Ultrasonic atomizing method and ultrasonic atomizing device

An ultrasonic wave and atomizer technology, applied in the field of ultrasonic atomization methods and ultrasonic atomizers, can solve the problem of increased fouling of the ultrasonic transducer 2, limiting the installation direction of the atomization generator 1 or the ultrasonic transducer 2, and inability to Issues such as self-flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

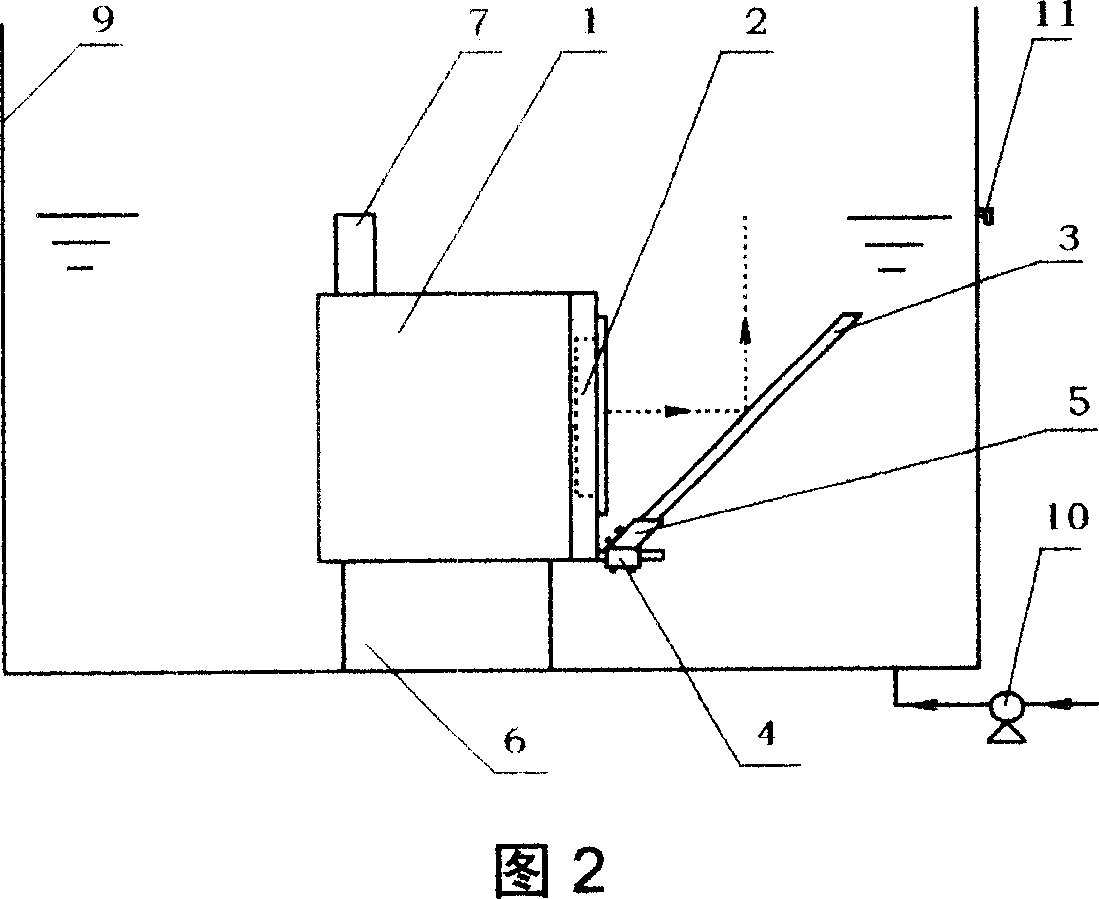

[0047] Embodiment 1: As shown in Figure 2, the atomization generator 1 is a square, and a first ultrasonic transducer sheet 2 is arranged on one side of the side shell of the atomization generator 1; The front of the first ultrasonic transducer sheet 2 is also provided with an upwardly inclined flat first reflector 3; The plane of the ultrasonic transducer 2 is at an angle of 45 degrees, so that the cavitation bubble can be flushed out perpendicular to the liquid surface; the lower part of the first reflection plate 3 is provided with a first displacement regulator 4 and a first angle regulator 5; The first reflection plate 3, the first displacement regulator 4 and the first angle regulator 5 are connected as one, and connected with the bottom of the atomization generator 1, placed on the platform 6 in the liquid container 9; the atomization generator 1 The upper part of the casing is provided with a water level detector 7; the bottom of the liquid container 9 is provided with...

