Degenerate pseudo-random rotary sensor

A rotary sensor and pseudo-random technology, applied in the direction of converting sensor output, using optical devices to transmit sensing components, instruments, etc., can solve the problems of circuit reliability decline, limited promotion, and complex discrimination circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

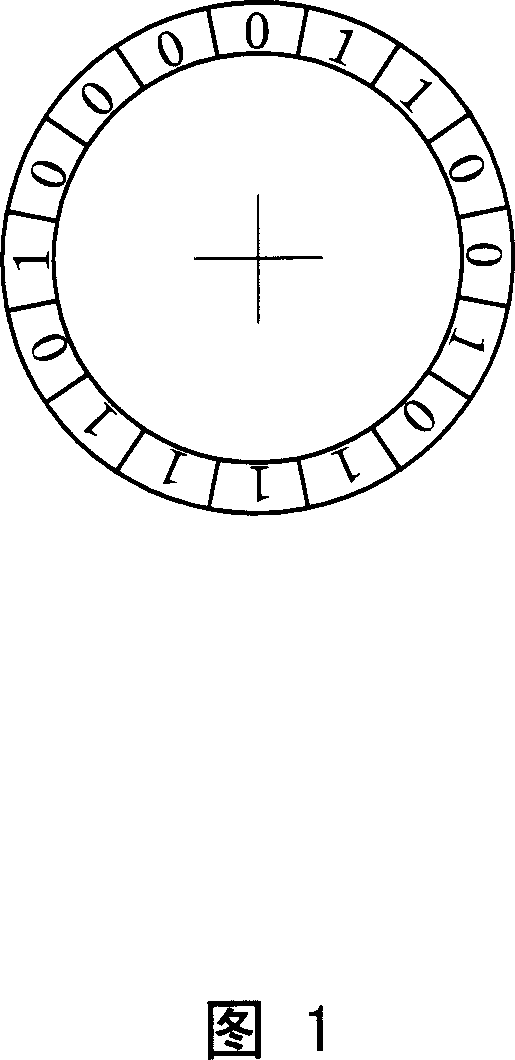

[0044] Embodiment 1: A degenerated pseudo-random rotation sensor is composed of two parts: an optical-mechanical structure and a circuit.

[0045] As shown in Figure 6, the optomechanical structure of this embodiment is composed of a printed board 1 with a photodetector, a code disc 2, an indicating grating 3, a condenser lens 4, a light source 5, a bearing 6, and a main shaft 7. The connection relationship is as follows: The main shaft 7 is located on the rotation axis of the code wheel 2 and is fixedly connected with the code wheel 2 . The main shaft 7 is rotatably supported by the bearing 6 . The light source 5 , the condenser lens 4 , and the indicating grating 3 form a projected light path on the front of the code wheel 2 relative to the code track. The printed board 1 with a photodetector is located on the opposite side of the code disc 2, and its photodetector is facing the projection light path. When the shaft 7 drives the code disc 2 to rotate, under the action of th...

Embodiment 2

[0059] Embodiment 2: A degenerate pseudo-random rotation sensor, which consists of two parts: an optical-mechanical structure and a circuit.

