Artistic wood door and its manufacturing method

A technology for wooden doors and crafts, applied to craft wooden doors and their manufacturing fields, can solve the problems of easy cracks at the structure of the door core board and the inlaid strips, reduced door aesthetics, easy blistering at nail holes, and the like, so as to improve the aesthetics. , The effect of saving equipment and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described with reference to the drawings and embodiments:

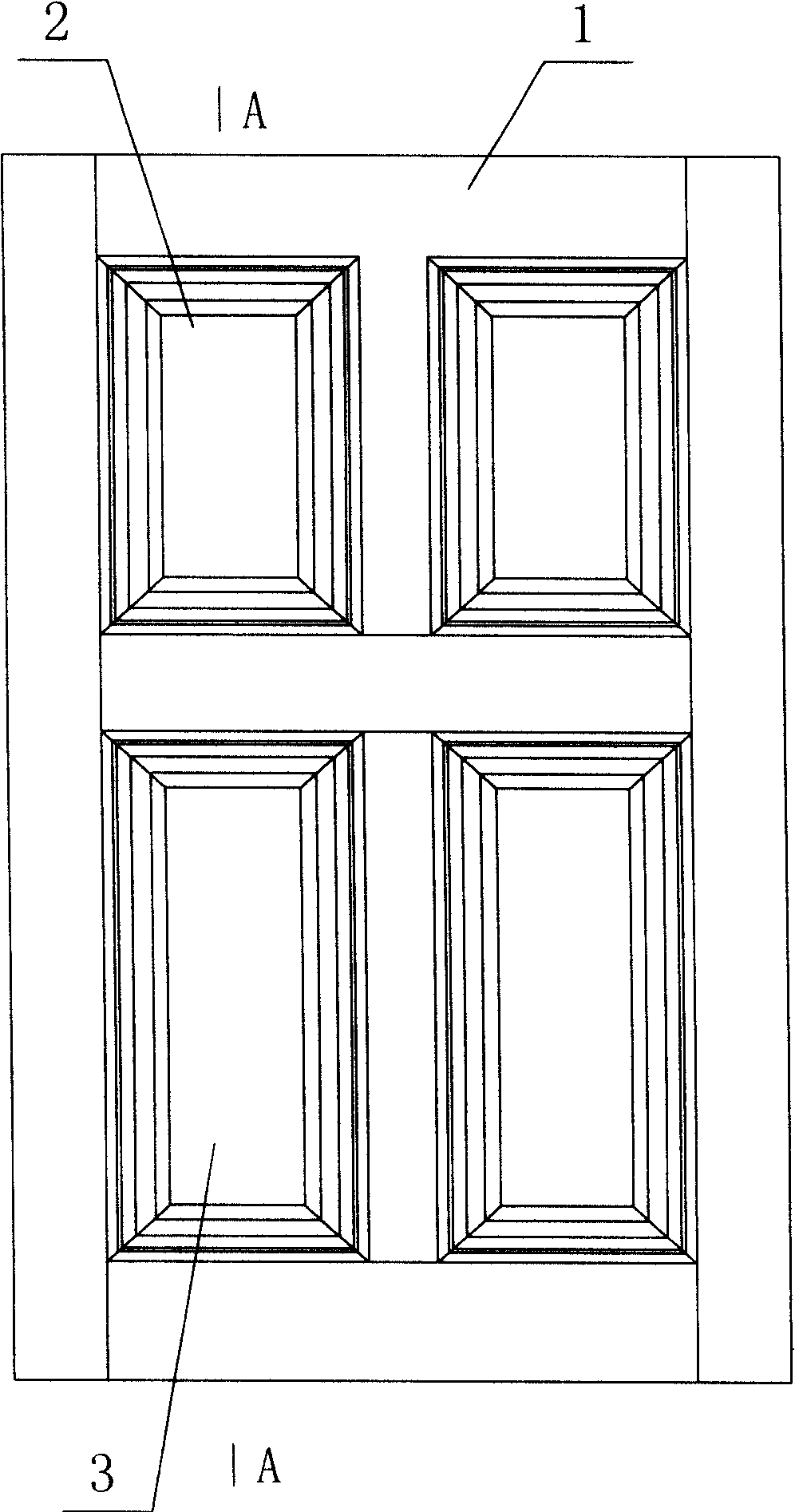

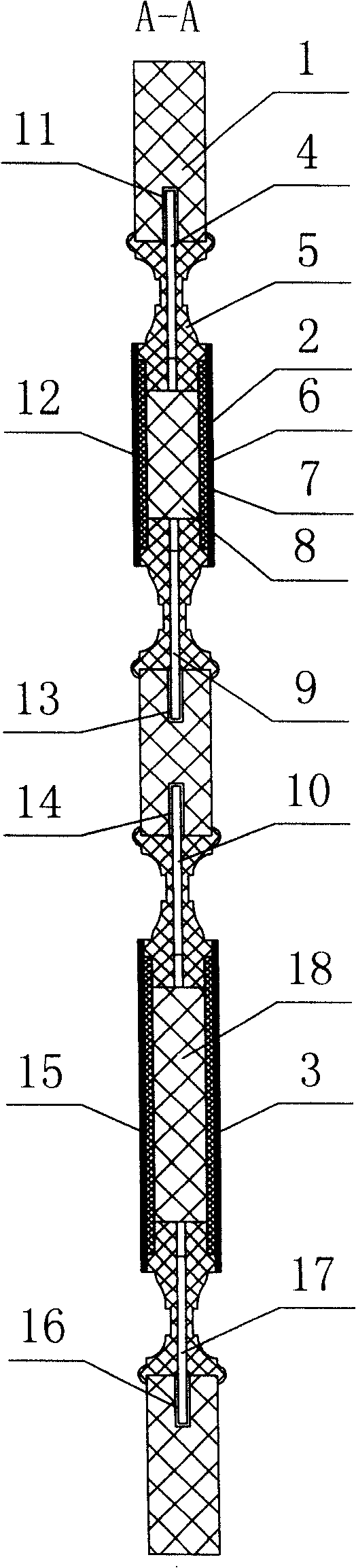

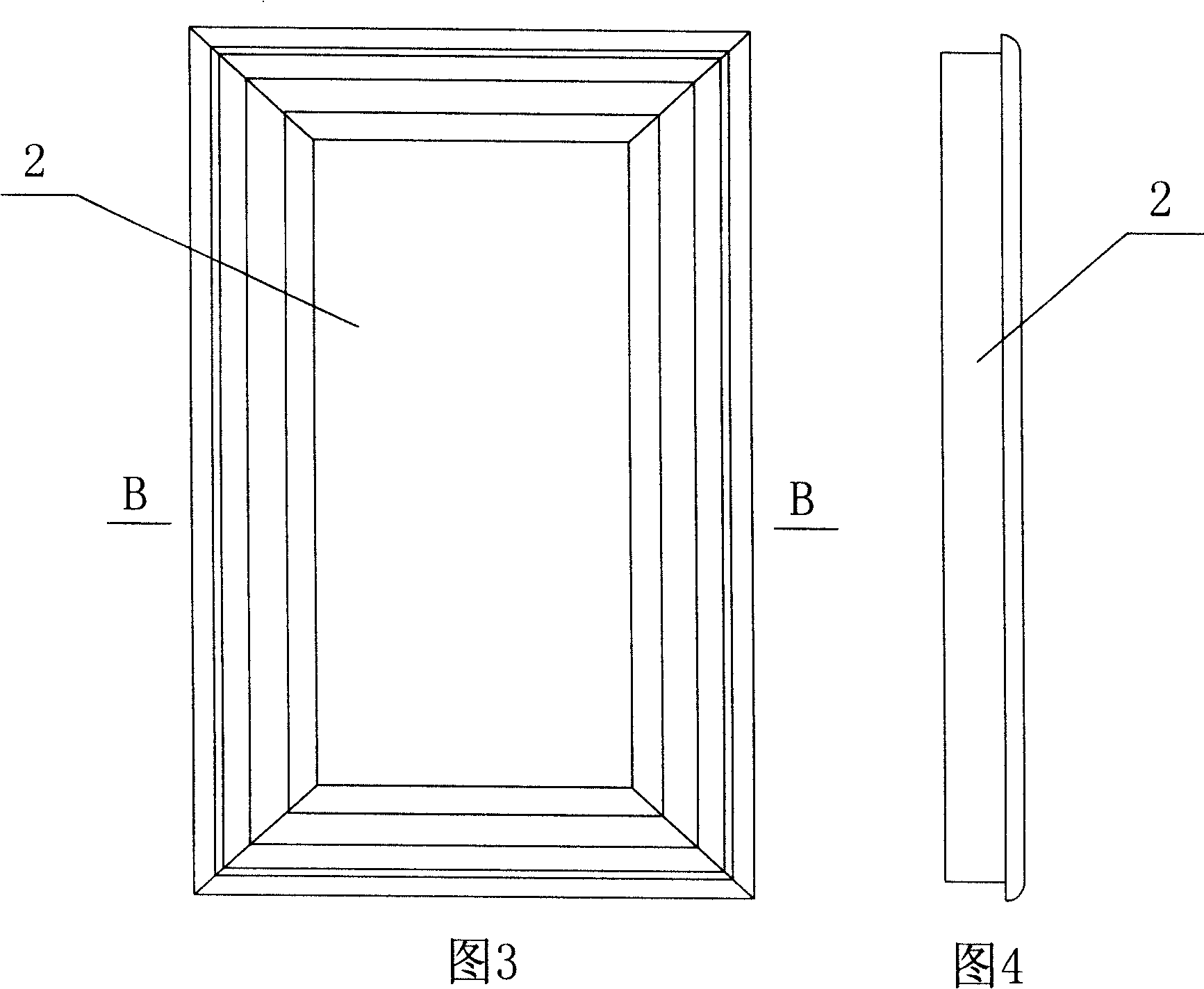

[0008] The craft wooden door of the present invention includes a door leaf frame, and a door core board is installed in the door leaf frame. The shape and number of the door core panels installed on each door are set according to the needs. There can be 4 door core panels on the front side of the door and 4 door core panels on the back side as shown in the figure. It can also be two on the front and the back. Arrange two door core panels on the left and right. The door core panels are installed in the front and back sides of the same plane in the door leaf frame 1, and each door core panel includes a panel 7 and a linear panel 5. The linear plate 5 can be an integral plate or a split plate. That is, the linear plate 5 is composed of four upper and lower, left and right sides. The two ends of each linear plate are inclined planes and are connected to each other. The body comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com