Method of manufacturing crystal oscillator and the crystal oscillator manufactured by the method

A technology for crystal oscillators and manufacturing methods, which is applied to power oscillators, instruments, electronic timers, etc., and can solve the problems that SPXO crystal oscillators cannot meet this specification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Various exemplary embodiments of the invention are described below.

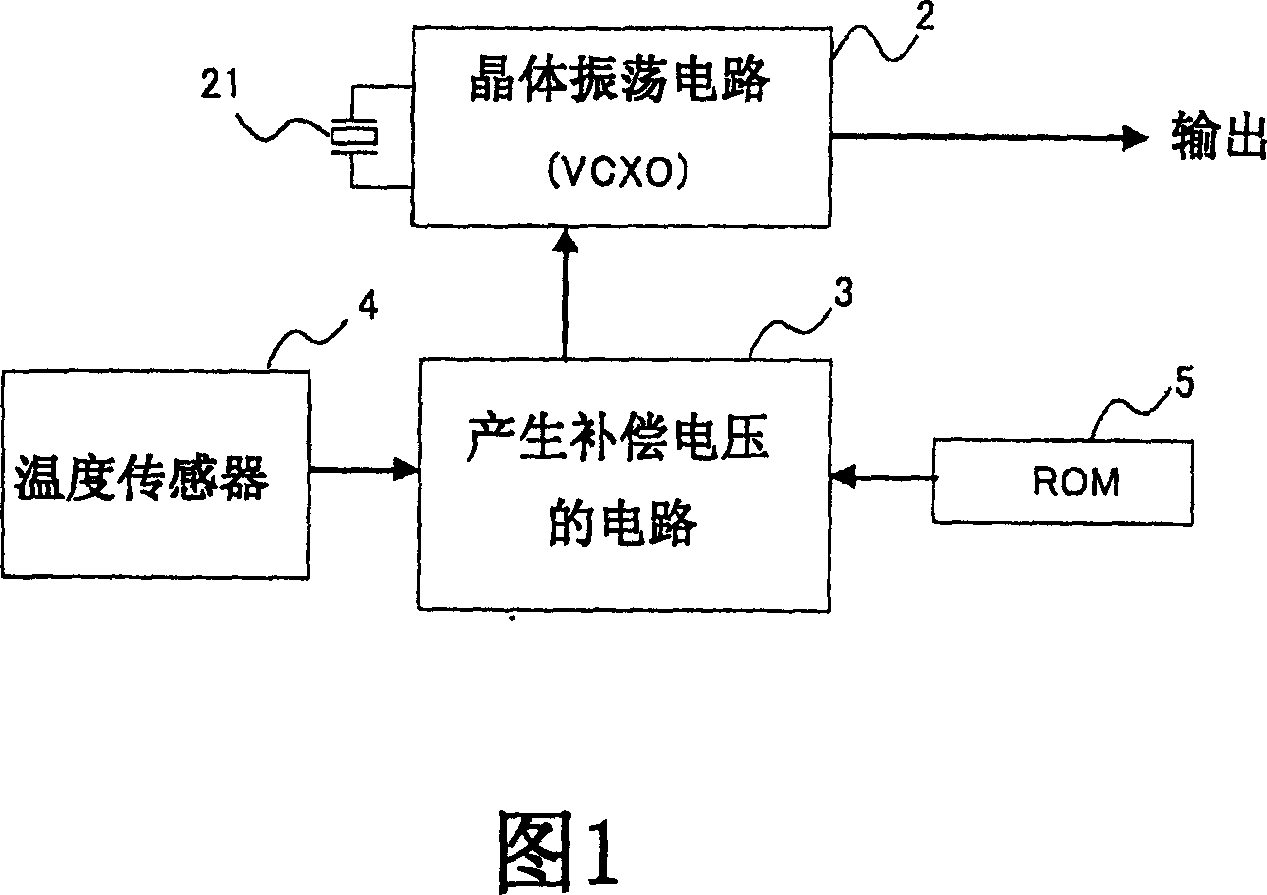

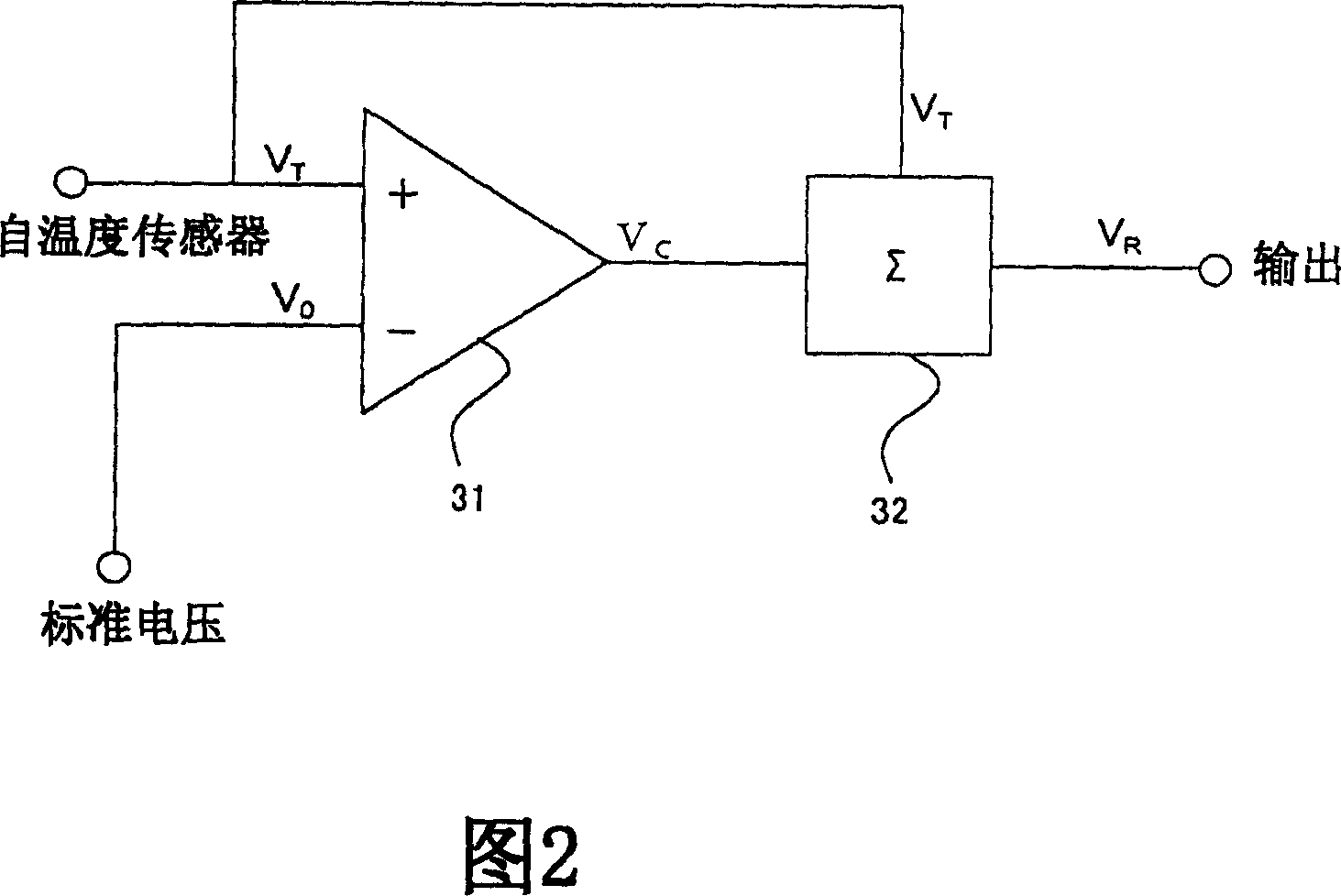

[0025] Figure 1 shows an example of a block diagram of an exemplary implementation of a crystal oscillator. As shown in FIG. 1 , a crystal oscillator 1 according to an exemplary embodiment includes a VCXO circuit 2 , a circuit 3 generating a compensation voltage, and a temperature sensor 4 .

[0026] The circuit 3 for generating the compensation voltage generates the compensation voltage according to a predetermined compensation curve including the quintic term, thereby compensating the temperature characteristic of the crystal resonator 2 . The wording "predetermined" means that the compensation curve can be determined before assembling the crystal resonator with the oscillation circuit without measuring the temperature characteristics of the crystal resonator to be assembled.

[0027] Therefore, the crystal oscillator according to this exemplary embodiment can be manufactured without measuring the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com