Cast-cutting saw slice and manufacturing technique thereof

A technology for cutting saws and saw blades, applied in the field of cutting tools, can solve the problems of low speed, slow chip removal, not sharp enough, etc., and achieve the effects of high speed, reasonable process, and fast chip removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

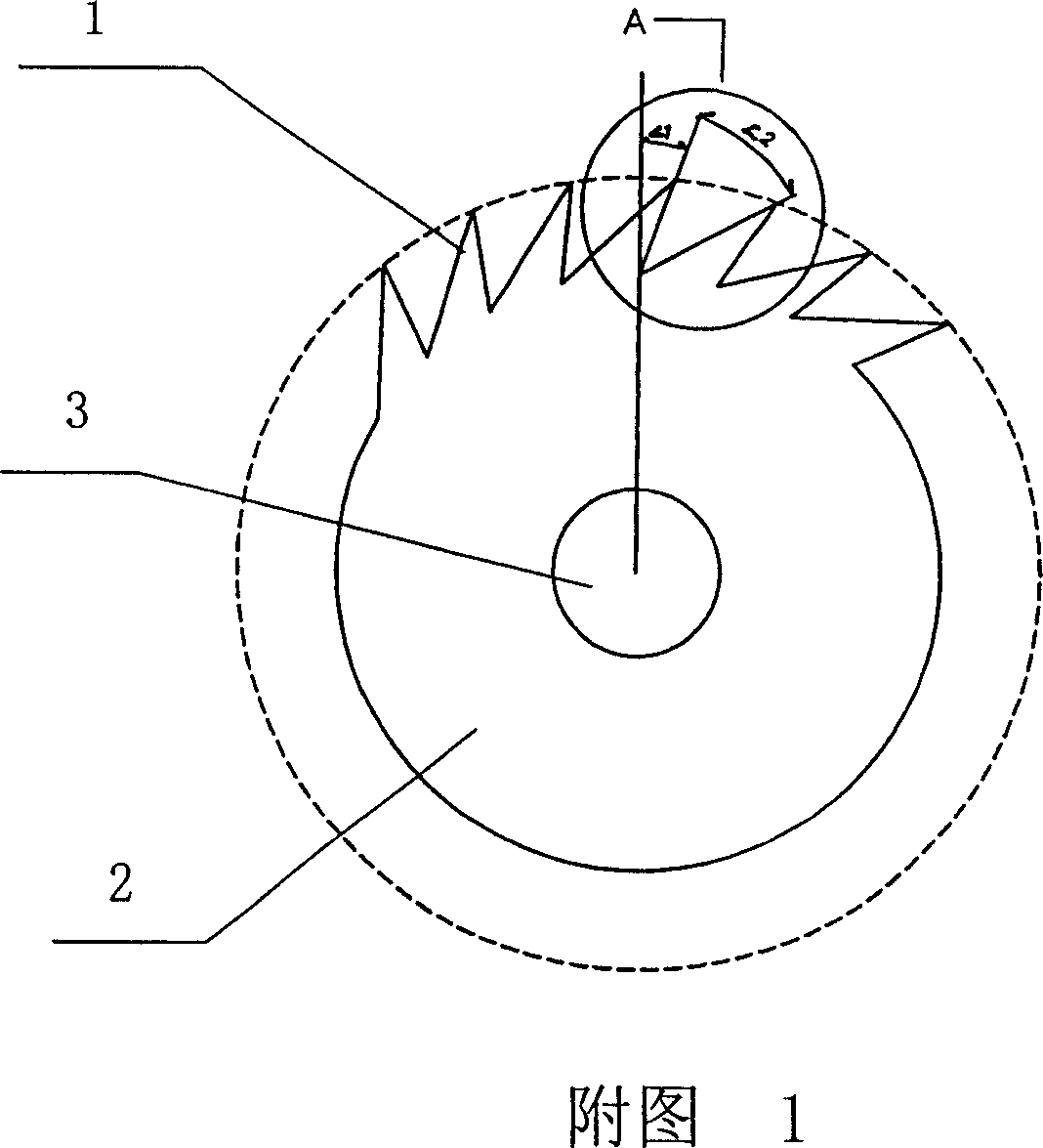

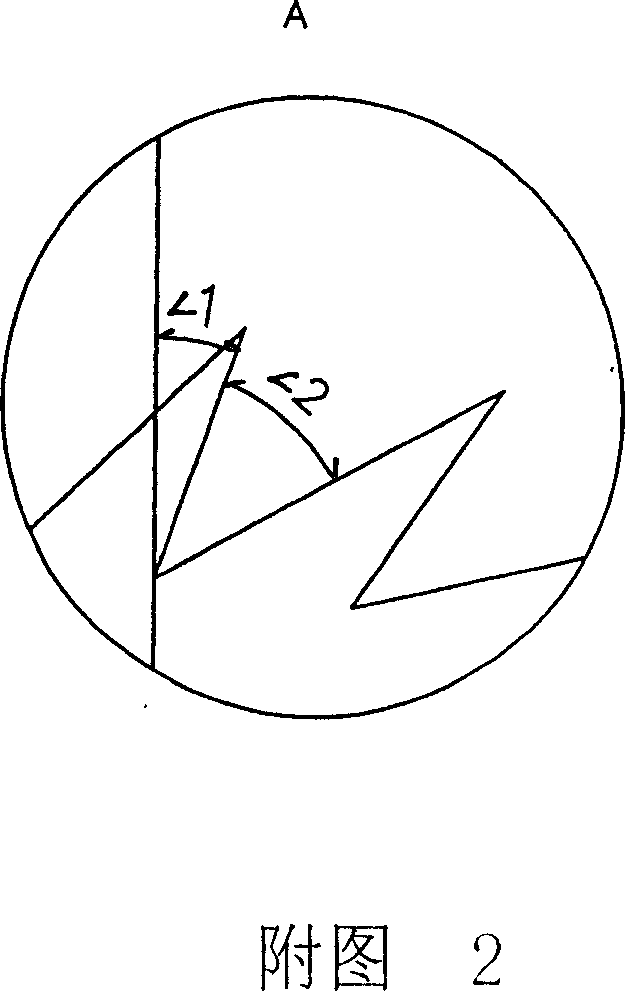

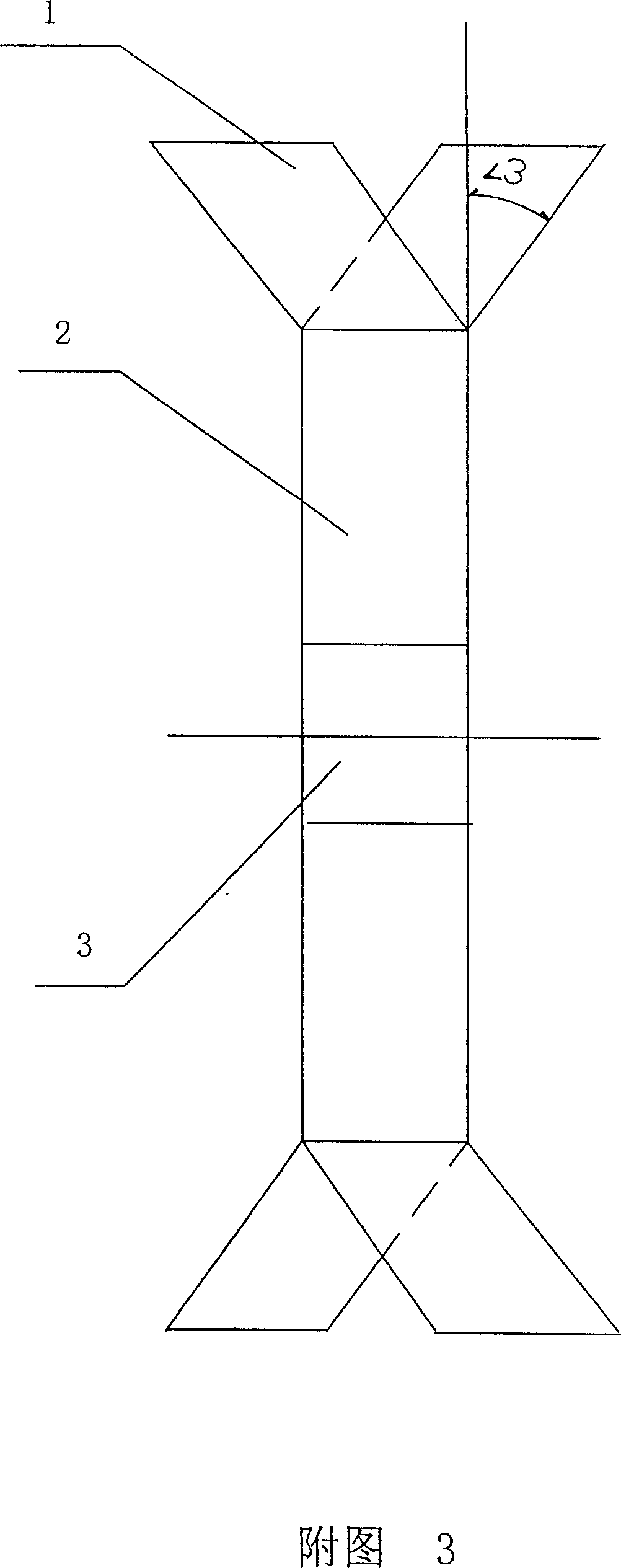

[0063]Referring to accompanying drawings 1, 2, 3, the cutting saw blade shown in the first embodiment of the present invention has the circular saw blade body 2 with the circular inner hole 3 in the center and the continuous teeth on the edge of the circular saw blade body. 1, the tips of the teeth on the outer edge of the cutting saw blade are alternately located on both sides of the plane where the saw blade body is located. The included angle ∠3 between the plane where each tooth is located and the plane where the saw blade body is located is 3°, each tooth is tilted forward, the front angle ∠1 angle is 15°, and the tooth groove ∠2 angle between two adjacent teeth is 55°.

[0064] The second embodiment of the present invention is also composed of a circular saw blade body with a circular inner hole in the center and continuous teeth on the edge of the circular saw blade body, and the tooth tips of some teeth on the outer edge of the cutting saw blade alternate The ground is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com