High speed roller pressing forming machine

A technology of forming machine and high-speed roller, applied to forming tools, feeding devices, positioning devices, etc., can solve the problems of low production efficiency, unstable work, poor quality of the board surface, etc., achieve uniform spraying, convenient control, and prevent splashing with outflow effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

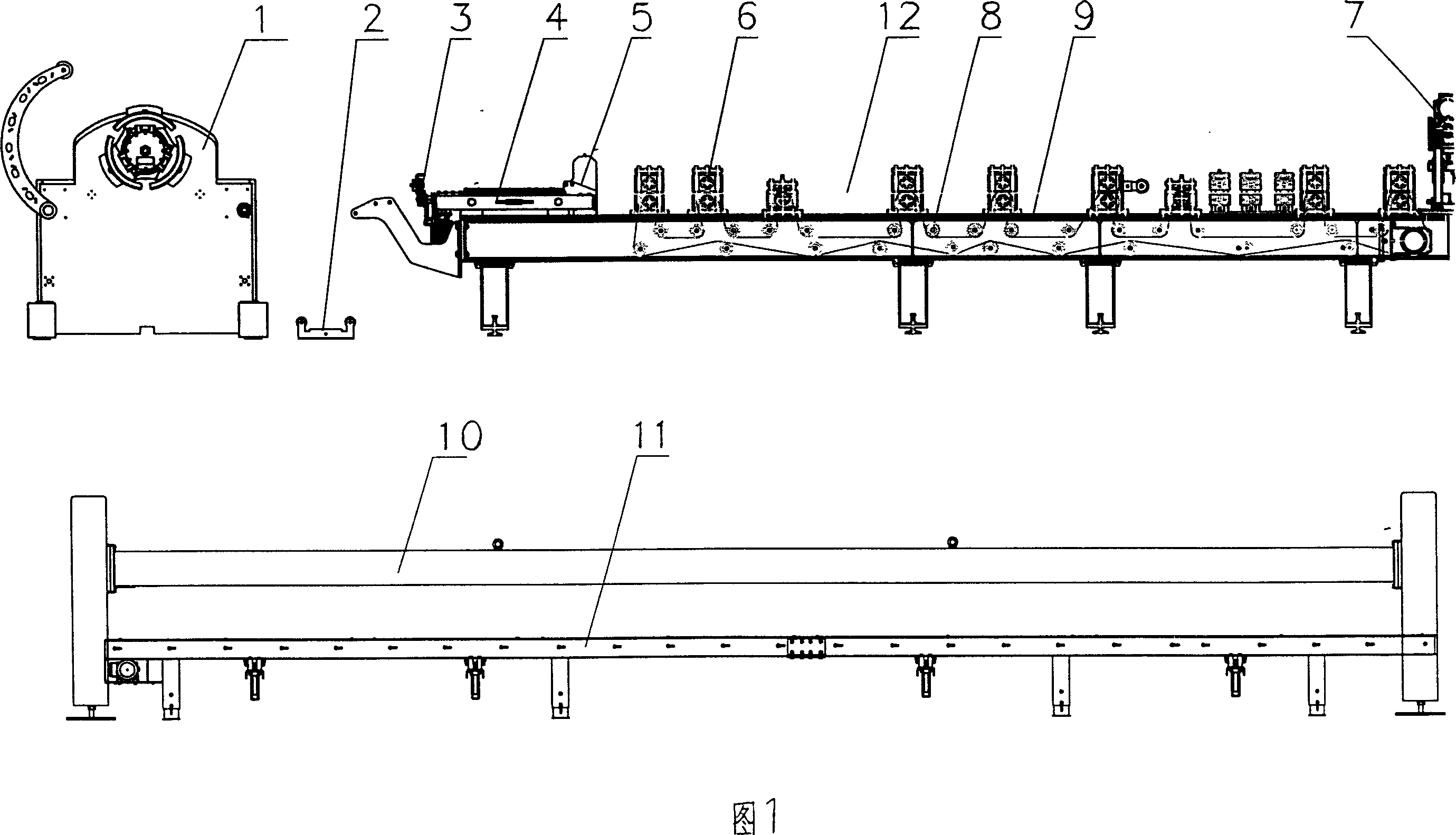

[0034] The present invention mainly consists of a frame 9 with a drive mechanism 8, an ultrasonic device 2 and an active uncoiler 1 placed in the front of the frame 9, and a front cutting device 3 and a front guide device 4 placed on the frame 9 from front to back. , The lubrication device 5, the roller press unit 6 connected with the transmission mechanism 8, the rear cutting device 7, the palletizing device 10 placed at the rear of the frame 9 and the roller conveyor 11 below the palletizing device 10, etc.

