Non-toxic or low-toxicity anti-fouling coating prepared by utilizing Chinese medicinal crop gallnut solvent extract

A kind of antifouling paint and gallnut technology, which is applied in non-toxic and low-toxic new antifouling paint, Chinese herbal medicine Gallnut extract as marine antifouling agent, can solve the problems of difficult sampling of marine organisms, high price, low output and distribution, etc. , to achieve broad anti-fouling and broad-spectrum activity, reduce pollution and harm, and reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

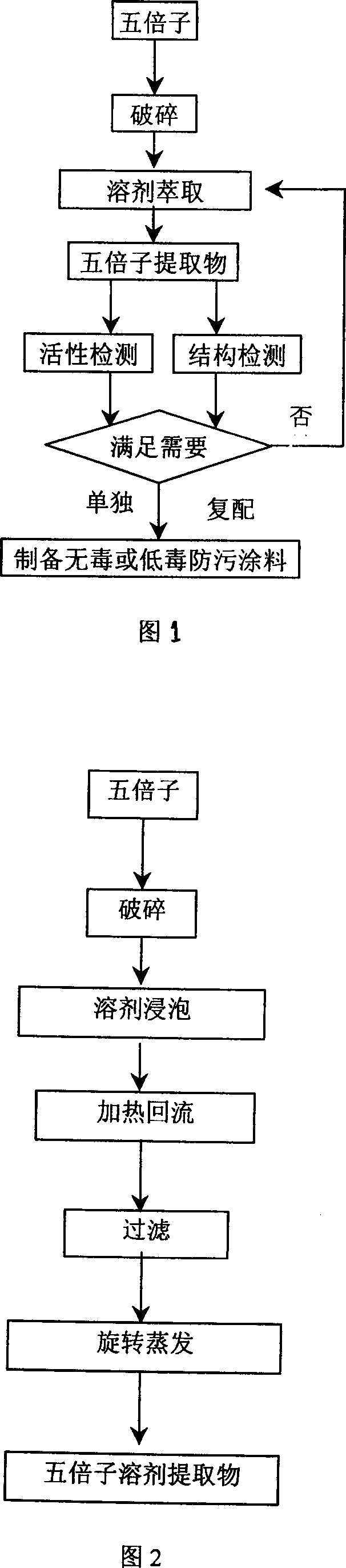

Method used

Image

Examples

Embodiment 1

[0033] Preparation of water extract of Galla Chinensis

[0034] Use a high-speed micro pulverizer to crush 800 grams of gall shells. After crushing, pass through a 60-mesh sieve. Add 500 grams of the upper part of the sieve to the Soxhlet extractor. Add 2000 ml of double distilled water, soak for 24 hours, and boil and reflux for 10 hours. Then the extract is filtered out, placed in a rotary thin film evaporator, concentrated under reduced pressure at 0.9 Mpa, and dried naturally at room temperature to prepare a paste to obtain a water extract of Galla Chinensis.

Embodiment 2

[0036] Preparation of Galla Chinensis Ethanol Extract

[0037] Use a high-speed micro pulverizer to crush 1000 grams of gall shells. After crushing, pass through a 60-mesh sieve. Take 500 grams of the upper part of the sieve and add it to a Soxhlet extractor. Add 2000 ml of ethanol, soak for 48 hours, and boil and reflux for extraction for 20 hours. Then the extract is filtered out, placed in a rotary thin film evaporator, concentrated under reduced pressure at 0.9Mpa into a paste, and dried naturally at room temperature to obtain an ethanol extract of Galla Chinensis.

Embodiment 3

[0039] Preparation of Galla Chinensis Ethyl Acetate Extract

[0040] Use a high-speed micro pulverizer to crush 900 grams of gall shells. After crushing, pass through a 60-mesh sieve. Take 500 grams of the upper part of the sieve and add it to a Soxhlet extractor. Add 2000 ml of ethyl acetate, soak for 24 hours, and boil and reflux for 20 hours. Then the extract is filtered out, put into a rotary thin film evaporator, concentrated under reduced pressure at 0.9Mpa into a paste, and air-dried naturally at room temperature to obtain an ethyl acetate extract of gall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com