Bamboo charcoal antibacterial deodorizing shoes

A technology of bamboo charcoal and shoe uppers, applied in shoe uppers, footwear, shoe soles, etc., can solve problems such as unsatisfactory effects and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

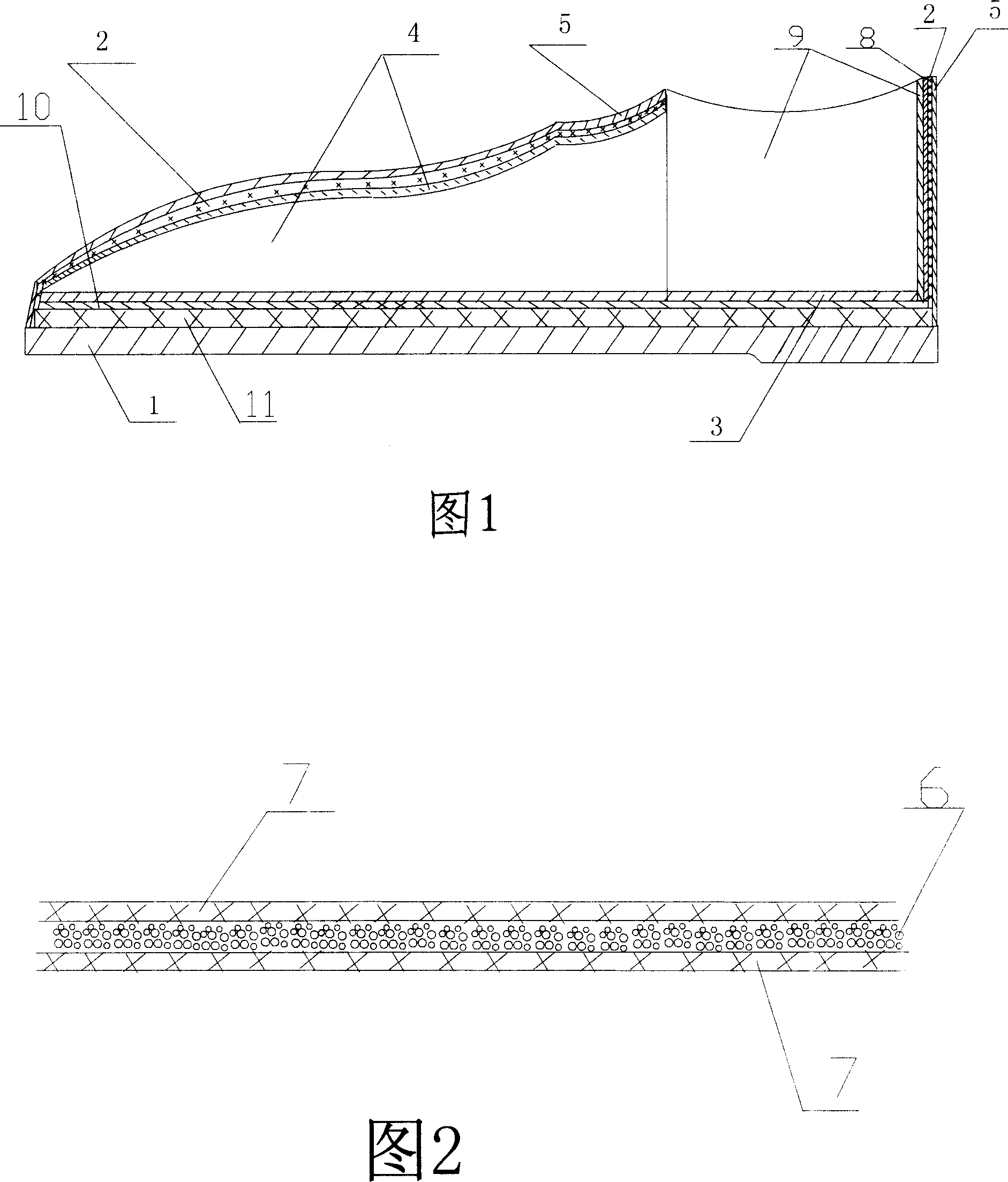

[0010] Fig. 1 is a kind of bamboo charcoal antibacterial and deodorant shoes, the bamboo charcoal is processed into particle fineness to be about 50 meshes, and 5% nano-scale titanium oxide micropowder is mixed in during this period, first as shown in Fig. 2 with two layers of non-woven fabric 7 The granular bamboo charcoal 6 is bonded to form the upper interlayer 2, and the fine granular bamboo charcoal 6 is bonded to form the sole interlayer 10 with two layers of pure cotton cloth 7. Made of bamboo fiber cloth, the upper and upper interlayer 2 are placed between the front lining, the rear lining and the cowhide upper, and then the upper is stitched together to form the upper. The outsole 1 is a rubber material covered by two layers of cotton cloth 7 The bamboo charcoal midsole 11 formed by the bonding of fine granular bamboo charcoal 6 covers the midsole 10 again, and then covers a layer of bamboo fiber cloth as the bottom 3, and the upper of a shoe and the sole are bonded to...

Embodiment 2

[0012] Fig. 1 is a kind of bamboo charcoal antibacterial deodorant shoe, and bamboo charcoal is processed into particle fineness and is about 60 orders, earlier as shown in Fig. Two layers of linen cloth 7 bond the fine granular bamboo charcoal 6 to form a midsole 10, the vamp 5 is canvas, the front section lining 4 is a layer of pure cotton cloth, and the rear section lining 8 is made of one layer of bamboo fiber cloth. The upper interlayer 2 is placed between the front lining, the rear lining and the cowhide upper, and then the upper is stitched together to form the upper. The outsole 1 is a rubber material covered with antibacterial and deodorizing Chinese medicinal materials and bamboo pulp. The finished Chinese medicine bamboo fiber midsole 11 covers the midsole 10 again, and then covers a layer of linen as the bottom 3, and the upper of a shoe and the sole are sewed together to become bamboo charcoal antibacterial and deodorizing sports shoes.

Embodiment 3

[0014] Fig. 1 is a kind of bamboo charcoal antibacterial deodorant shoe, and bamboo charcoal is processed into particle fineness and is about 80 orders, earlier as shown in Fig. Two layers of bamboo fiber cloth 7 bond the fine granular bamboo charcoal 6 to form a midsole 10, the vamp 5 is pigskin, the front section lining 4 is a layer of bamboo fiber cloth, and the rear section lining 8 is made of pure cotton cloth. The upper interlayer 2 is placed between the front lining, the rear lining and the cowhide upper, and then the upper is stitched together to form the upper. The outsole 1 is a rubber material covered with antibacterial and deodorizing Chinese medicinal materials and bamboo pulp. The Chinese herbal medicine bamboo fiber middle bottom 11 of becoming covers the midsole 10 again, and then covers one deck pure cotton cloth as the base 3, and the upper of a shoe and the sole are bonded to be bamboo charcoal antibacterial and deodorizing leather shoes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com