Ozone injection method and system

A technology of ozone and injectors, applied in the direction of ozone preparation, chemical instruments and methods, transportation and packaging, etc., can solve the problems of expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

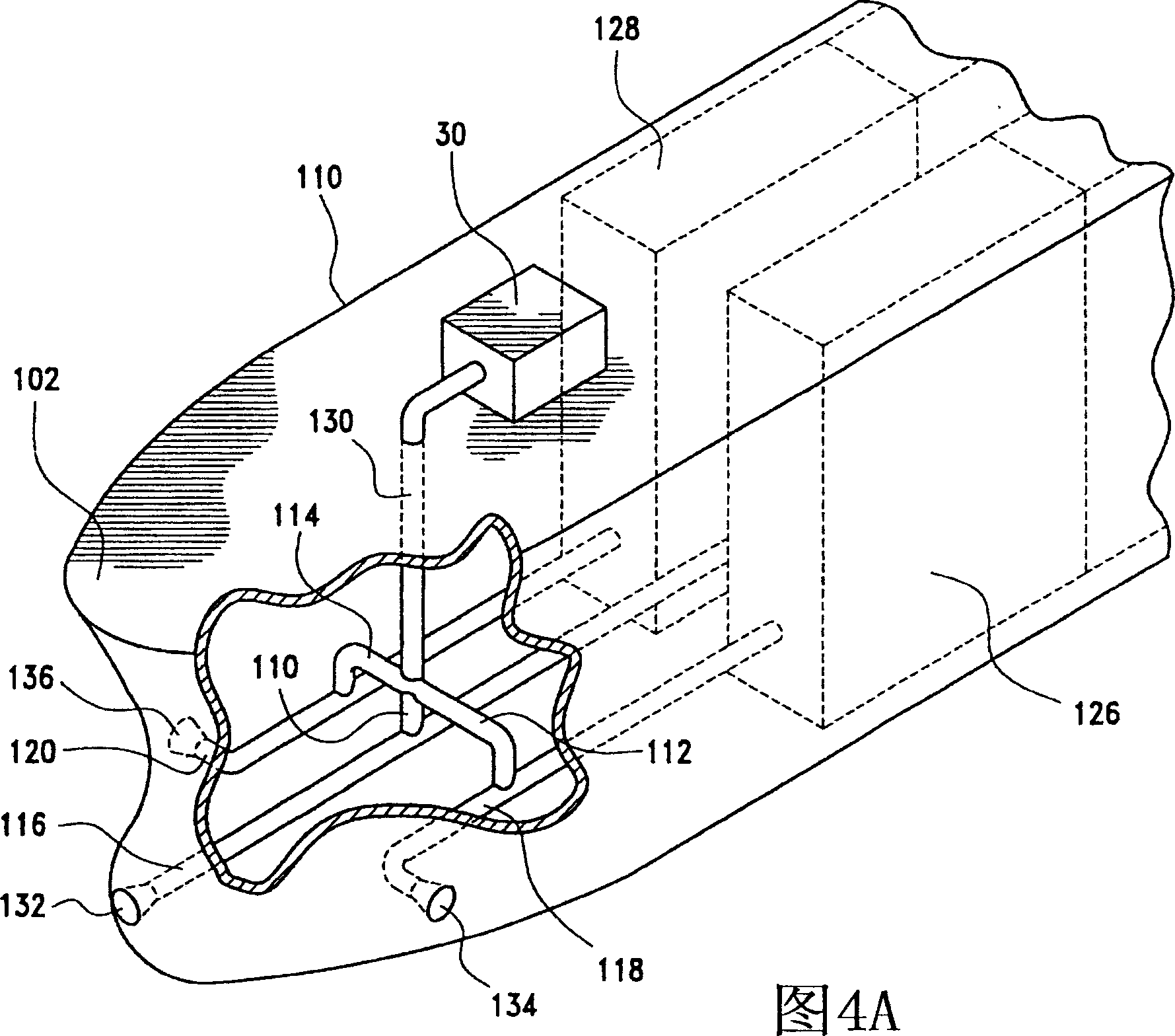

[0043] Ozone is produced at a pressure of about 10-12 psi above atmospheric pressure. Deviations in this pressure can negatively affect the output of ozone. Ballast water is pumped into the ship at variable pressure, which can be high when the tanks are filled. Relatively low pressure ozone / oxygen or ozone / air mixtures can be pressurized to higher pressures by very specialized and expensive equipment (due to the corrosive nature of ozone and more importantly the fact that ozone decomposes under the heat of compression ).

