Method for detecting oil/water split-phase seepage flow resistance gradient

A detection method and gradient technology, applied in the field of reservoir physics research, can solve the problems of inability to distinguish the oil phase seepage resistance gradient and water phase seepage resistance gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

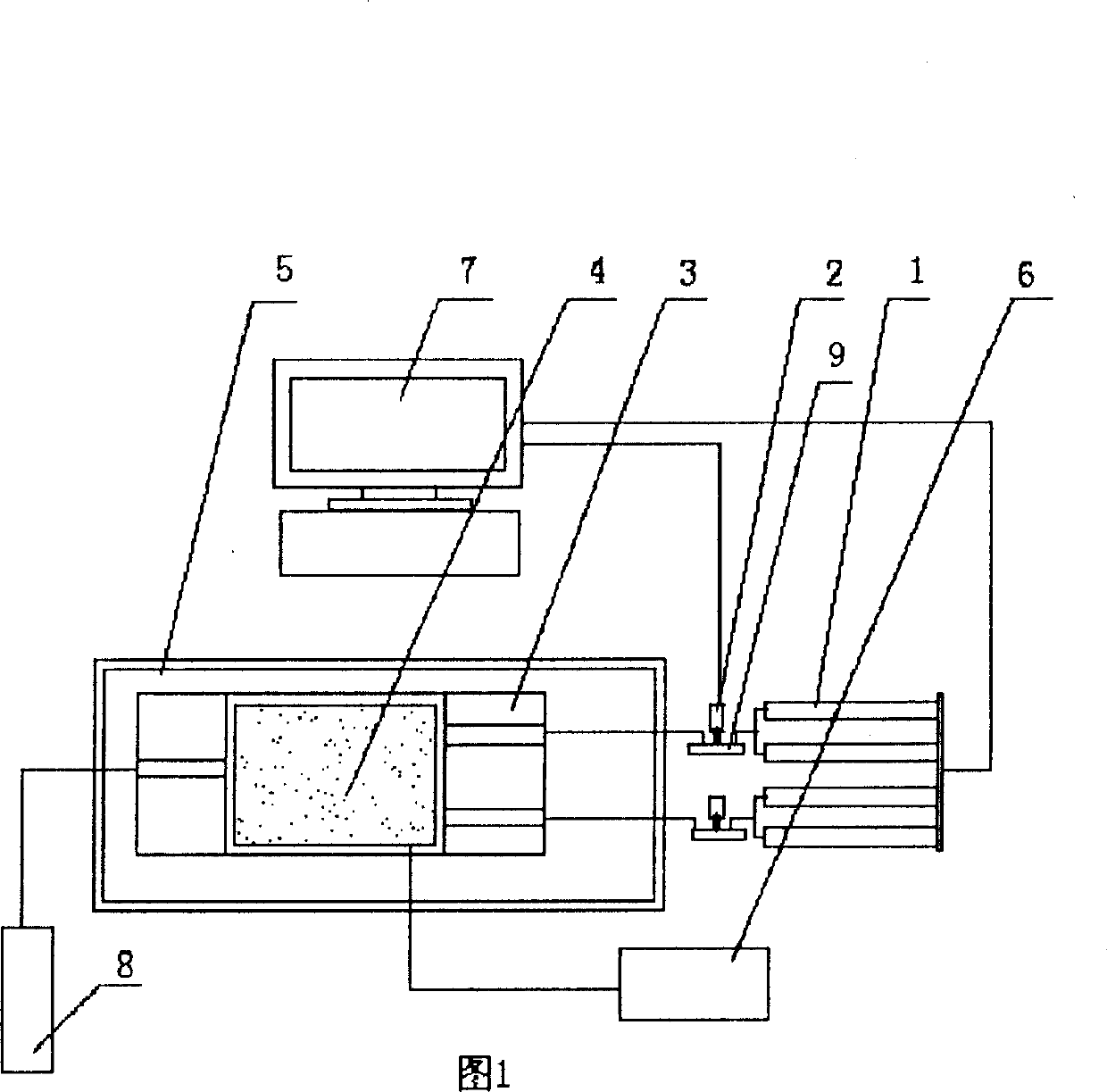

[0040] 1. Prepare the core sample and the corresponding oil and water samples, and prepare the experimental device according to Figure 1.

[0041] Experimental core: The core used in this example is Niu4-11 / 31, and the core parameters are shown in Table 1.

[0042]

Rock core number

Length(cm)

Diameter (cm)

Air permeability

(10 -3 um 2 )

Cow 4-11 / 31

4.990

2.540

6.78

[0043] Experimental water: 3% KCL aqueous solution, density 0.9992g / cm 3 , The viscosity is 1mPa.s at room temperature (22°C).

[0044] Experimental oil: It is made up of kerosene and white oil, with a density of 0.8537g / cm at room temperature 3 , The viscosity is 1.15mPa.s.

[0045] 2. Experimental determination steps

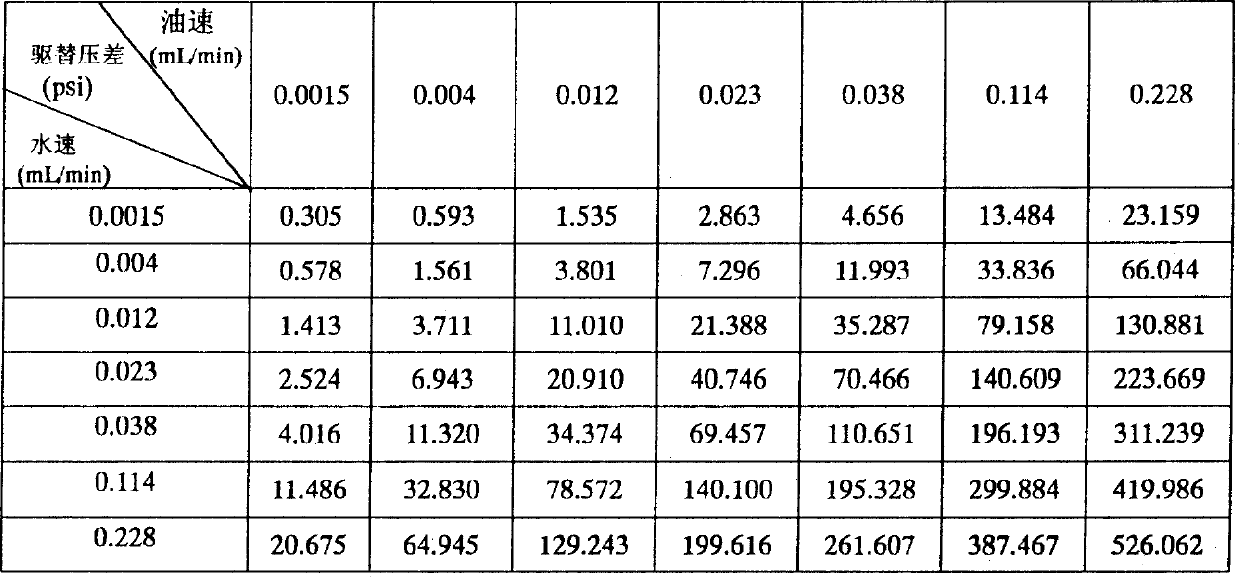

[0046] (1) By controlling the pump speed, keeping the oil speed constant at 0.0015mL / min, carry out displacement experiments with different water speeds (water speeds are: 0.0015, 0.004, 0.012, 0.023, 0.038, 0.114, 0.228 mL / min) Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com