Ammonium nitrate waste water treatment method

A technology for wastewater treatment and ammonium nitrate, applied in heating water/sewage treatment and other directions, can solve problems such as environmental pollution, ammonia treatment fails to meet discharge standards, etc., and achieves the effect of reducing energy consumption and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

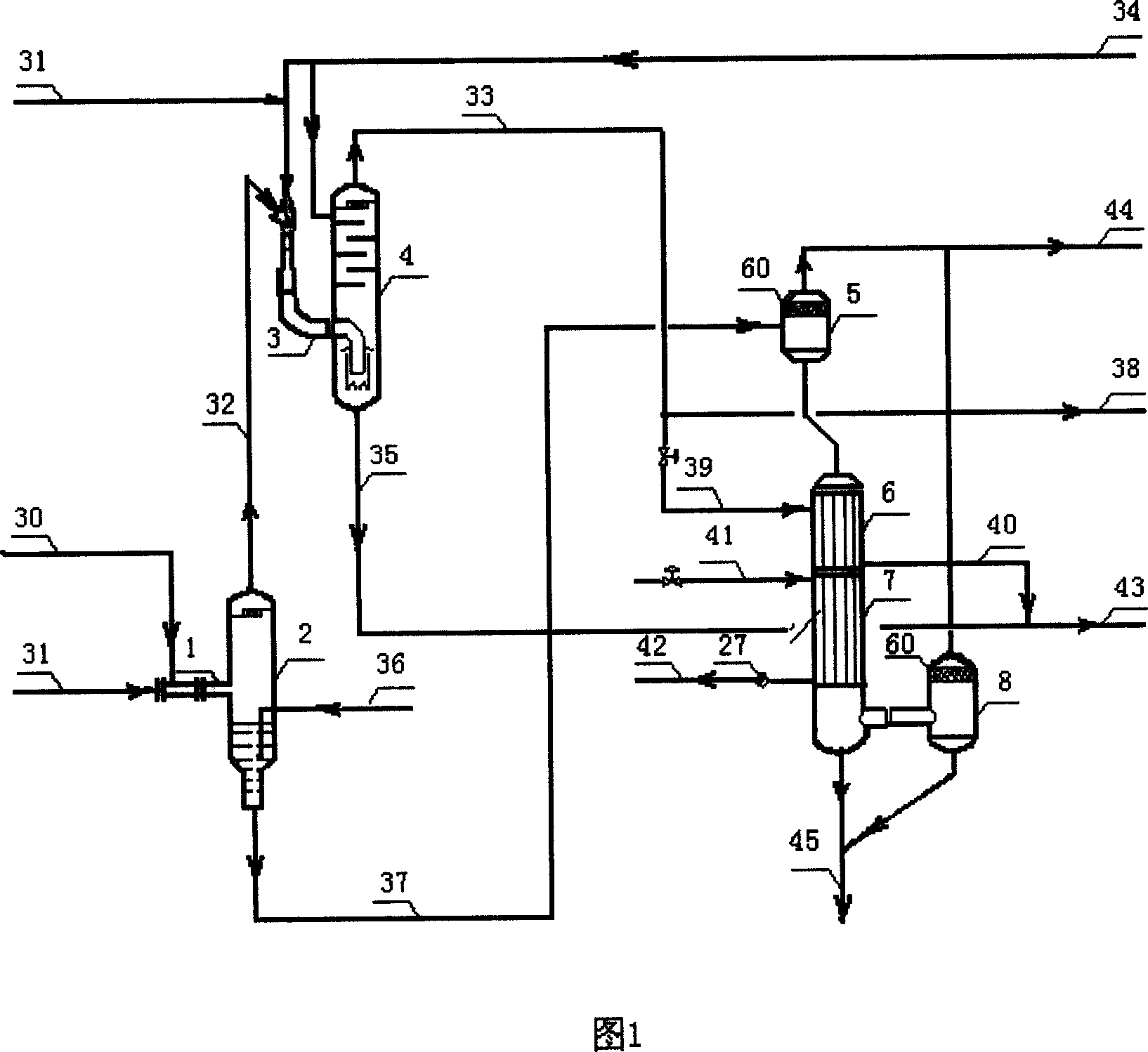

Method used

Image

Examples

Embodiment 1

[0029] Three-effect evaporation and condensation process

[0030] Feed material: secondary steam (1.4barabs) 9740kg / h (ammonium nitrate 1%, ammonia 0.5%)

[0031] Evaporation condensate: 15260kg / h (ammonium nitrate 1%, ammonia 0.5%)

[0032] Consumption: acid: 772kg / h (60% concentration)

[0033] Electricity: 28kw / h

[0034] Cooling water: 500m 3 / h(Δt=10℃)

[0035]Treated wastewater: 22422kg / h (ammonium nitrate 30ppm)

[0036] Recovered ammonium nitrate solution: 3350kg / h (25% concentration).