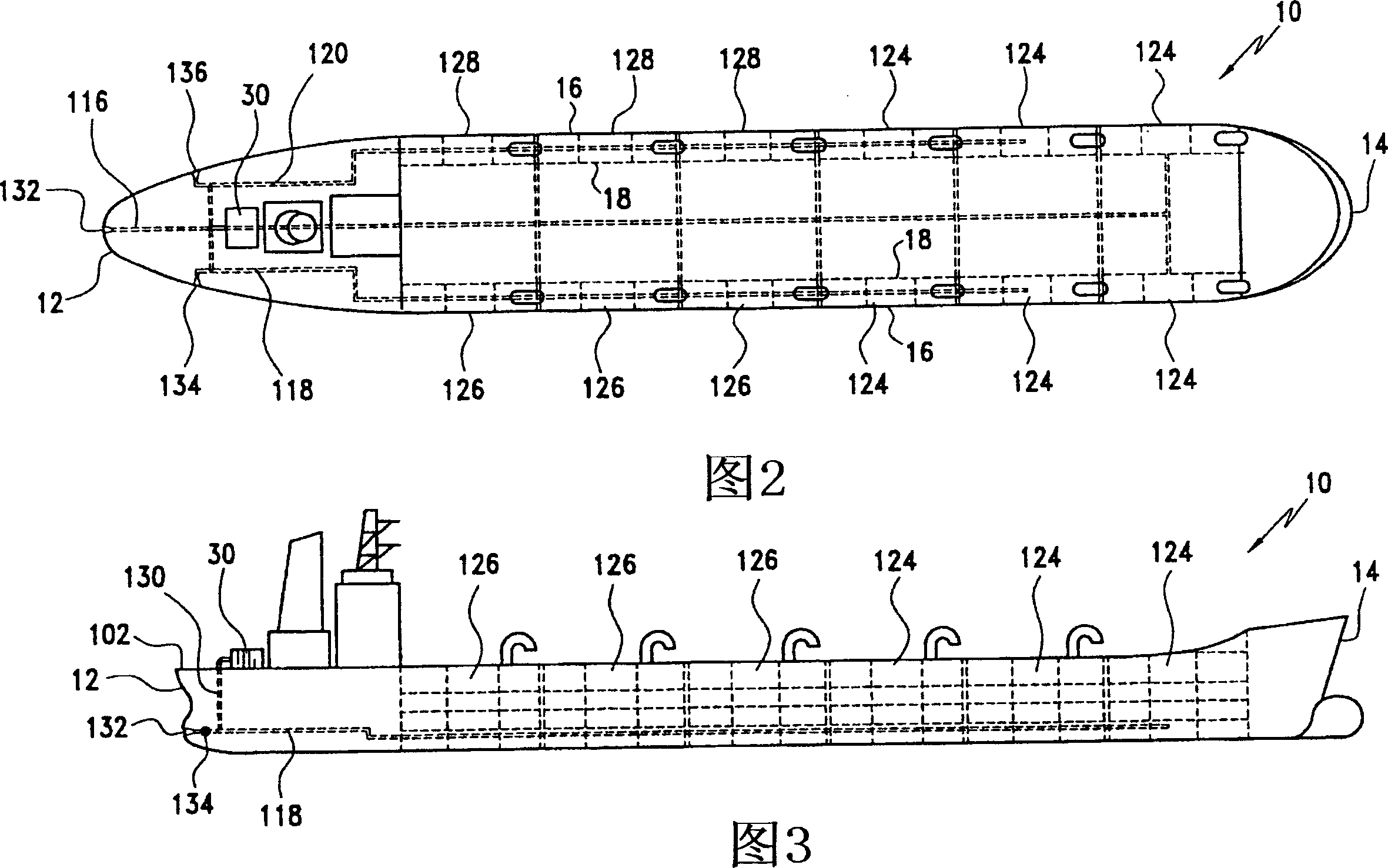

[0044] In one embodiment, the invention relates to ozone ballast water treatment. The proposed NAIS revision defines "ballast water" as "any water (and its suspended matter) used to maintain the balance and stability of a vessel". In another definition, "ballast water" is A) the containment of water on the deck of a vessel which is used to control the trim, list, draft, stability or stress of the vessel containing substances suspended in such water; and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gas content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com