Embodiment 2

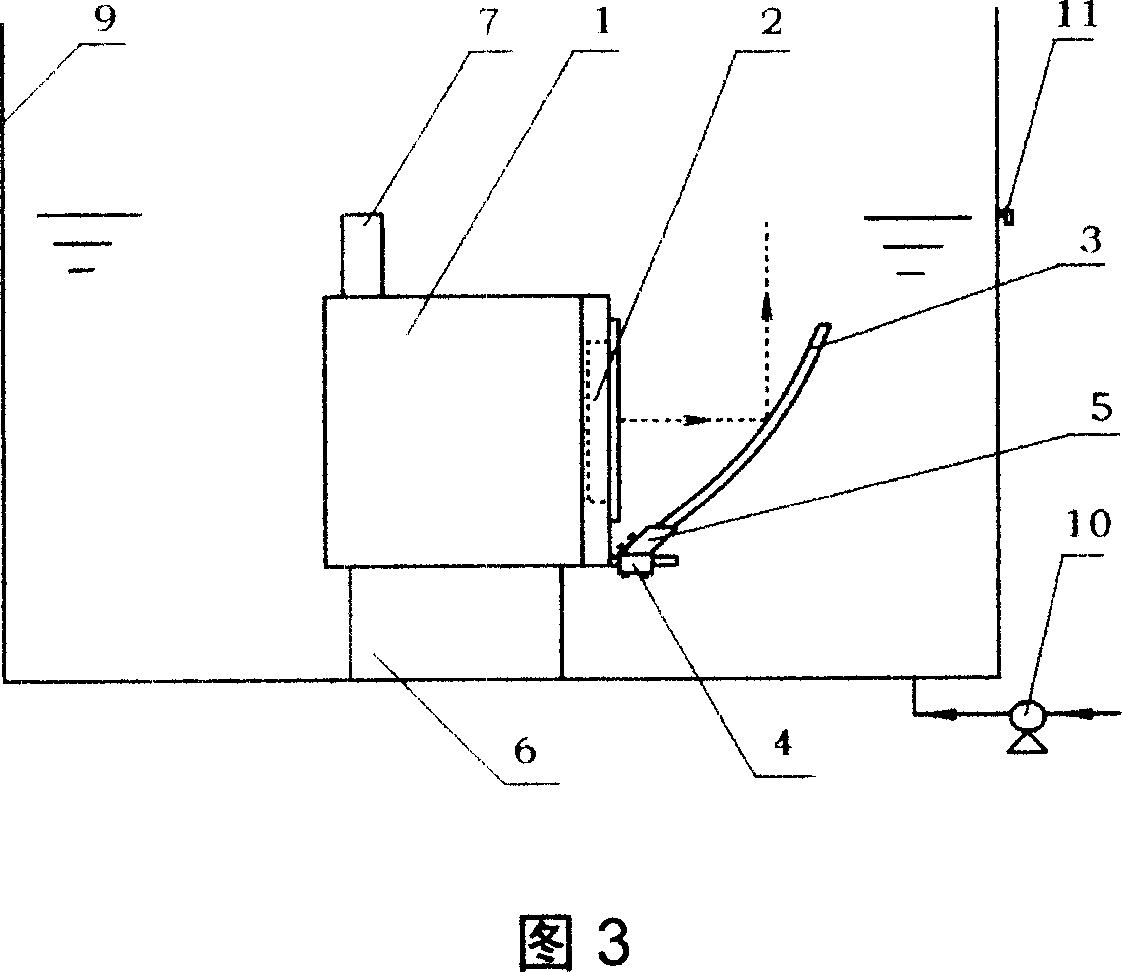

[0048] Embodiment 2: As shown in FIG. 3 , on the basis of Embodiment 1, the upwardly inclined flat plate-shaped first reflector 3 arranged directly in front of the first ultrasonic transducer sheet 2 is arranged to be upwardly inclined The other structures and connections are the same as those in Embodiment 1.

Embodiment 3

[0049] Embodiment three: as shown in FIG. 4, on the basis of embodiment one, a second ultrasonic transducer sheet 22 is set on the other side opposite to the side where the first ultrasonic transducer sheet 2 is located, and the second ultrasonic transducer sheet 22 is set. The front of the transducer sheet 22 is also provided with an upwardly inclined second reflector 33; the angle between the plane of the second ultrasonic transducer sheet 22 and the liquid surface is 60 degrees, and the plane of the second reflector sheet 33 and the second ultrasonic transducer sheet 22 planes form an angle of 60 degrees, so that cavitation bubbles can be flushed out in a direction perpendicular to the liquid surface; the second reflector 33 is provided with a second displacement regulator 44 and a second angle regulator 55; the first reflector 3. The first displacement adjuster 4 and the first angle adjuster 5 are integrated and arranged on the platform 6; the second reflector 33, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com