Automatic foam eliminating machine

An automatic and mechanical device technology, applied in the direction of biochemical instruments, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problems of no automatic control system, long foam swallowing time, environmental pollution, etc., to improve environmental protection Benefits, harm reduction, emission reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, which will be more detailed.

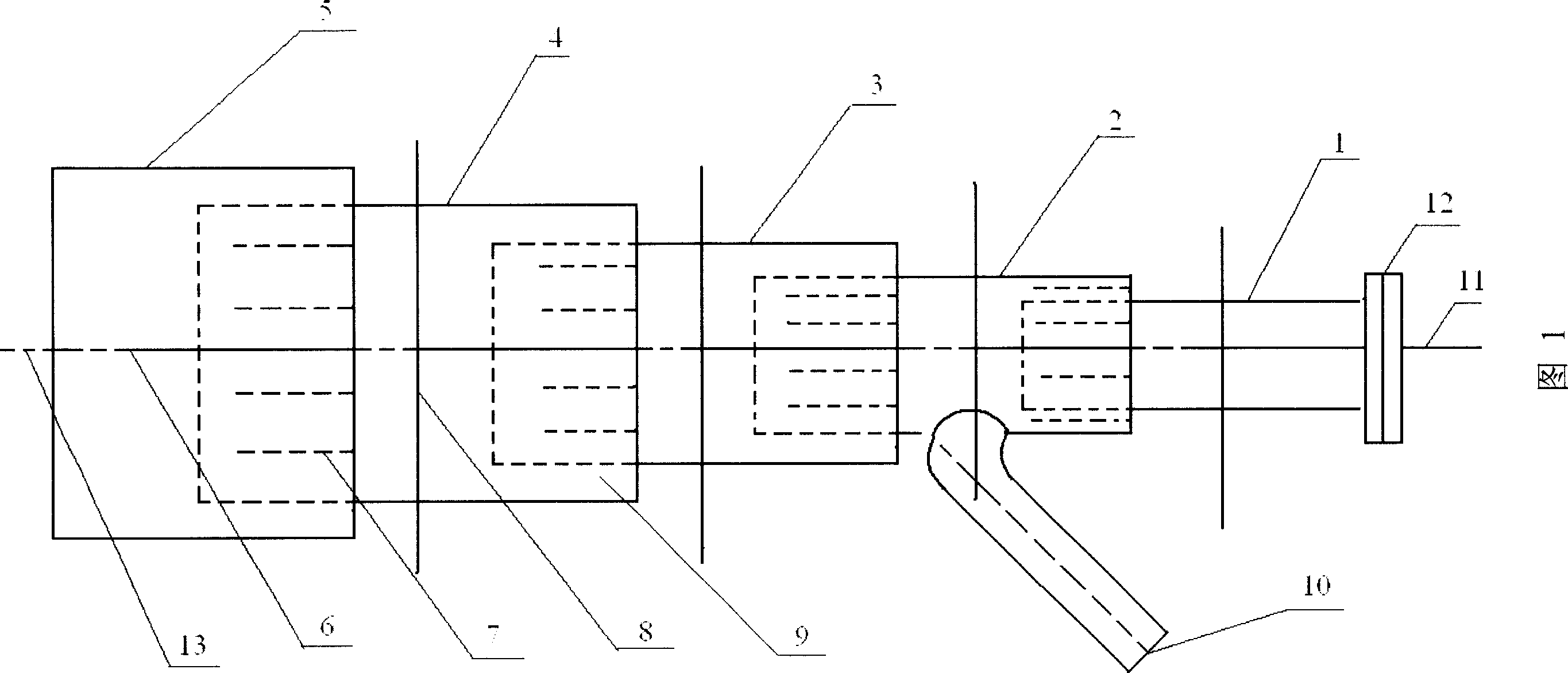

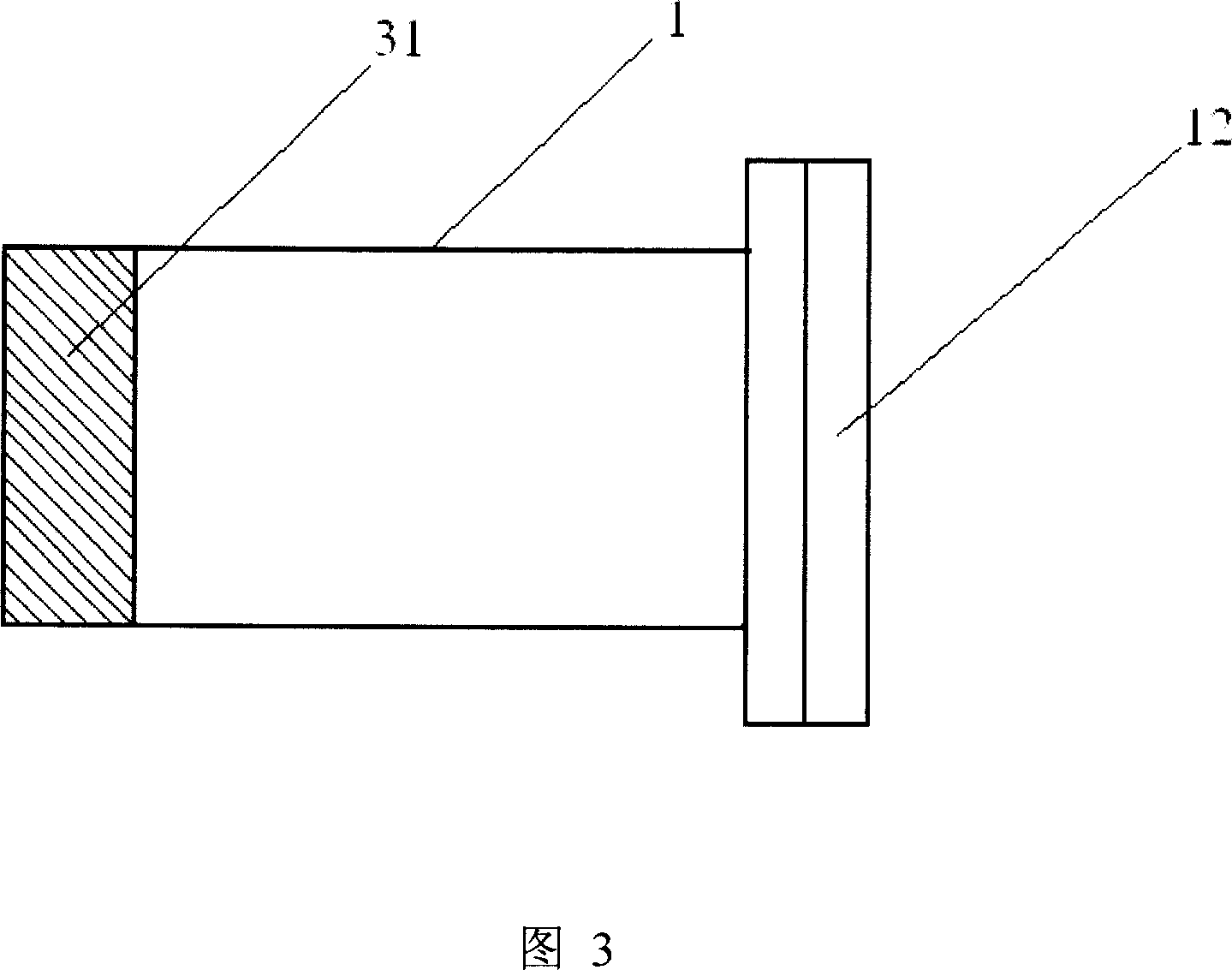

[0042] As shown in Figures 1 and 3, the present invention includes a mechanical device and an automatic control system. In the mechanical device, the nozzle 1 is connected to the nozzle 2, the nozzle 2 is connected to the nozzle 3, and the nozzle 3 is connected to the nozzle 4. The nozzle 4 connects to the nozzle 5. The five nozzles have different diameters and are connected to each other to form a trumpet-shaped spray chamber from thin to thick. At one end of the trumpet-shaped spray chamber, there is a constant velocity nozzle 1 inside the nozzle 1. The spiral device 31; the spray chamber 7 is connected to the machine as a whole; this mechanical device is also provided with a rear pipe 9 and an outer shell 10, wherein the rear suction pipe 9 plays the role of balancing the air flow, and the outer edge 10 It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com