In-situ substrate imaging

A substrate and substrate layer technology, which is applied in grinding machine tools, manufacturing tools, and components of grinding machine tools, etc., can solve problems such as unusable substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

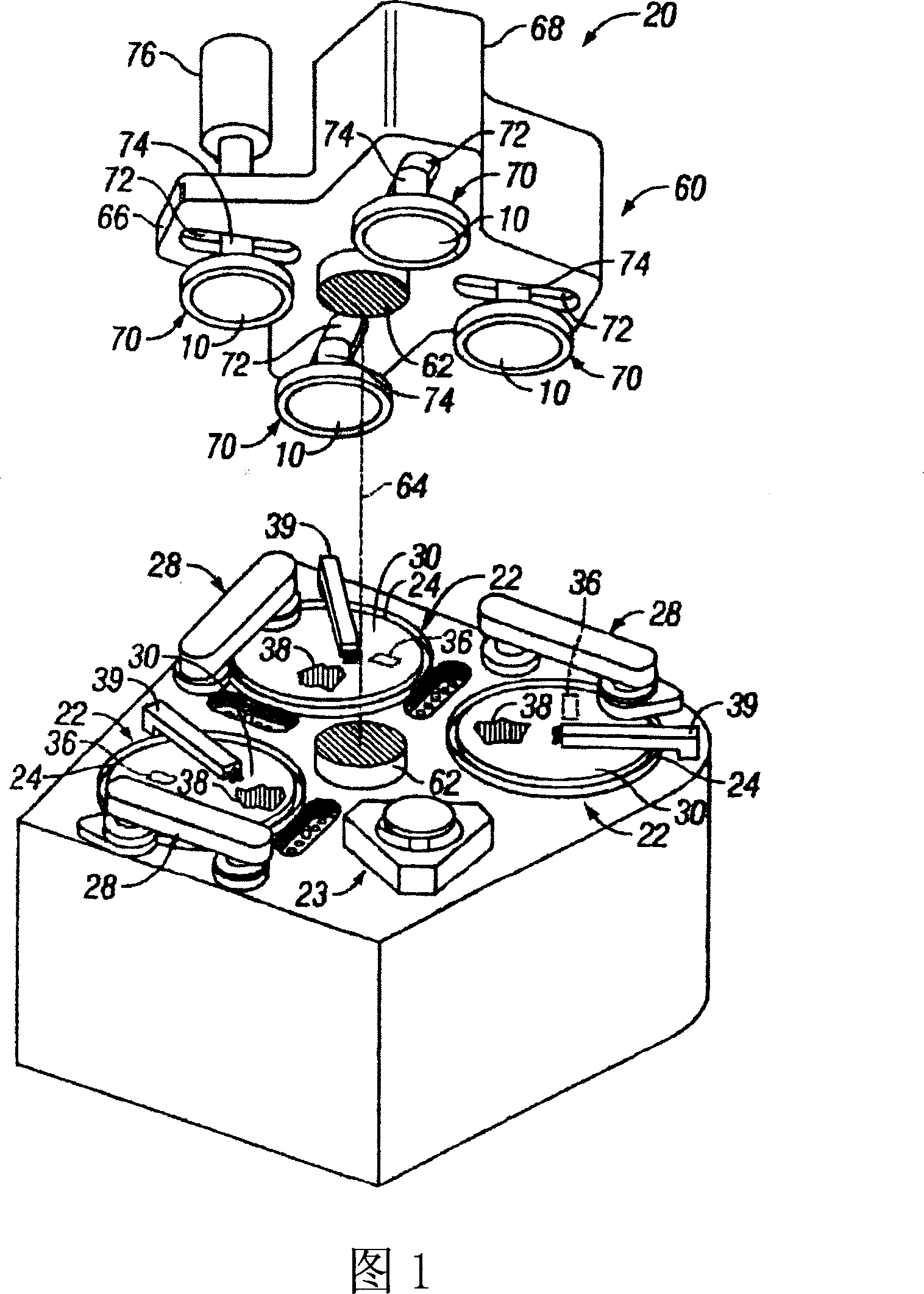

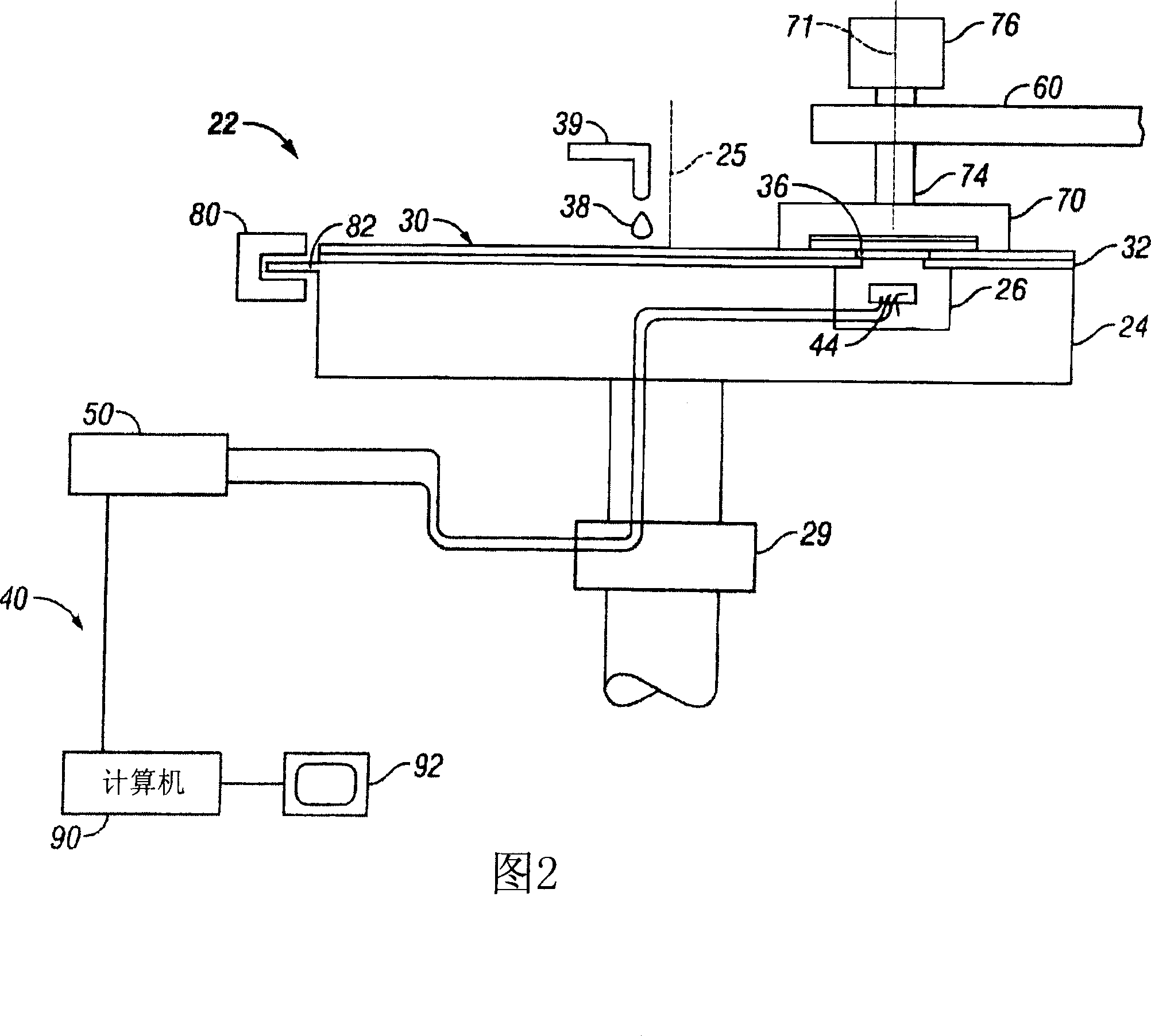

[0021] FIG. 1 shows a chemical mechanical polishing apparatus 20 capable of polishing one or more substrates 10 . The polishing apparatus 20 includes a series of polishing tables 22 and transfer tables 23 . The transfer station 23 transfers the substrate between the carrier head 70 and the loading device.

[0022] Each polishing station includes a rotatable platen 24 on which a polishing pad 30 is disposed. The first and second stations may include a two-layer polishing pad with a harder, durable outer surface or a fixed abrasive pad embedded with abrasive particles. The last polishing station may include a relatively soft pad. Each polishing station may also include a pad conditioning device 28 for maintaining the condition of the polishing pad to effectively polish the substrate.

[0023] A rotatable multi-head carousel 60 supports four carrier heads 70 . By means of a carousel motor assembly (not shown), the carousel is rotated about a carousel shaft 64 via a central co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com