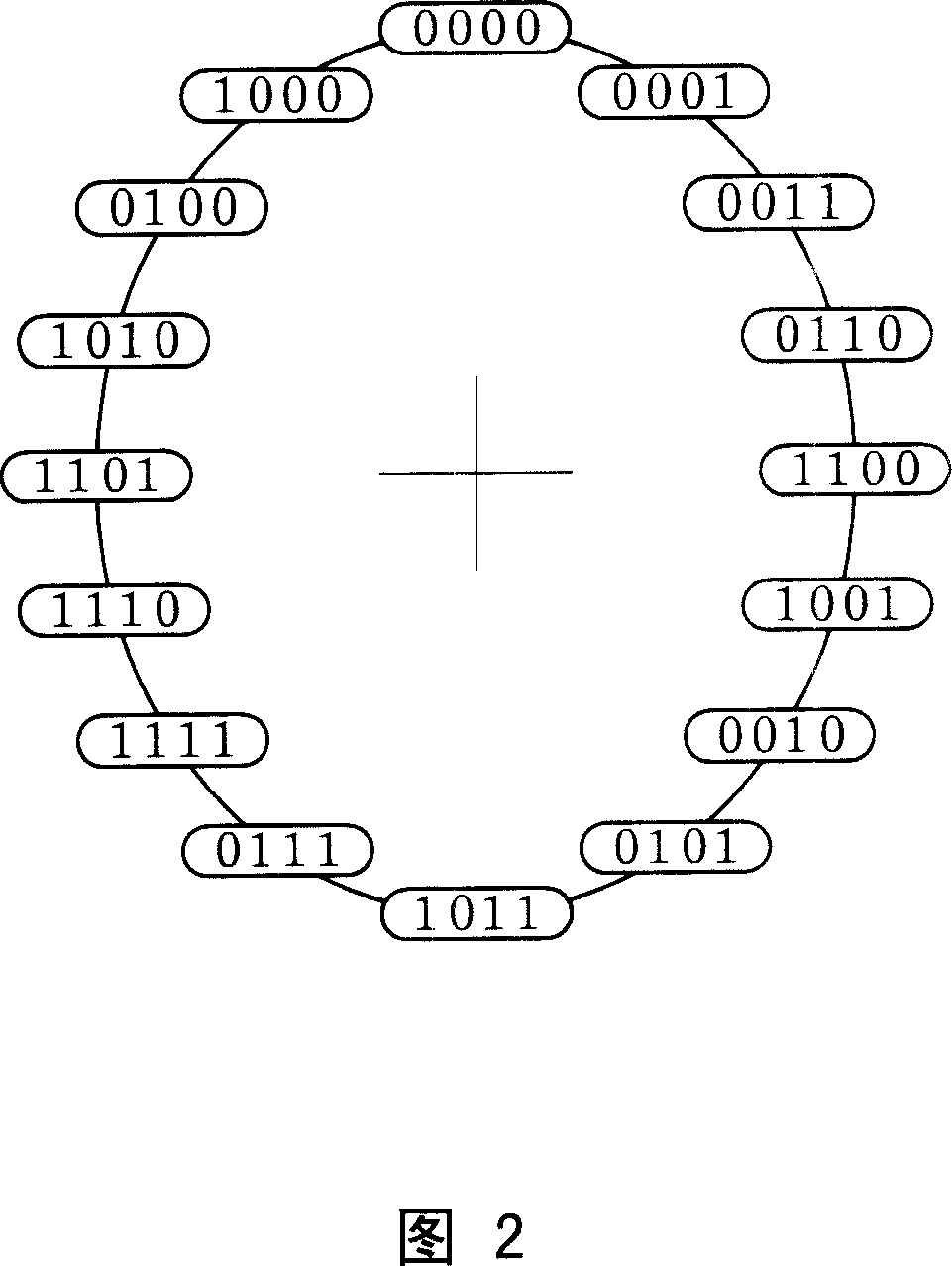

[0060] The main difference from the first embodiment is that the encoding of the pseudo-code channel adopts a seven-bit binary degenerate pseudo-random sequence. Specifically:

[0061] Seven complete binary pseudo-random sequence M=2 7 =128

[0062] 0 111 1 111 0111 1100 1111 0101 1110 0011 1011 0111 0100 1110 0101 11000011 0110 0110 1010 1101 0001 1001 0011 0001 0110 0000 1010 1001 0100 00 10 0100 0100 00 00

[0063] The amount of degradation is 28, m=100

[0064] The underlined 28-bit code in the above-mentioned seven-bit complete binary pseudo-random code sequence is discarded, and the seven-bit degenerated binary pseudo-random code sequence with a degradation amount of 28 is obtained as follows:

[0065] 1111 0101 1110 0011 1011 0111 0100 1110 0101 1100 0011 0110 0110 10101101 0001 1001 0011 0001 0110 0000 1010 1001 01...

Embodiment 3

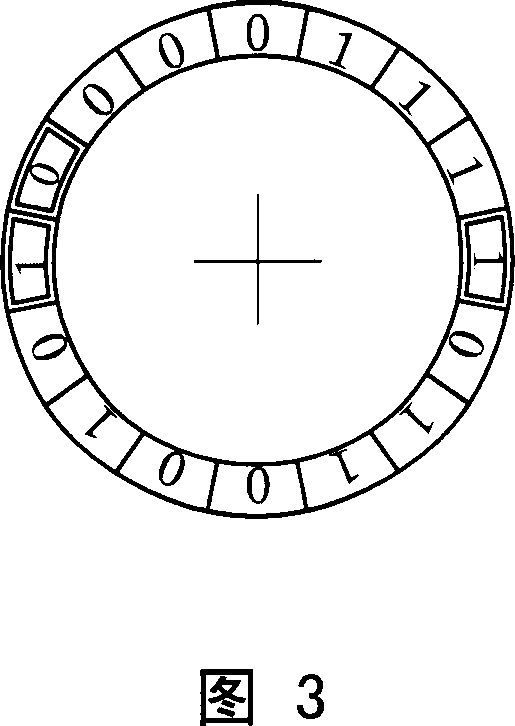

[0068] Embodiment 3: A degenerate pseudo-random rotation sensor, which consists of two parts: an optical-mechanical structure and a circuit.

[0069] The main difference from the first embodiment is that the encoding of the pseudo-code channel adopts an eight-bit binary degenerate pseudo-random sequence. Specifically:

[0070] Eight-bit complete binary pseudo-random sequence M=2 8 =256

[0071] 0 111 1011 0111 1010 0111 1001 0111 1000 0111 0111 0110 0111 0101 01110100 0111 1111 1 011 1111 0011 1110 1011 1110 0011 1001 1011 1001 0011 10001011 1000 0011 0110 1011 0110 0011 0101 0011 0100 1011 0100 0011 00 1 0010 1011 0010 0011 0001 0011 0000 1011 0000 0010 0101 0010 0100 00100010 1010 1000 1000 0010 1000 0000

[0072] The amount of degradation is 6, m=250

[0073] The underlined 6-bit code in the above-mentioned eight-bit complete binary pseudo-random code sequence is discarded, and the eight-bit degenerated binary pseudo-random code sequence with a degradation amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com