Gravel separating and drying device

A drying device and sand and gravel separation technology, applied in the directions of drying gas arrangement, solid separation, drying, etc., can solve the problems of difficult separation and low drying efficiency, save time, improve drying efficiency, and avoid frequent cleaning of the device Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is further described in detail through specific implementation methods:

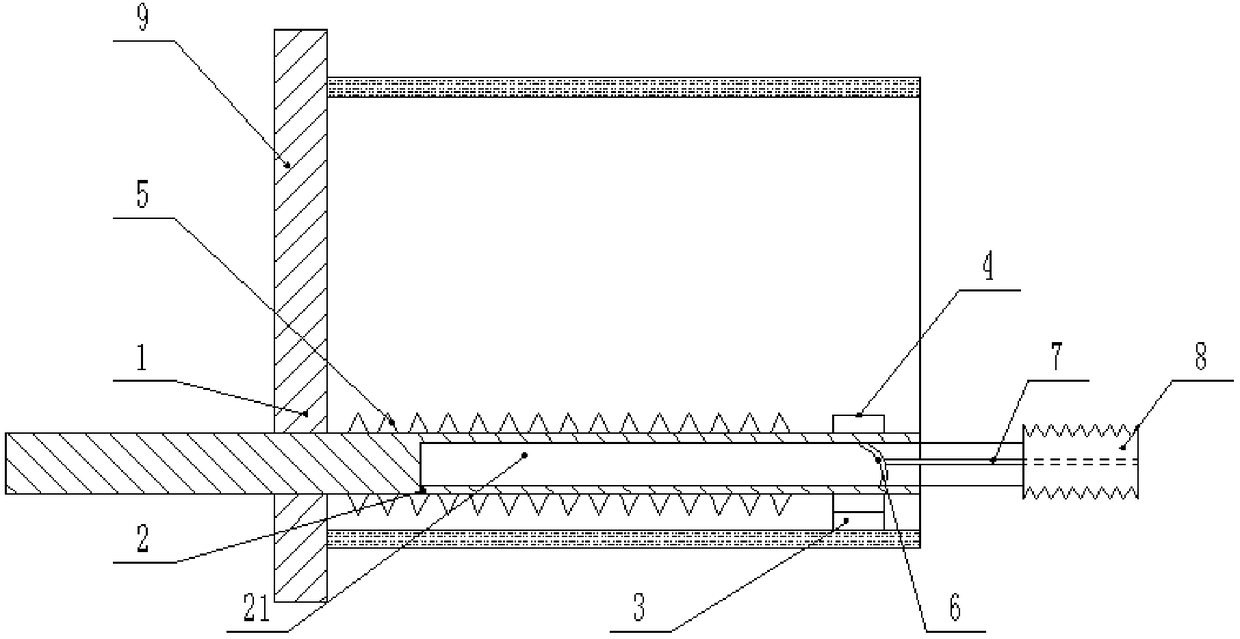

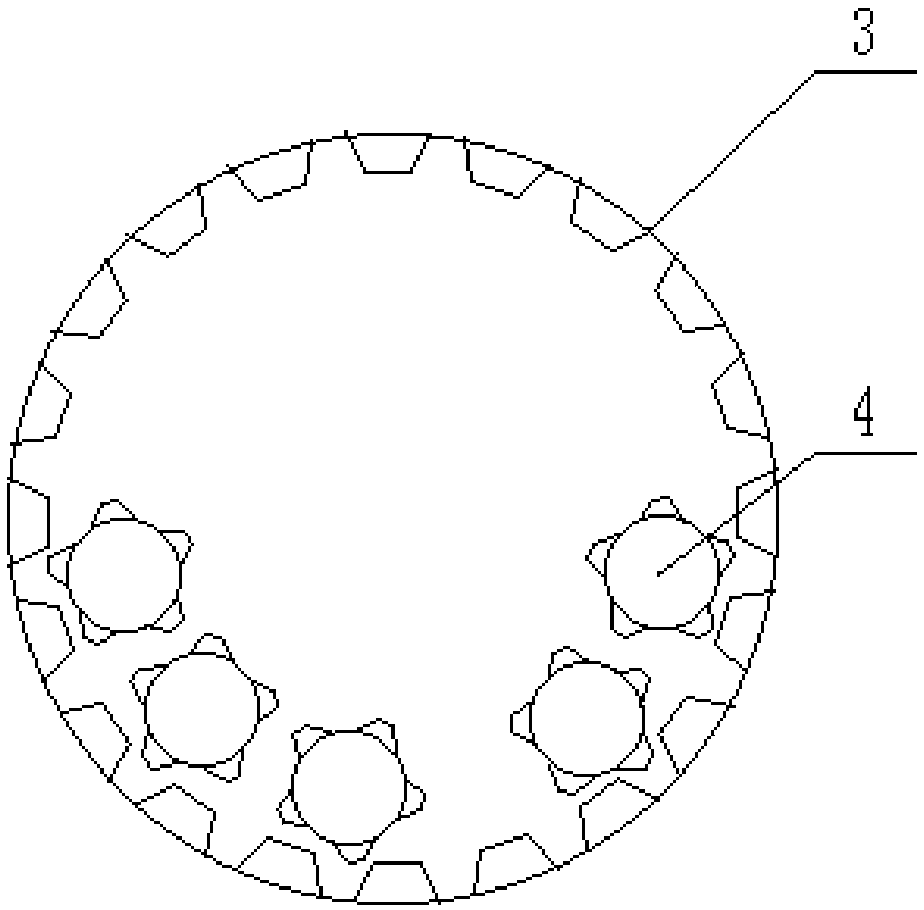

[0018] The reference signs in the accompanying drawings of the specification include: trommel 1, rotating roller 2, air intake groove 21, ring gear 3, gear 4, protrusion 5, spiral groove 6, mast 7, telescopic cover 8, bottom plate 9.

[0019] Such as figure 1 As shown, the sand and gravel separation and drying device includes a frame on which a rotating motor is fixed, and a trommel 1 is connected to rotate on the frame, and a belt for transmission is connected between the outer wall of the trommel 1 and the output shaft of the rotating motor; The left end of the sieve 1 is connected with a disc-shaped bottom plate 9, and the right end of the trommel 1 is connected with a cover plate, and the cover plate and the bottom plate 9 are fixed on the frame, such as figure 2 As shown, the lower side of the base plate 9 is provided with a plurality of through holes, and the connecting line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com