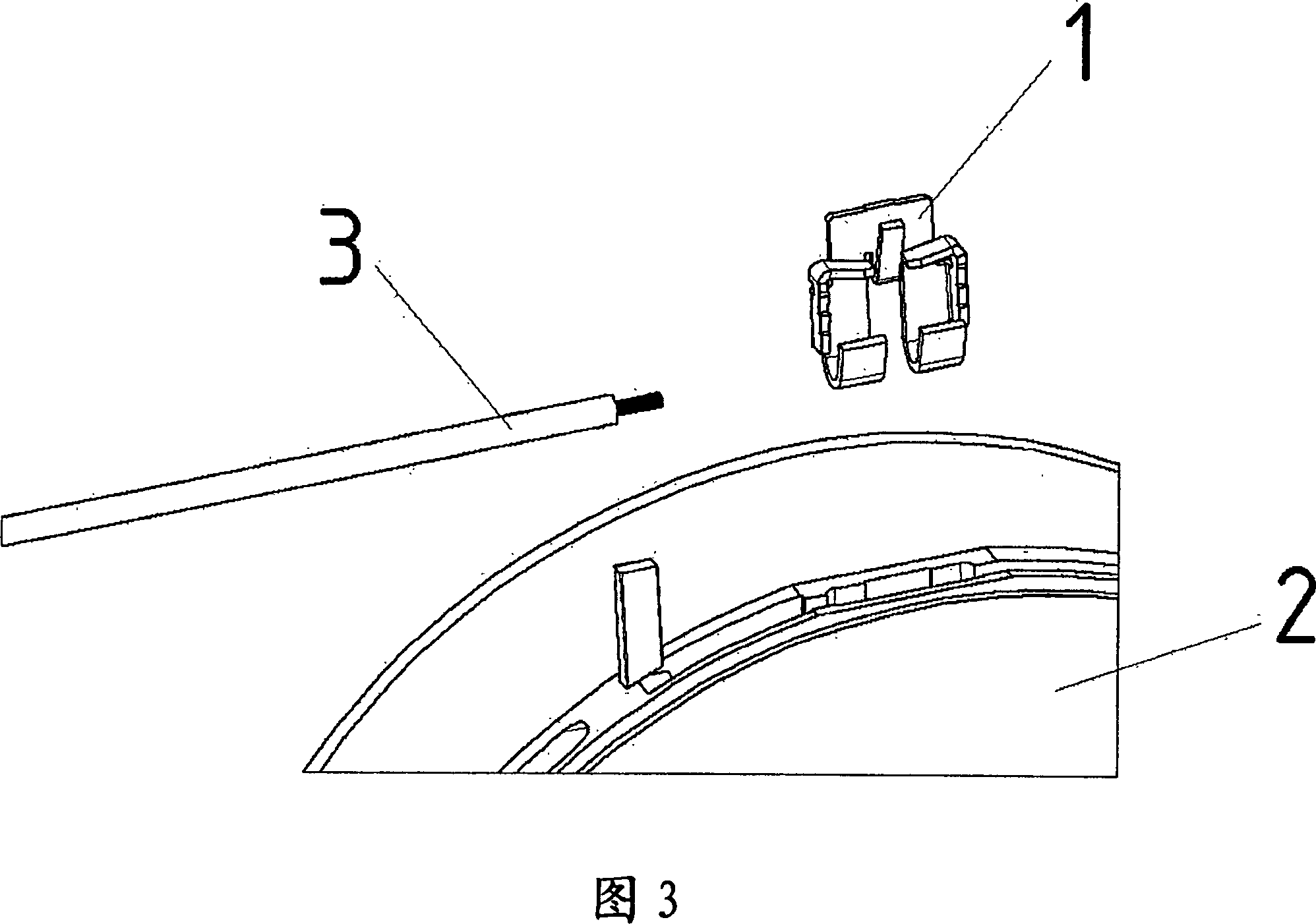

[0036] In Fig. 3 is shown a cable 3, comprising conductive litz wires and insulation, which can be inserted into the lower part of the sleeve 1 before the sleeve can be inserted into said coil support.

[0037] Three cables 3 are shown in FIG. 4 , which are connected to the sleeve 1 before the sleeve is inserted into the coil support 2 .

[0038] FIG. 5 shows an enlarged view of the cable 3 connected to the sleeve 1 , whereas FIG. 12 shows an enlarged view of the sleeve 1 itself without the cable. The left bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com