Novel even-tension high-speed needling machine

An acupuncture and tension technology, which is applied in the directions of acupuncture, textiles, papermaking, non-woven fabrics, etc., can solve the problems that the angle sensor cannot receive signals in time, and the working accuracy of the angle sensor is affected, and achieves simple structure and low manufacturing cost. , The effect of improving the surface quality of the fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

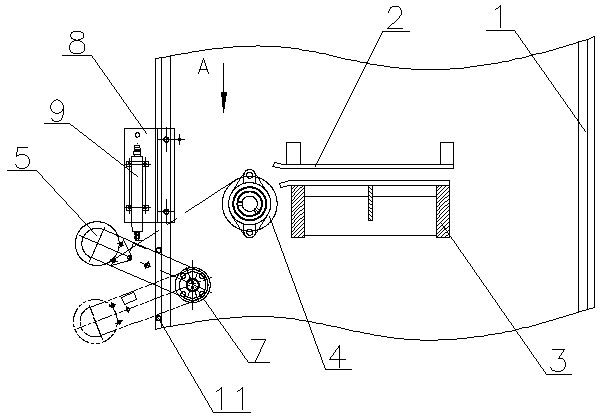

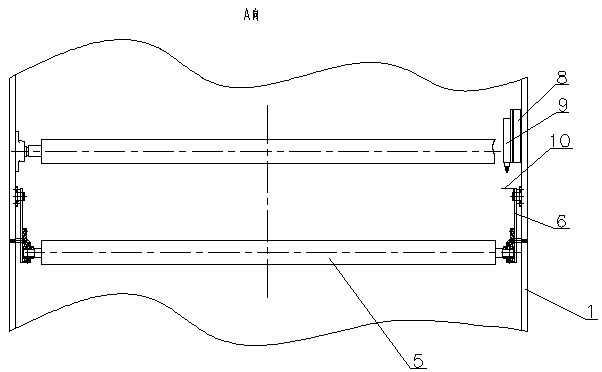

[0016] A new uniform tension high-speed needle punching machine, comprising a frame 1, the frame 1 is provided with a net stripping part 2 and a net support part 3, the net stripping part 2 is located directly above the net support part 3, the net stripping part 2 and the net support part 3 The front of the supporting net part 3 is provided with an input roller 4 installed on the frame 1, and the frame 1 is provided with a swing roller 5. Frame 1 is connected, and frame 1 side is provided with sensor support 8, and displacement sensor 9 is installed on sensor support 8, and support arm 6 below displacement sensor 9 is provided with connection plate 10, and connection plate 10 can touch when support arm 6 rotates. Touch the guide rod tail end of displacement sensor 9.

[0017] The lower end of the support arm 6 of the present invention is provided with a limit rod 11 installed on the frame 1 .

[0018] The tail end of the guide rod of the displacement sensor 9 of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com