Contact image sensor and method for manufacturing the same

An image sensor, contact technology, applied in the direction of image communication, electrical components, etc., can solve problems such as uniformity, and achieve the effect of easy online adjustment and large amount of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

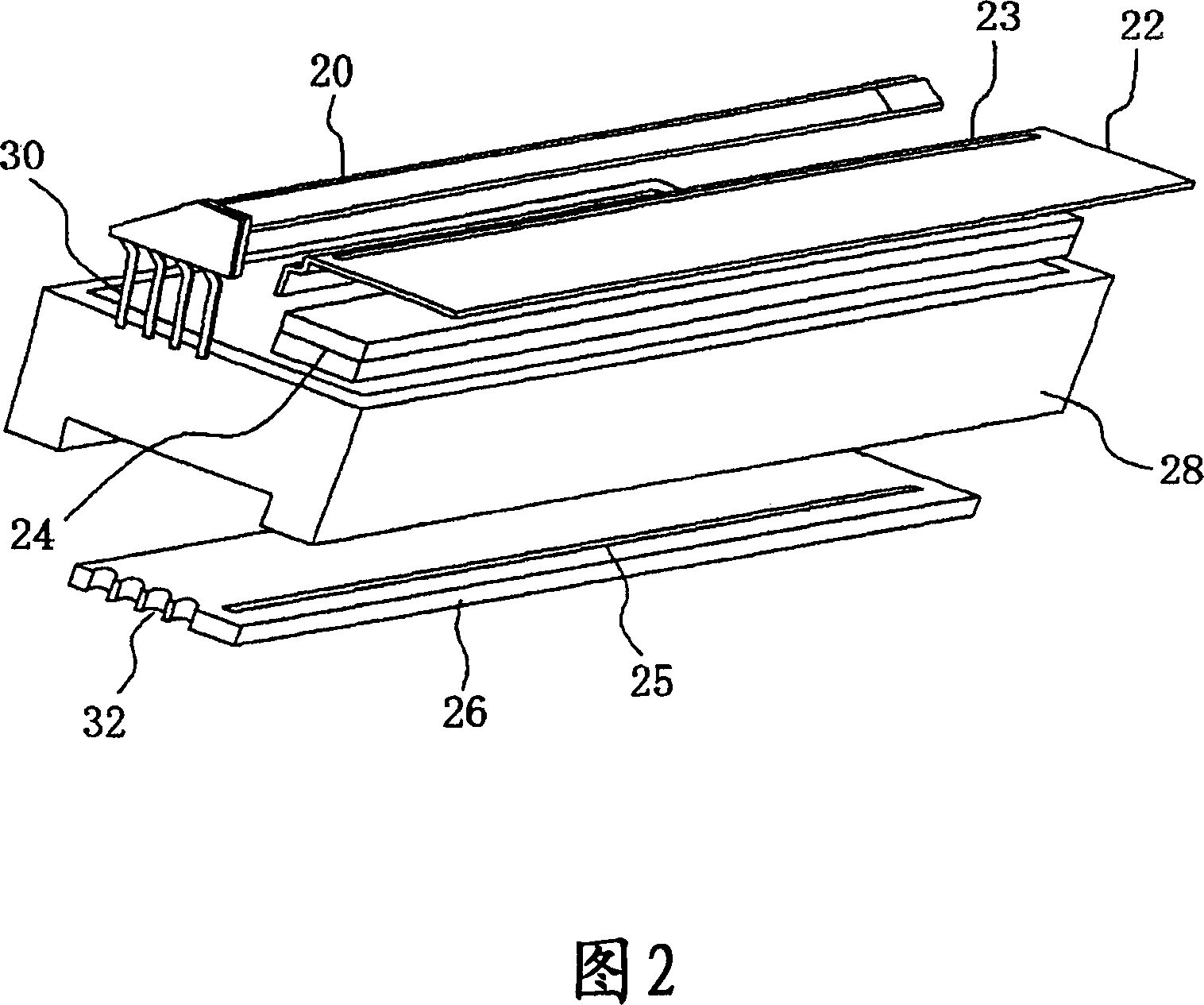

[0049] Fig. 2 is an exploded perspective view of a contact image sensor. This contact image sensor is made up of the following parts: light source 20, slit 22, the upright equal-magnification lens 24 that is made of overlapping two plate microlens arrays 24A and 24B, the light-receiving element array 25 that has installed light-receiving element array 24. The element array substrate 26, and the case 28 for accommodating the above-mentioned components.

[0050] The light source 20 is a linear lighting device, and as such a linear lighting device, there are those in which the array of light emitting elements extends in the main scanning direction, those in which light emitting elements are provided at the ends of the linear light guide, and the like.

[0051] In addition, in this embodiment, an example in which light-emitting elements composed of three light-emitting diodes (LEDs) of R color, G color, and B color are provided at the end of the linear light guide will be describe...

Embodiment 2

[0073] The contact image sensor of the second embodiment can be realized by the configuration shown in FIG. 2, and the description of the same constituent elements will be omitted. In Embodiment 2, a method of adjusting the position of the light-receiving element array substrate which is different from Embodiment 1 will be described. The method is as follows: firstly, the light-receiving element array receives the reflected light of a reference original (such as a white original) with uniform brightness distribution corresponding to the light distribution in the main scanning direction of the light source, and then detects the sensor corresponding to the light distribution in the main scanning direction of the light source. output. Next, in order to reduce the detected difference in sensor output in the main scanning direction, the position of the light receiving element array substrate is adjusted by inclining the position of the light receiving element array in the sub scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com