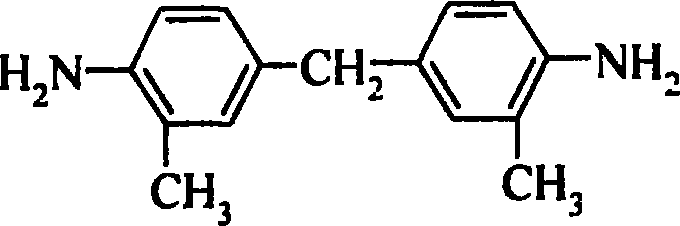

Preparation method of 3,3'-dimethyl-4,4'-diamino dibenzyl methane

A technology of diaminodiphenylmethane and dimethyl, which is applied in 3 fields, can solve the problems of high cost, many reaction by-products, and low yield, and achieve the effects of simple operation, low cost, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

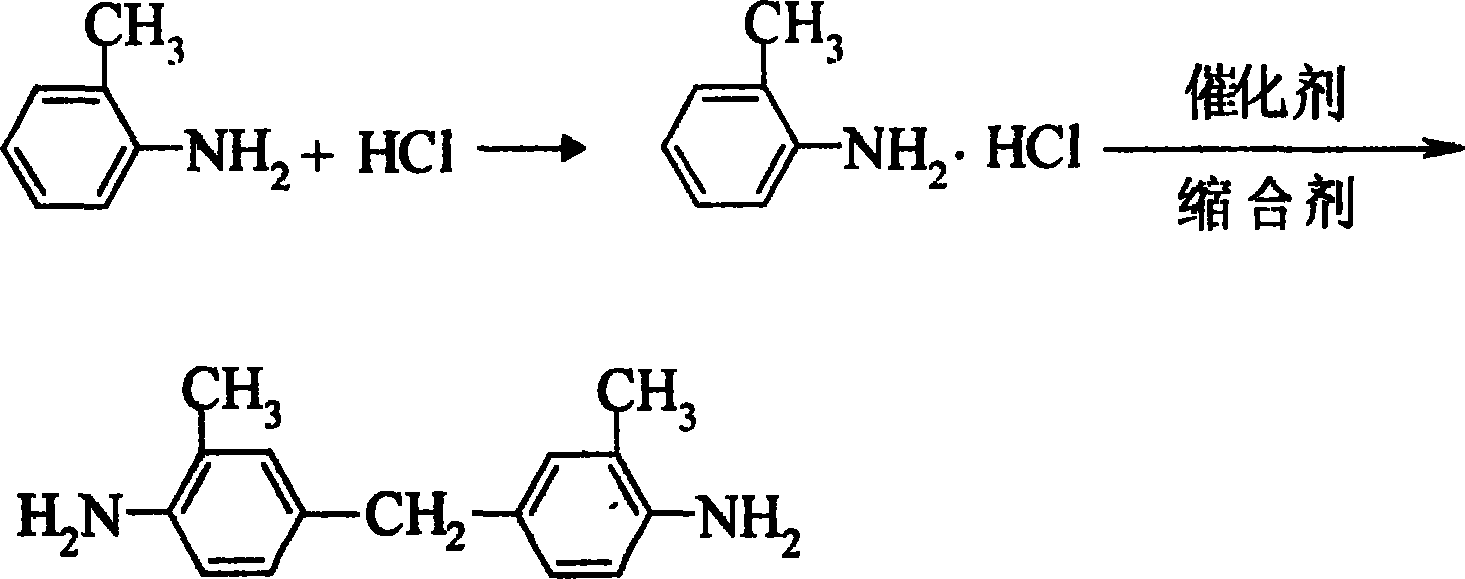

Method used

Image

Examples

Embodiment 1

[0022] Add 200ml of water and 100ml (1.0mol) concentrated hydrochloric acid into a 500ml reactor equipped with heating, stirring, thermometer, and reflux condenser, control the reaction temperature at 20-30°C, and add 106g (1.0mol) o-toluidine dropwise under stirring , continue to stir for 20 minutes, add 0.6g 4,4'-dimethylaminopyridine (DMAP), maintain the temperature, slowly drop in 40g (0.5mol) 37% formaldehyde solution, react for 2 hours after dropping, slowly heat up to 80-90°C, react for 3 hours. Cool to 25°C, adjust pH to 7 with 25% NaOH solution, and white solid precipitates out. Filter, wash with water, dry, obtain 3,3'-dimethyl-4,4'-diaminodiphenylmethane crude product 113g, add 800ml ethanol, dimethylformamide mixed solution (according to ethanol: dimethylformamide =5:1 volume ratio preparation) for recrystallization to obtain 3,3'dimethyl-4,4'-diaminodiphenylmethane white crystals 87g, yield 77%, purity 99.3% (HPLC), melting point 158 -159°C

Embodiment 2

[0024] Add 200ml of water and 100ml (1.0mol) of concentrated hydrochloric acid into a 500ml reactor with heating, stirring, thermometer, and reflux condenser. The reaction temperature is controlled at 20-30°C, and 106g (1.0mol) of o-toluidine is added dropwise under stirring. , continue to stir for 20 minutes, add 0.8g 4,4'-dimethylaminopyridine (DMAP), maintain the temperature and add 15g (0.5mol) paraformaldehyde in batches, react for 2 hours, slowly heat up to 80-90°C, and react 3 hours. Cool to 20°C, adjust pH to 7 with 25% KOH solution, and white solid precipitates out. Filter, wash with water, dry, obtain 3,3'-dimethyl-4,4'-diaminodiphenylmethane crude product 115g, add 400ml ethanol, dimethylformamide mixed solution (according to ethanol: dimethylformamide =1:1 volume ratio preparation) to carry out recrystallization to obtain 3,3'-dimethyl-4,4'-diaminodiphenylmethane white crystal 91g, yield 80.5%, purity 99.2% (HPLC), melting point 158-159°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com