Oscillation suppression and control system for floating platform

A floating platform and oscillation frequency technology, applied in the direction of reducing ship motion through displacement, can solve problems such as reducing the effective bearing capacity of the platform system, the weight of the anchor bar system, and increasing the cost of the anchor bar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

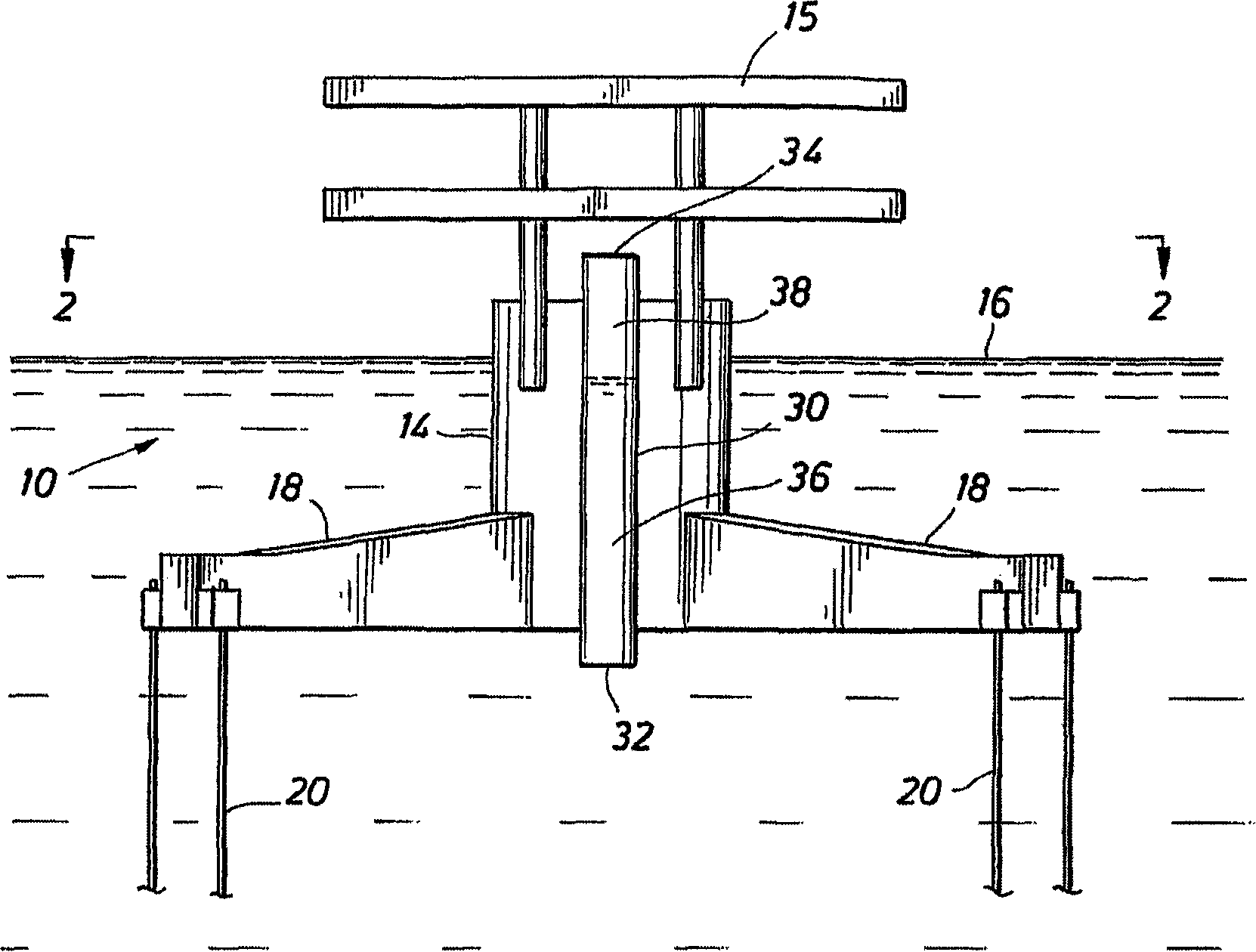

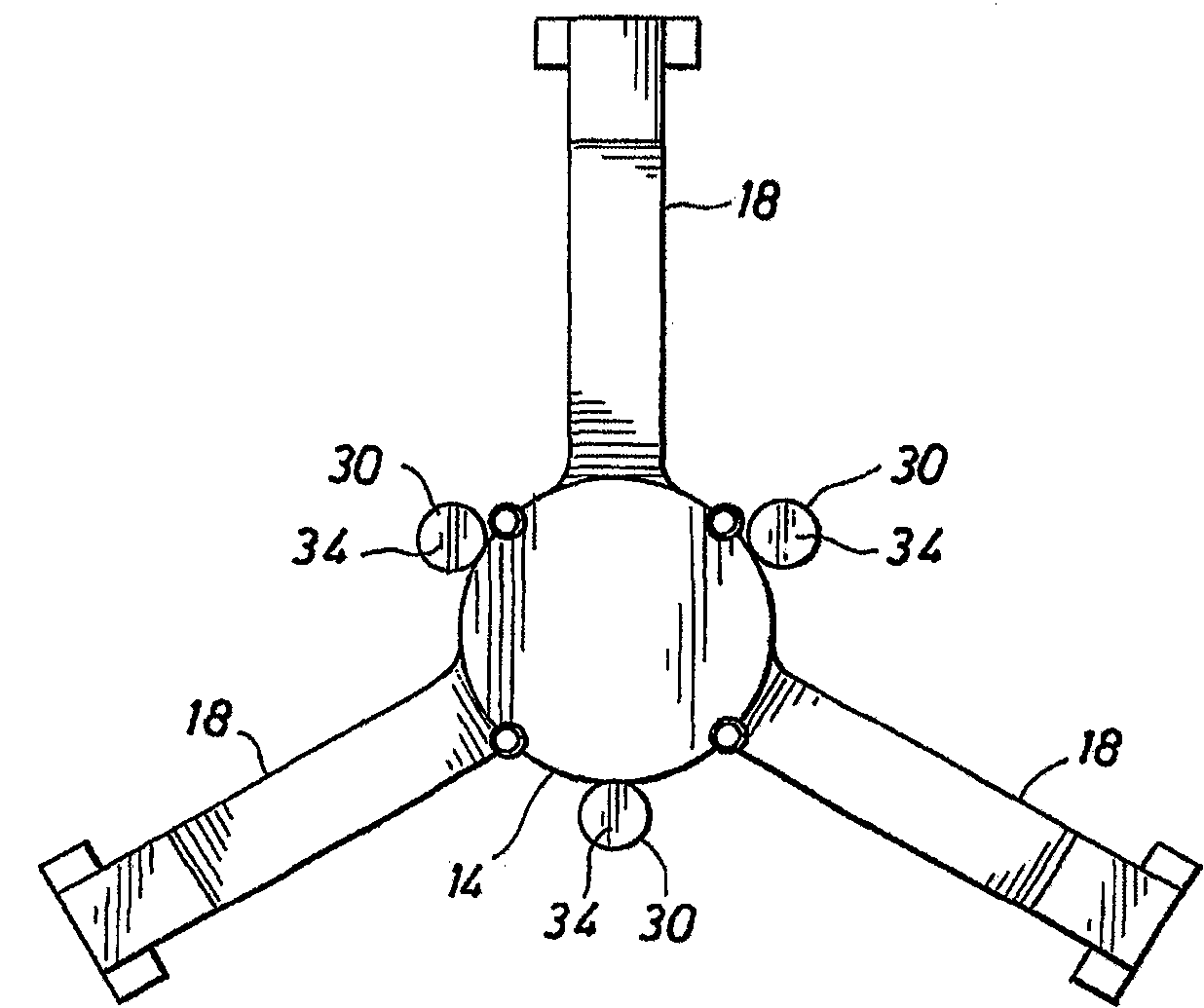

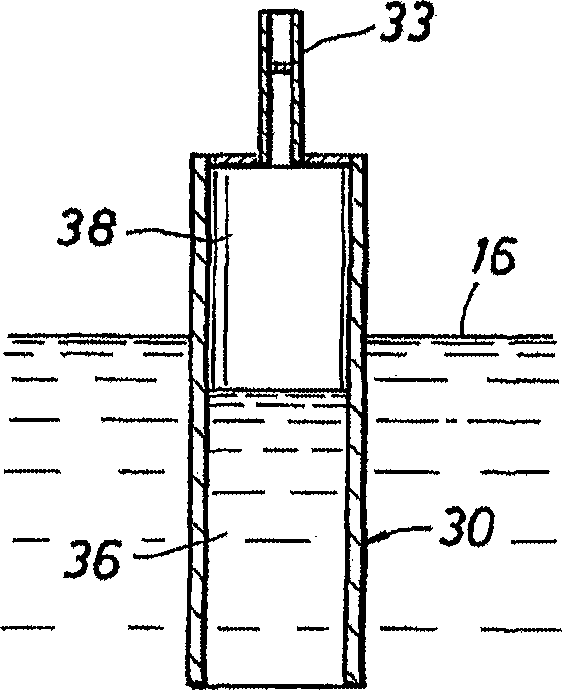

[0022] see now figure 1 , shown in the figure is a single-column shell-type floating platform generally indicated by reference number 10 . The floating platform 10 includes a column or hull member 14 projecting above the water surface 16 on which a platform deck 15 is supported. The float 18 extends radially outward from the base of the housing 14 . The floating platform 10 is anchored to the seabed by tendons.

[0023] In a typical anchor bar design, steel bars are used to secure the floating platform 10 to the seafloor. As the exploration and production of oil deposits extends into deeper waters, the design of the anchor bar system becomes more critical and begins to dominate the cost of the platform. The anchor tendon system must be designed to operate between allowable minimum and maximum tensions to dampen inherent resonant motion and limit fatigue damage from each stress cycle. The latter two are usually achieved by increasing the cross-sectional area of the bar, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com