A ramie conveying and stripping machine

An all-in-one machine and hemp stripper technology, which is applied in mechanical processing, fiber mechanical separation, textiles and papermaking, etc., can solve the problems of labor-intensive labor, inconvenient automation, large-scale feeding, and difficulty in ensuring synchronization, so as to reduce safety. The probability of accident occurrence, the convenience of fully automated operation, and the effect of reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

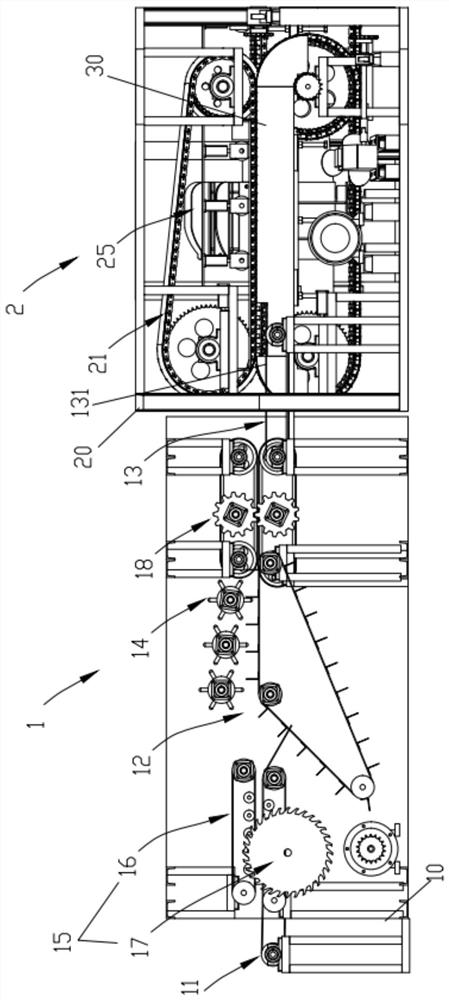

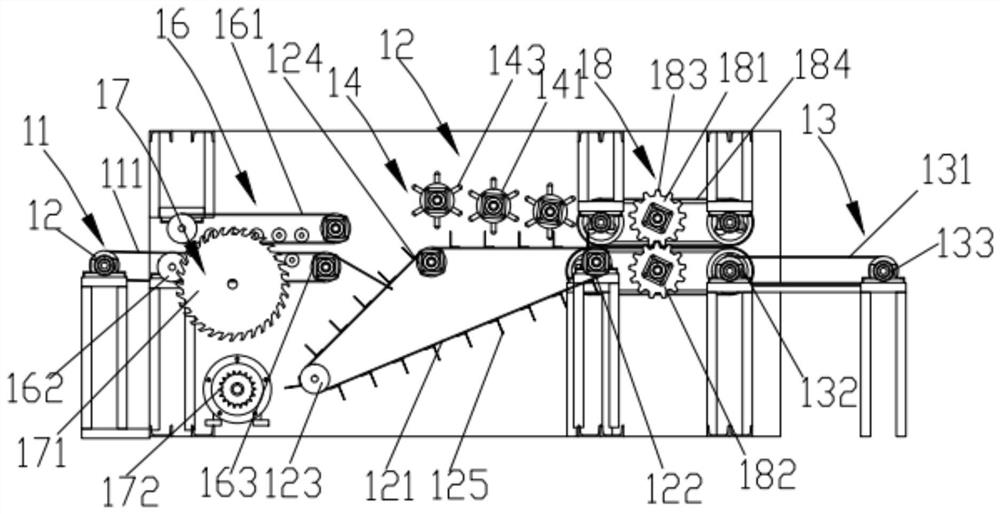

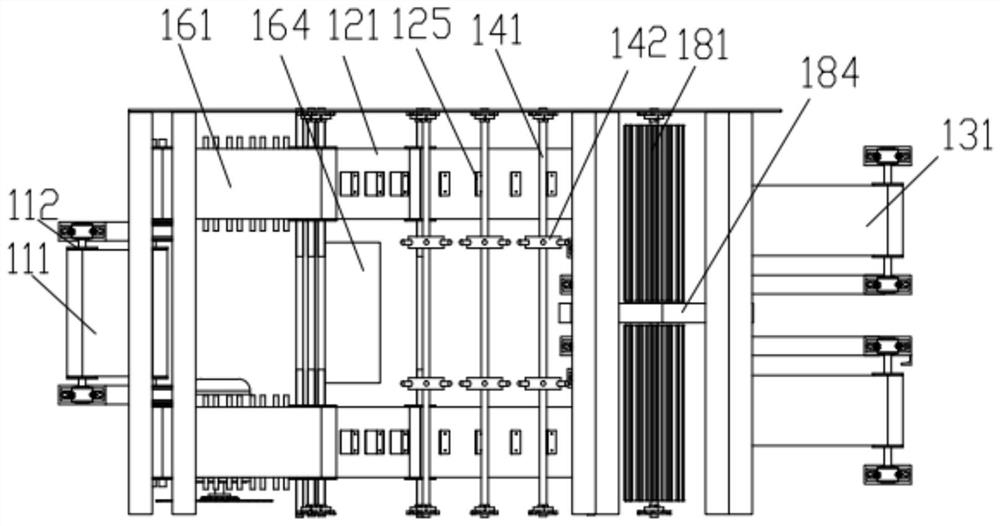

[0064] Such as Figure 1-6 As shown, the present invention discloses a ramie conveying and stripping integrated machine, including a ramie conveyor 1 and a ramie stripping machine 2, wherein the ramie conveyor 1 includes a conveyor frame 10 and an upper frame mounted on the conveyor frame 10 Material conveying device 11, hemp homogenizing device 12 and hemp feeding device 13, the hemp stripping machine 2 comprises the hemp stripping machine frame 20 and the ramie clamping conveying device 21 and the hemp stripping mechanism 25 installed on the hemp stripping machine frame 20, the upper The output end of the material delivery device 11 is connected with the input end of the hemp smoothing device 12, the output end of the hemp smoothing device 12 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com