Production process of twice grained cloth

A manufacturing method and secondary pressing technology, applied to flat products, applications, household appliances, etc., can solve the problems of discontinuous strength of embossed plastic cloth, blurred and uneven three-dimensional embossing, and achieve uniform and stable structural strength , Surface embossed three-dimensional clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

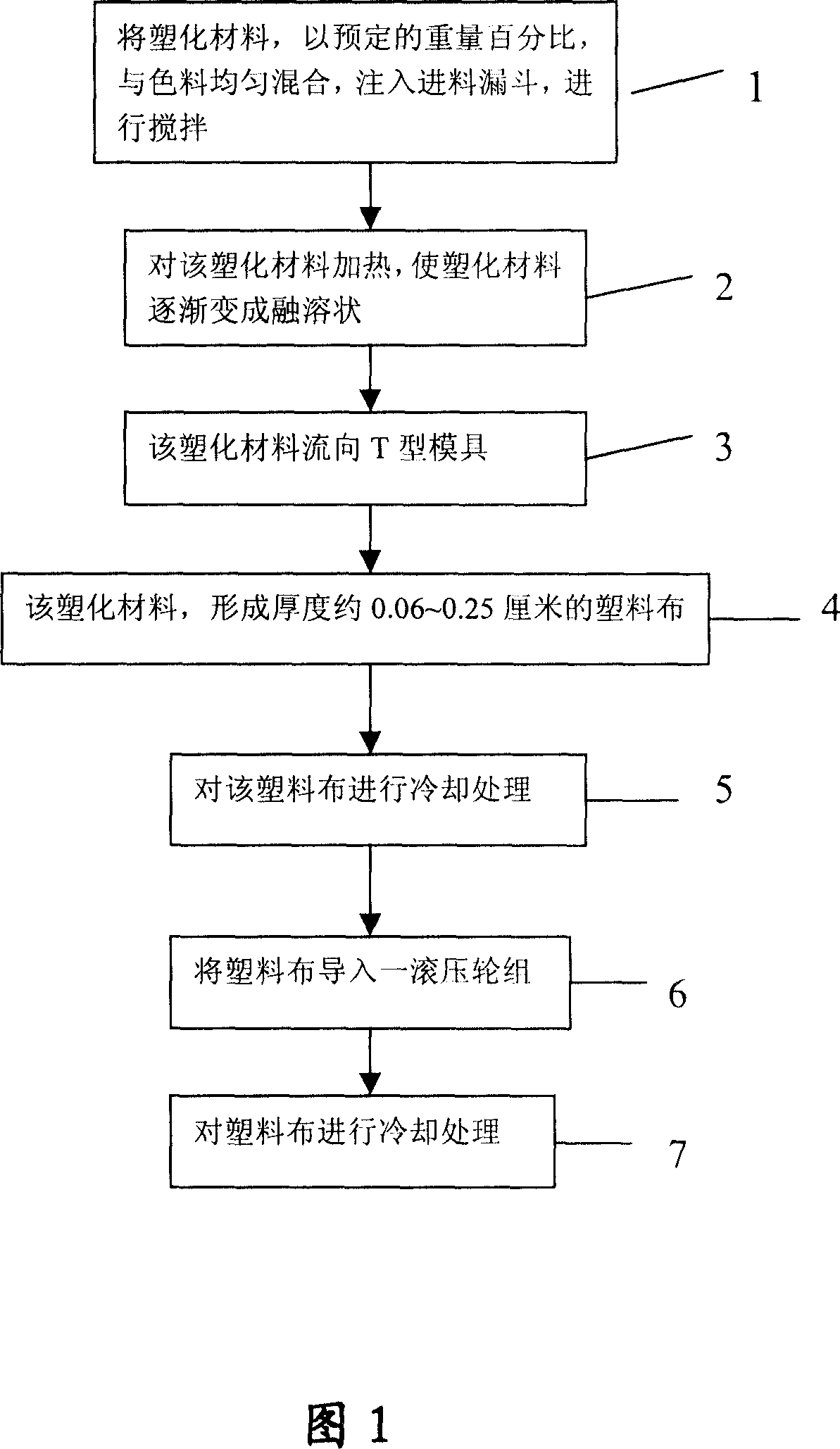

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings, but the implementation scope of the present invention is not limited.

[0015] The invention relates to a method for manufacturing environmentally friendly PE, EVA, and PEVA secondary embossed cloths. In the method, plastic granules (or powder) and colorants of polyolefin plasticized materials are injected into a feeding funnel, and After being stirred evenly by a stirrer in the hopper, it is introduced into an extruding sleeve equipped with a heating element outside, and the plasticized material is heated by the heating element in the extruding sleeve to gradually form a molten state, Driven by an extruding screw provided in the extruding sleeve, it flows to a T-shaped die provided at the other end of the extruding sleeve, and through this T-shaped die, a flat plastic cloth (or plastic film), and then the plastic cloth is cooled, and then the plastic cloth is introduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com