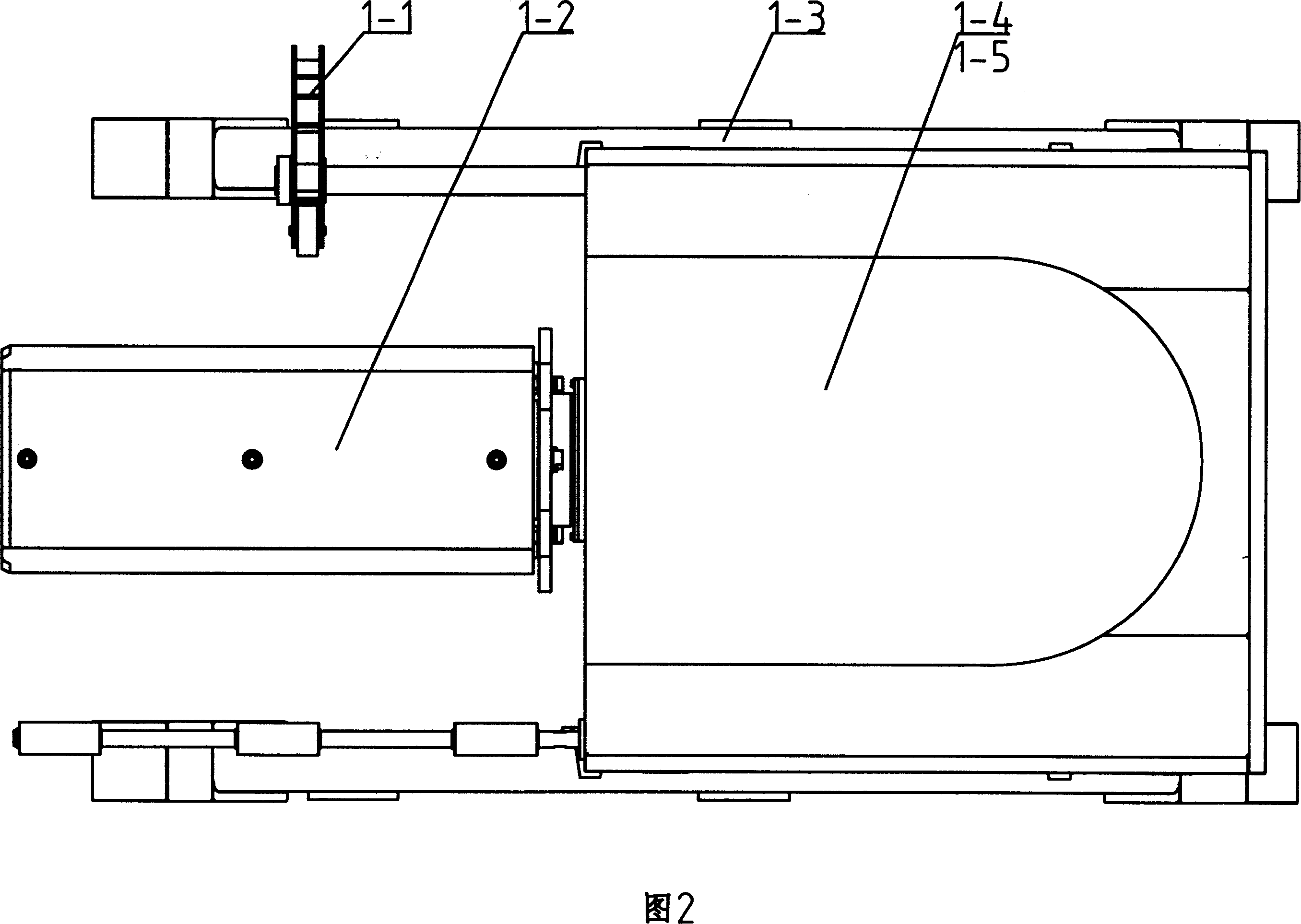

[0035] The active uncoiler 1 is composed of a material pressing arm 1-1 placed on a loading frame seat 1-3, an expansion device 1-2, a safety cover 1-4 with a transmission component 1-5 inside, and the like.