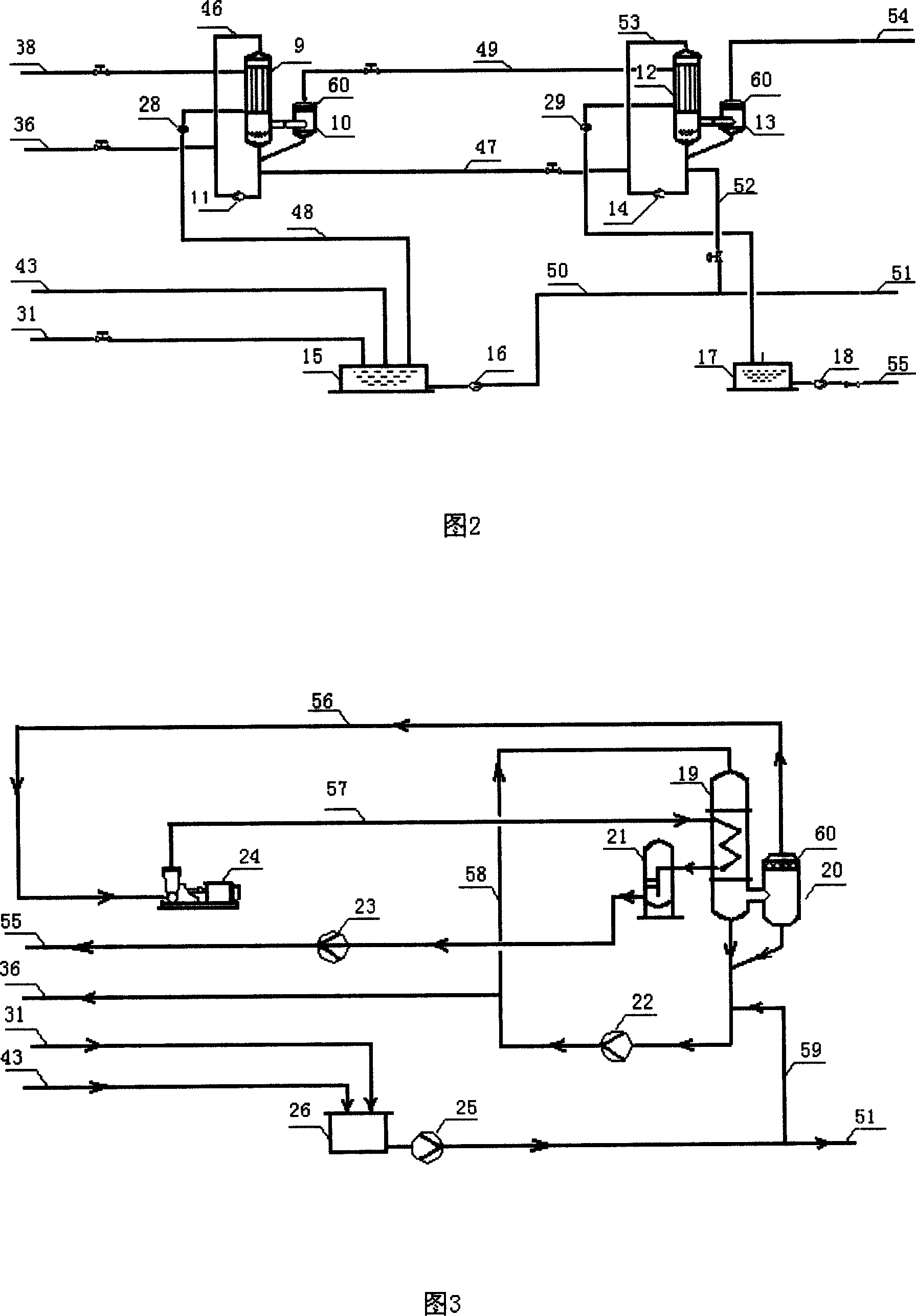

Embodiment 2

[0038] mechanical compression process

[0039] Feed: condensate: 25000kg / h (ammonium nitrate 1%, ammonia 0.5%)

[0040] Consumption: 60% nitric acid: 72kg / h

[0041] Electricity: 570kw / h

[0042] Treated wastewater: 22204kg / h (ammonium nitrate: 30ppm)

[0043] Recovered ammonium nitrate solution: 5568kg / h (concentration 15%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com