Cotton picking machine

A technology for picking machines and cotton, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc. It can solve the problems of cotton quality decline, difficult adjustment of suction, loss of cotton wool, etc., and achieves the advantages of reducing labor intensity, improving efficiency, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

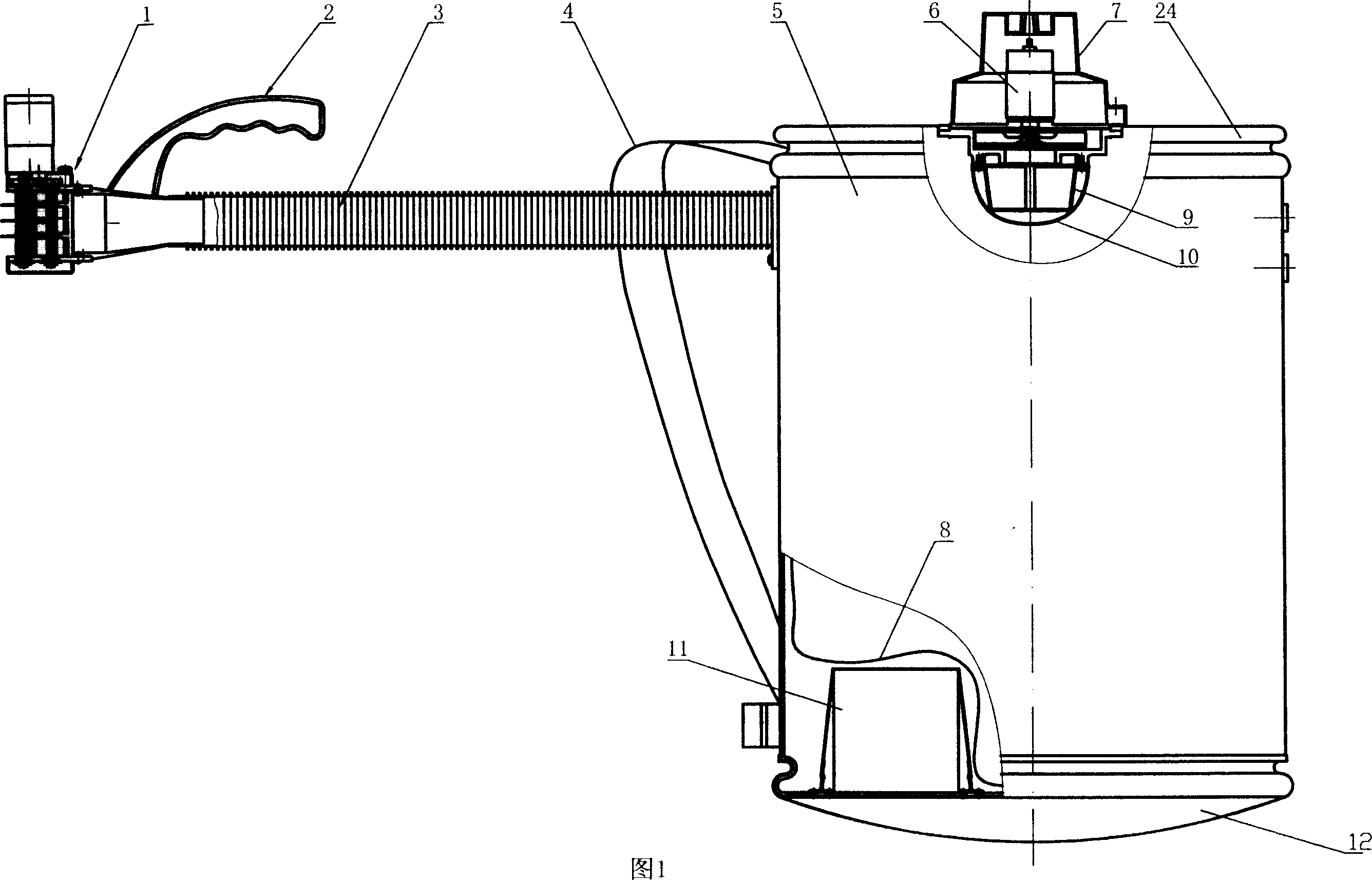

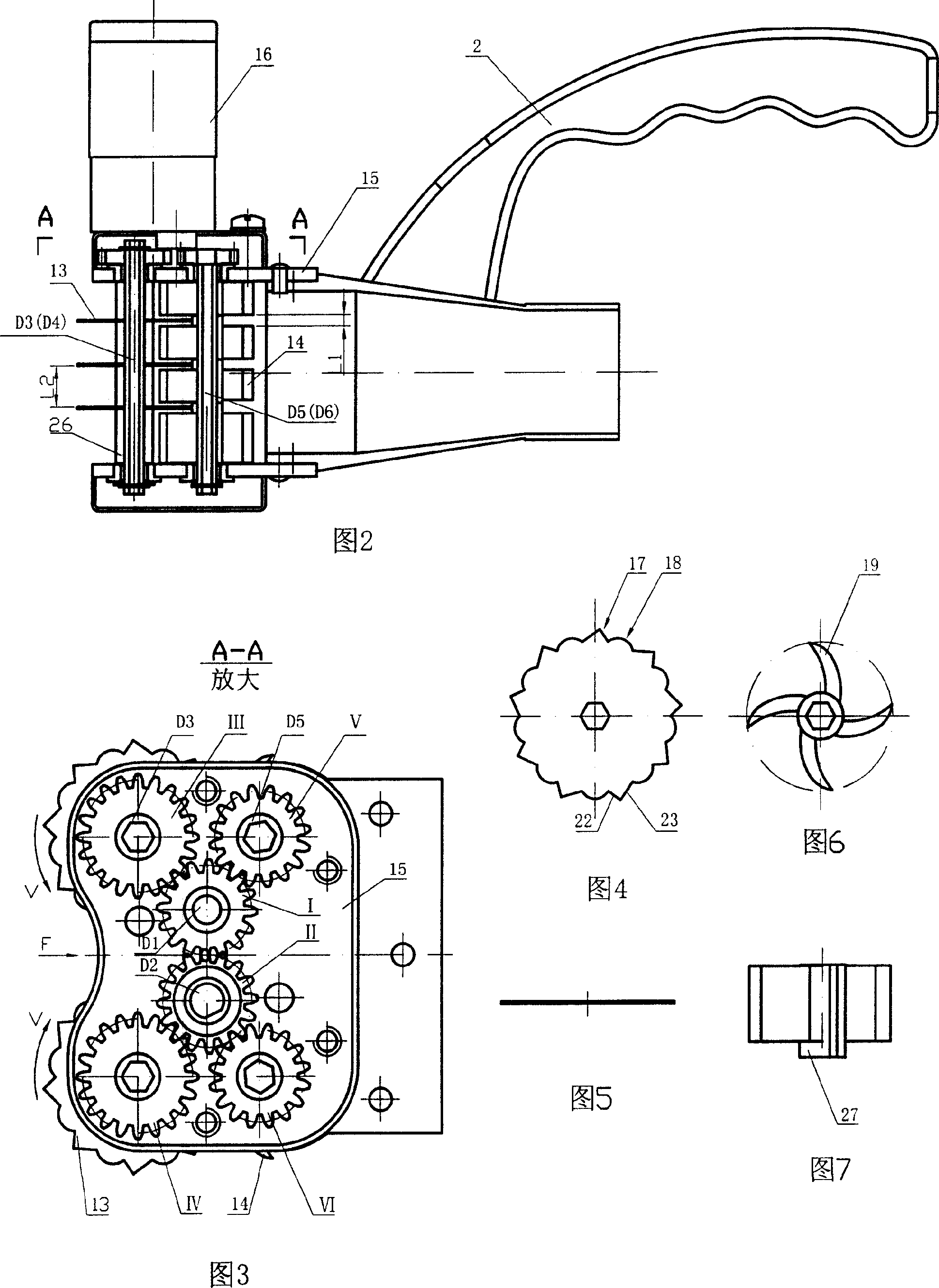

[0026] 1, the conveying hose 3 communicates with the electric picking head 1 and the cotton storage barrel 5, and the negative pressure fan 6 is placed at the corresponding air suction port position on the cotton storage barrel cover 24 at the upper end of the cotton storage barrel. The DC power supply 11 places the bottom in the cotton storage bucket 5, and is connected with the motor 16 on the electric picking head 1 and the negative pressure blower 11 respectively by wire, to provide power to them. The outside of the negative pressure fan 6 is provided with a fan cover 7, and the dust-proof cover is connected to the inside of the corresponding cotton storage barrel through a dust-proof bracket to prevent the dust in the cotton from being continuously under negative pressure when the negative pressure fan 6 pumps air outwards. Accumulated in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com