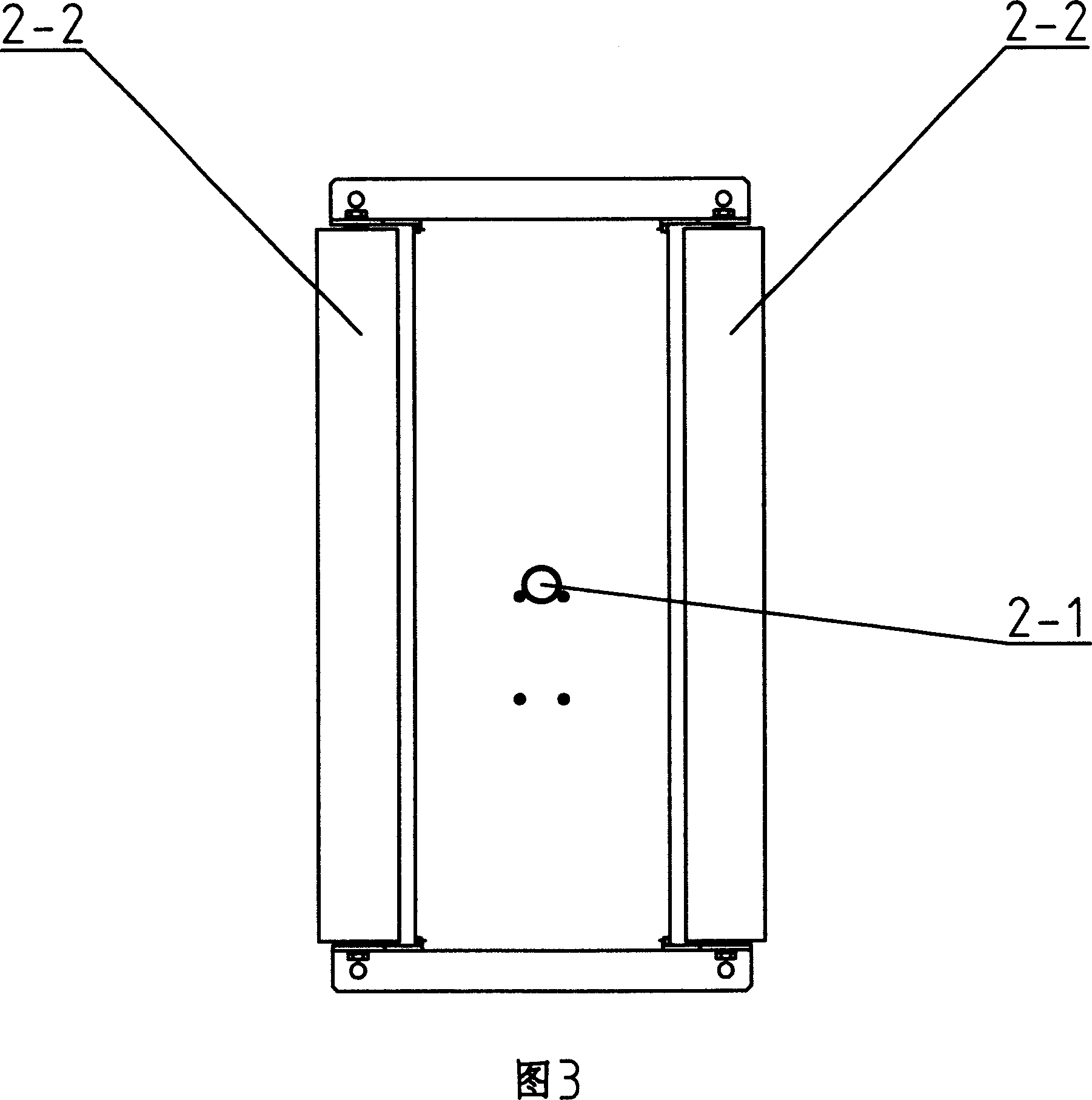

[0036] The ultrasonic device 2 is composed of an ultrasonic sensor 2-1, a roller 2-2, and the like.

[0037] The front cutting device 3 is fixed on the frame 9 by a fixing frame 3-6 with a cutting motor 3-1 and a sprocket 3-4, and is placed between the sprocket 3-4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com