Planetary gear torque converter

A technology of planetary gears and planetary gear trains, applied in gear transmissions, belts/chains/gears, mechanical equipment, etc., can solve problems such as high requirements, difficult processes, and limited torque range of hydraulic torque converters. Easy maintenance, high power transmission efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

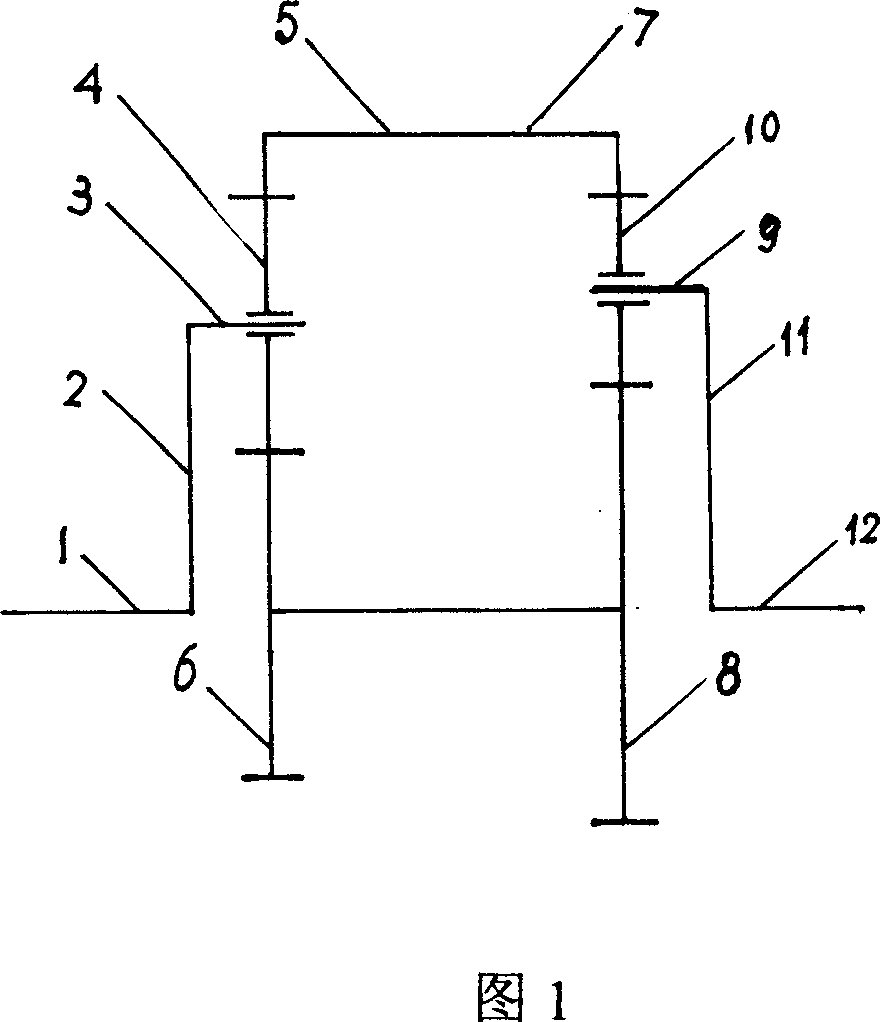

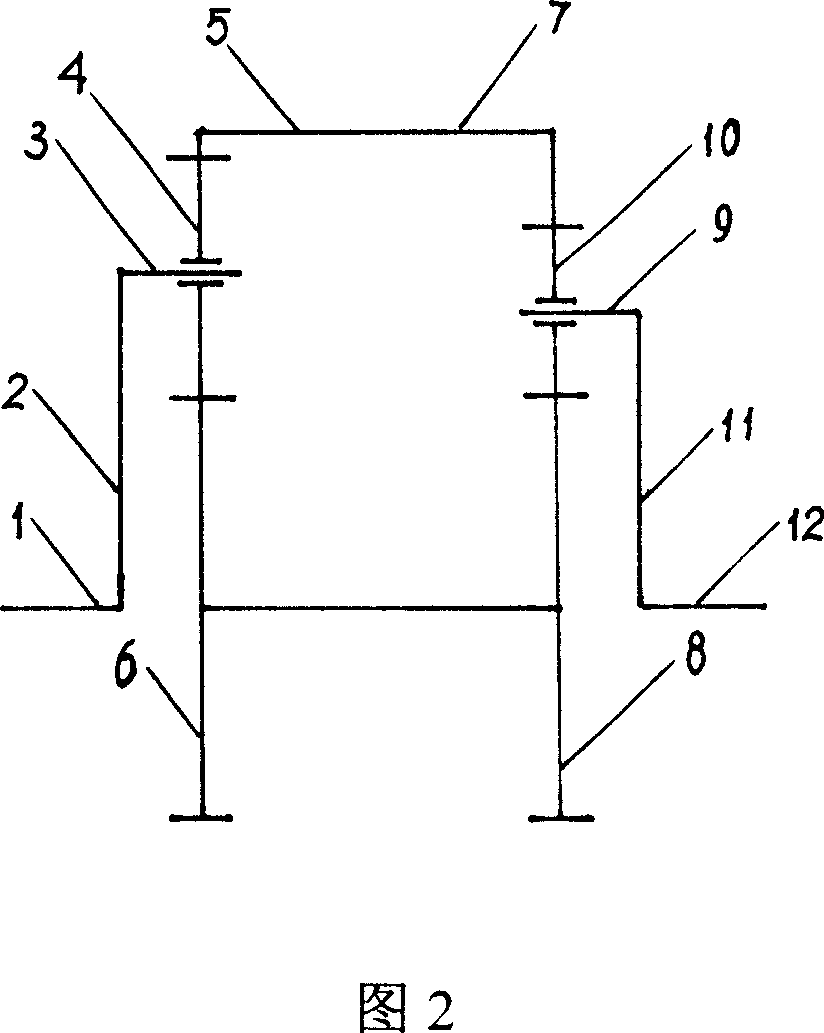

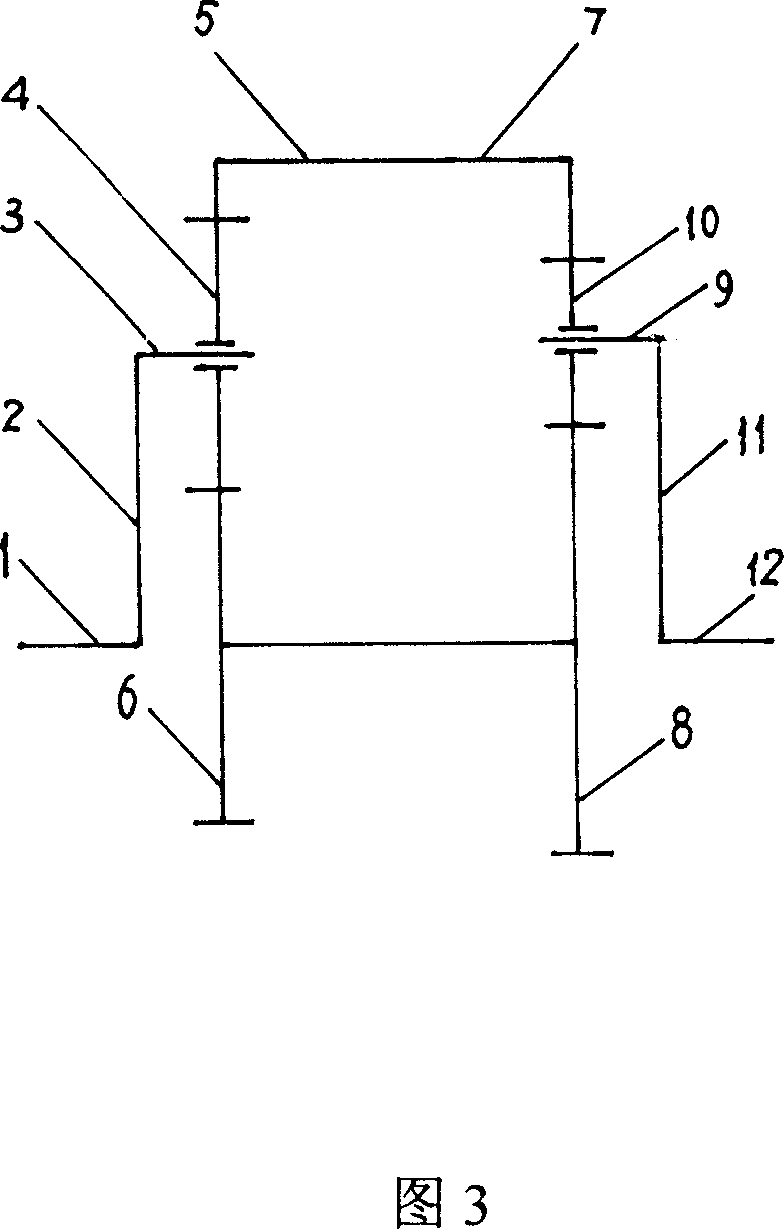

[0022] In the accompanying drawings, the star gear torque converter is composed of planetary gear input shaft 1, planet carrier 2, planetary shaft 3, planetary gear 4, internal gear 5, sun gear 6 in row A; planetary gear internal gear 7 in row B, sun gear 8, The planetary gear shaft 9, the planetary gear 10, the planetary carrier 11, the output shaft 12, and the locking clutch 13 constitute; the number of planetary gears is between 3-12; the gears can be straight teeth, helical teeth or herringbone teeth.

[0023] In Fig. 1, the input shaft 1 inputs torque, and the input force is transmitted to the internal gear 5 and the sun gear 6 through the planetary carrier 2, the planetary shaft 3, and the planetary gear 4, and is decomposed into two forces of equal magnitude, and the internal gear 5 is transmitted to the internal The force of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com