Wedging floor structure and assembling method

A slot-type, floor technology, which is applied in building structures, floors, buildings, etc., can solve the problems of solid wood floors that cannot be used for a second time, cannot be repaired and replaced a single piece, and troublesome in processing and installation. Significant economic benefits, simple structure, easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

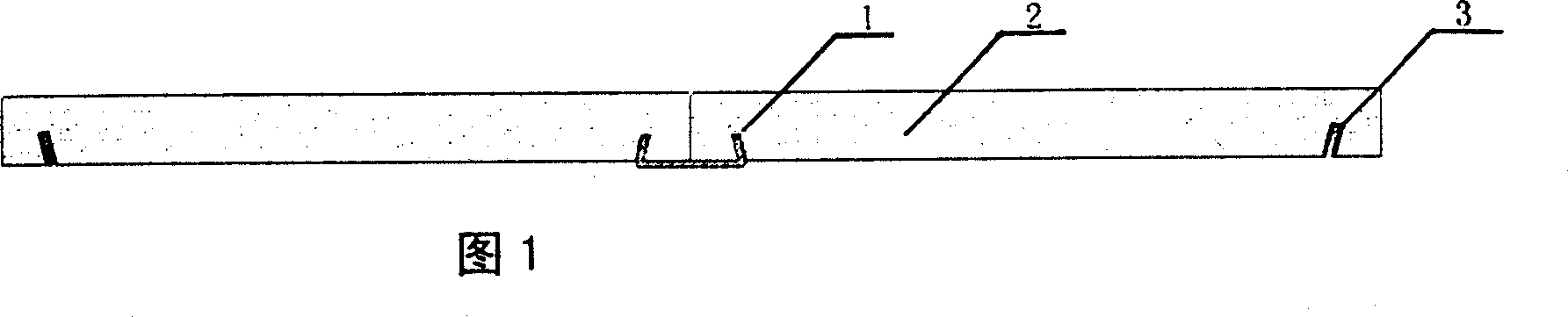

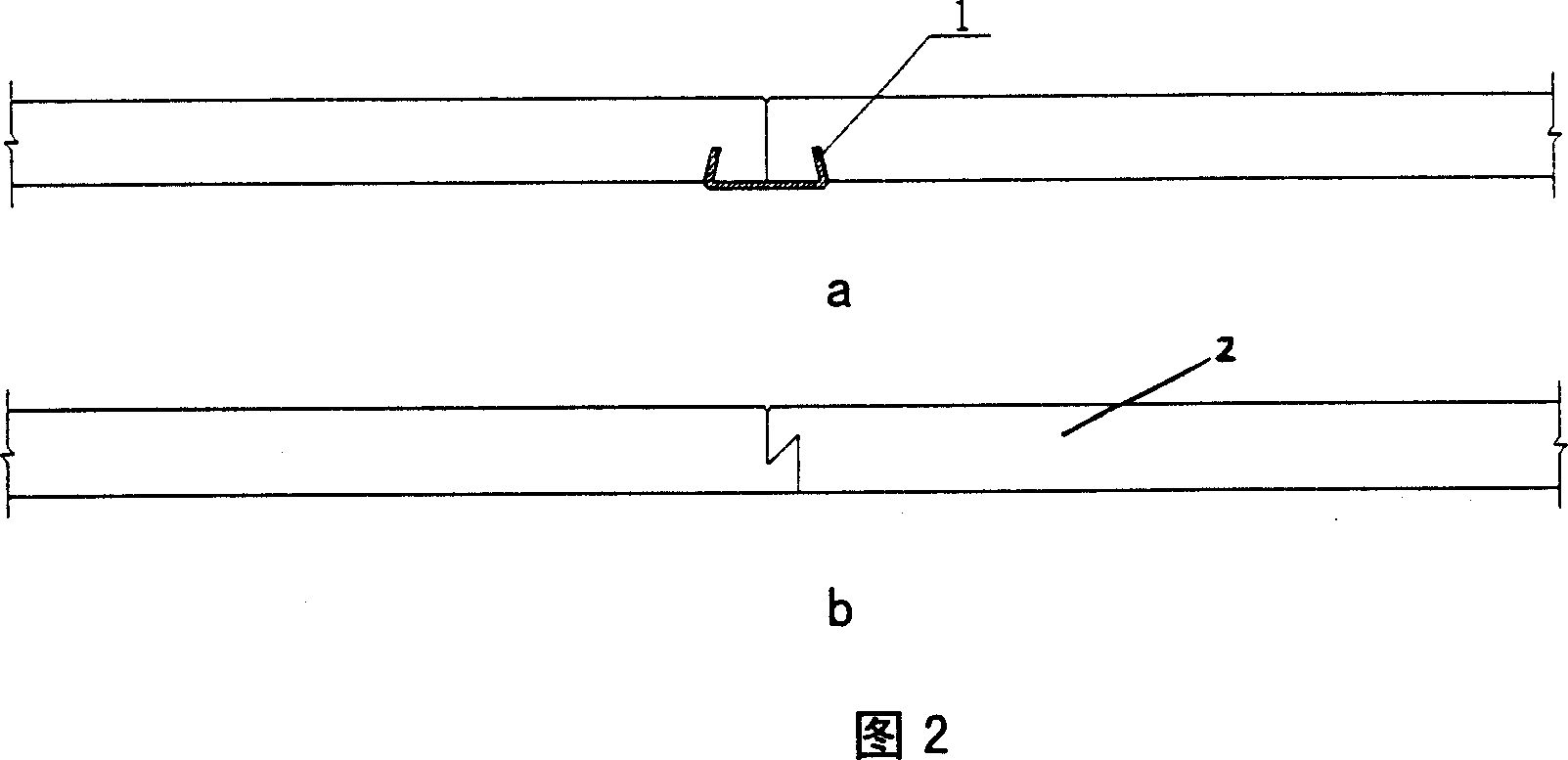

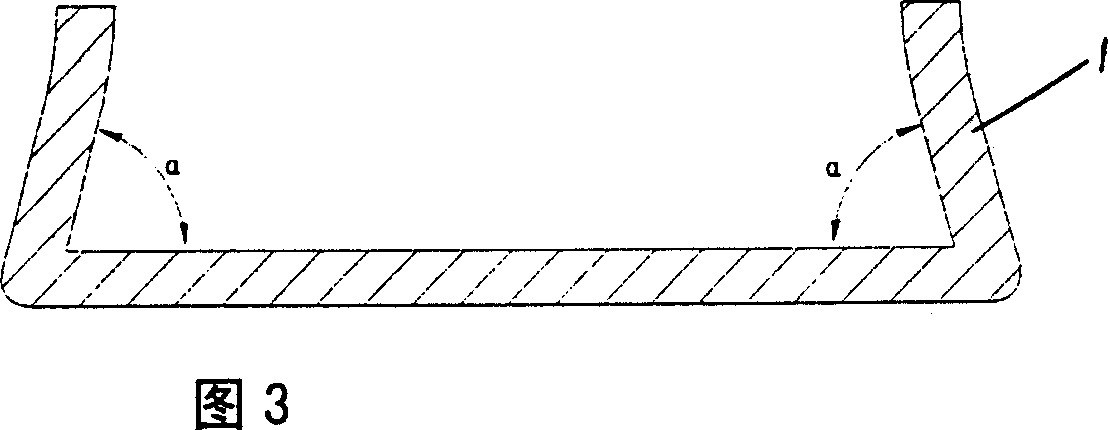

[0017] Embodiment 1, install with solid paving method. Before paving, the ground should be leveled, and a layer of foam cushions should be laid, and then two card-groove floors are connected by connector 1 to make width; the card-groove floor The two ends are extended with connector 1. Use this method to build up the width and length of the floor piece by piece to complete the installation of the floor.

Embodiment 2

[0018] Example 2, installation by overhead laying method, the ground should be leveled before paving, wooden keel is installed, a layer of foam cushion is laid, the connecting piece 1 is fixed on the wooden keel with self-tapping screws, and then the two clips The trough floor is clamped on the connecting piece 1 respectively. The two ends of the two card-groove floors are lapped in a 1 / 2 horizontal Z-shape or connected by connectors. Use this method to build up the width and length of the floor piece by piece to complete the installation of the floor.

[0019] The present invention can be used for solid wood floor, reinforced composite floor and solid wood composite floor, and its installation mode can be divided into two kinds of solid paving type and overhead paving type. The solid paving type is that the width and length of two floors are connected through the slotted joints; the overhead laying is that the joints are first fixed on the floor wood joists (or ground joists...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com