Multistage heading machine

A multi-stage, shape machine technology, applied in the direction of presses, forging presses, forging presses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

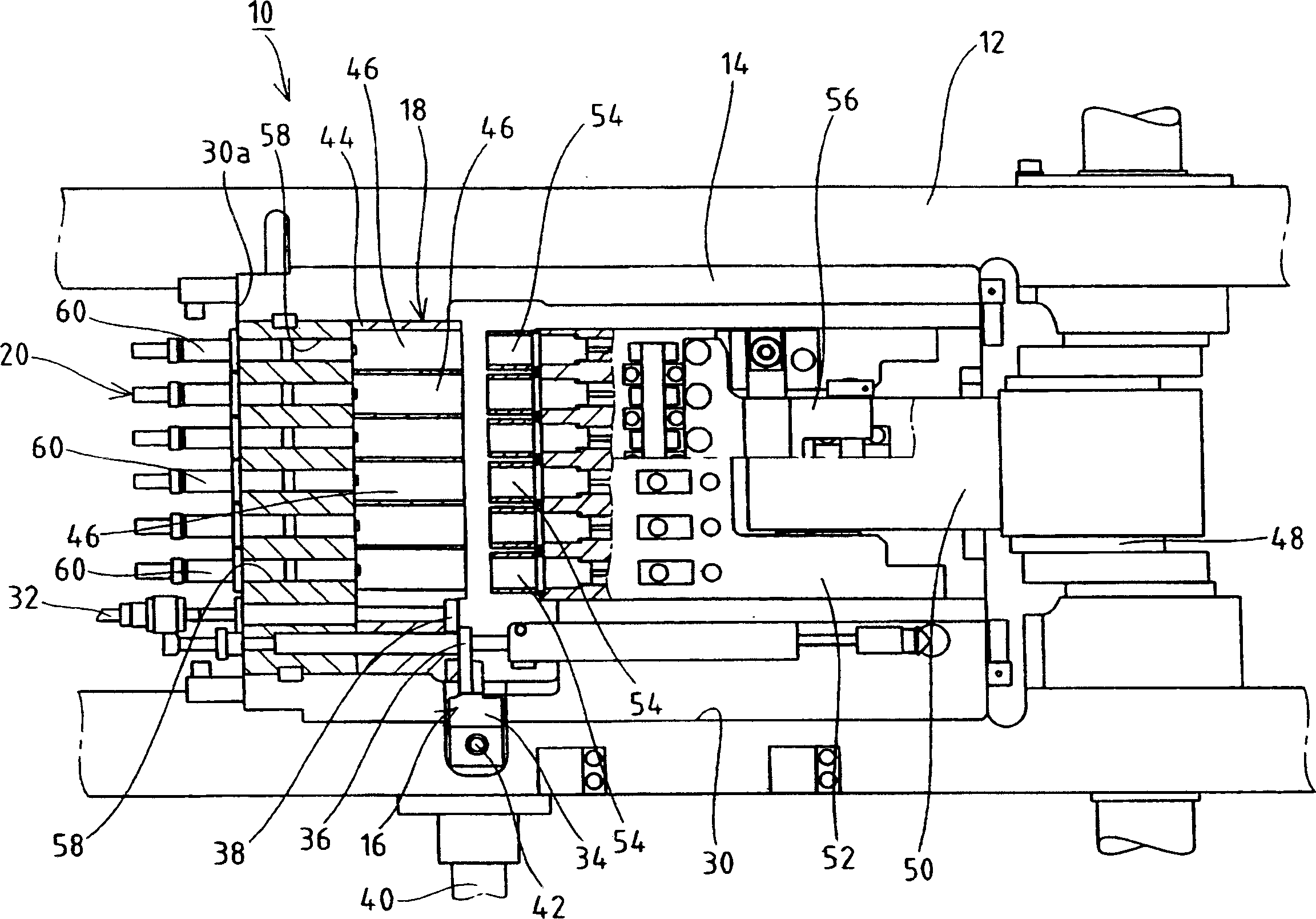

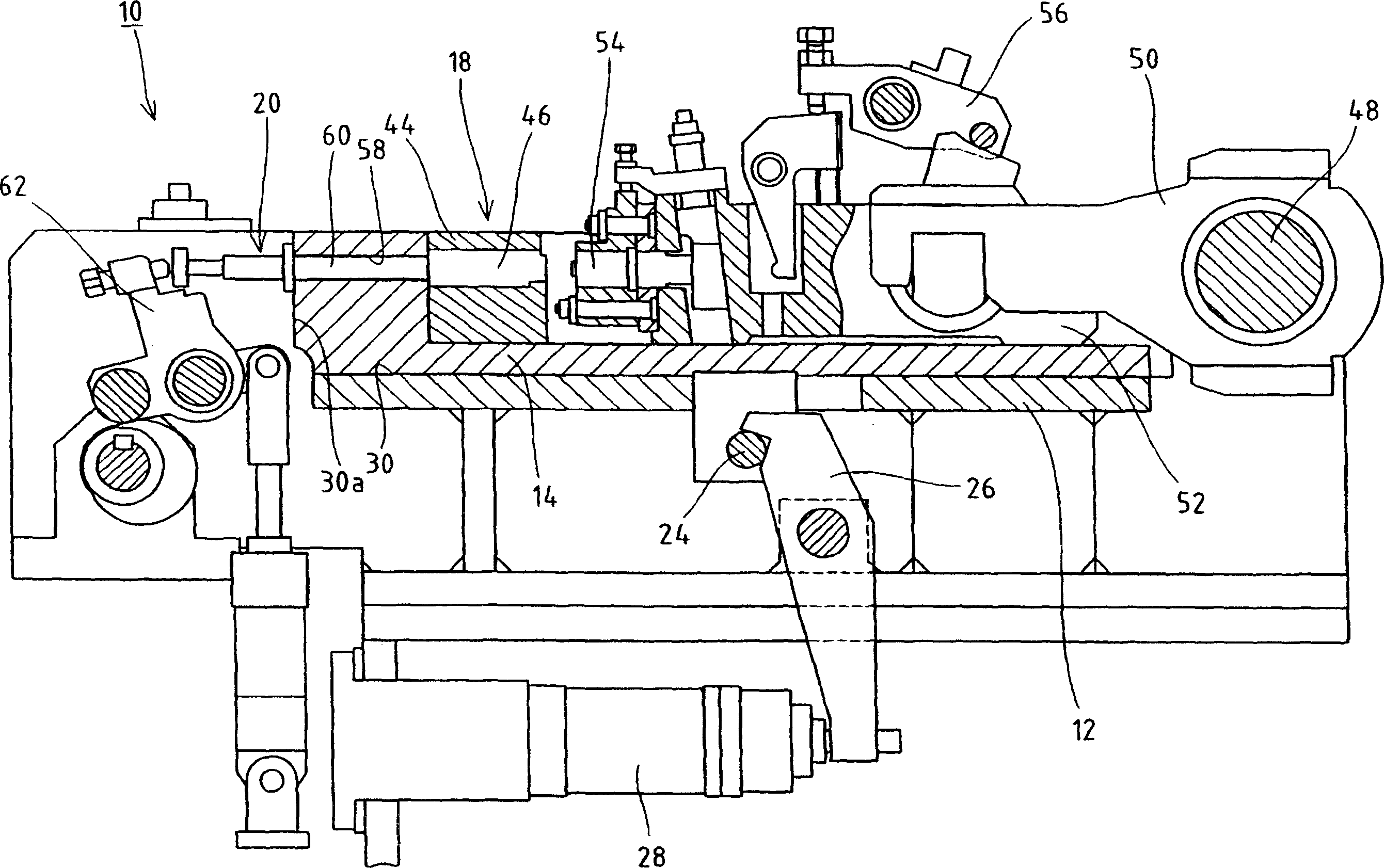

[0032] figure 1 The multi-stage press forming machine 10 of the first embodiment shown includes a mounting table 14 that can be detached from the device frame 12, and the mounting table 14 is equipped with a cutting mechanism 16 and a multi-stage pressing mechanism 18, which will be described later. , The extrusion mechanism 20 and the transfer mechanism 22 are boxed. The installation table 14, such as figure 2 As shown, the engaging member 24 is arranged, and the engaged member 26 that can be engaged and disengaged with respect to the engaging member 24 is rotatably arranged on the device frame 12. On the lower end of the pivot support of the engaged member 26, a hydraulic cylinder 28 as an operating mechanism arranged on the device frame 12 is connected, and the hydraulic cylinder 28 exerts a forward or reverse action. The force causes the upper end portion of the pivot support portion of the engaged member 26 to move (tilt movement) between the engagement position with respe...

Embodiment 2

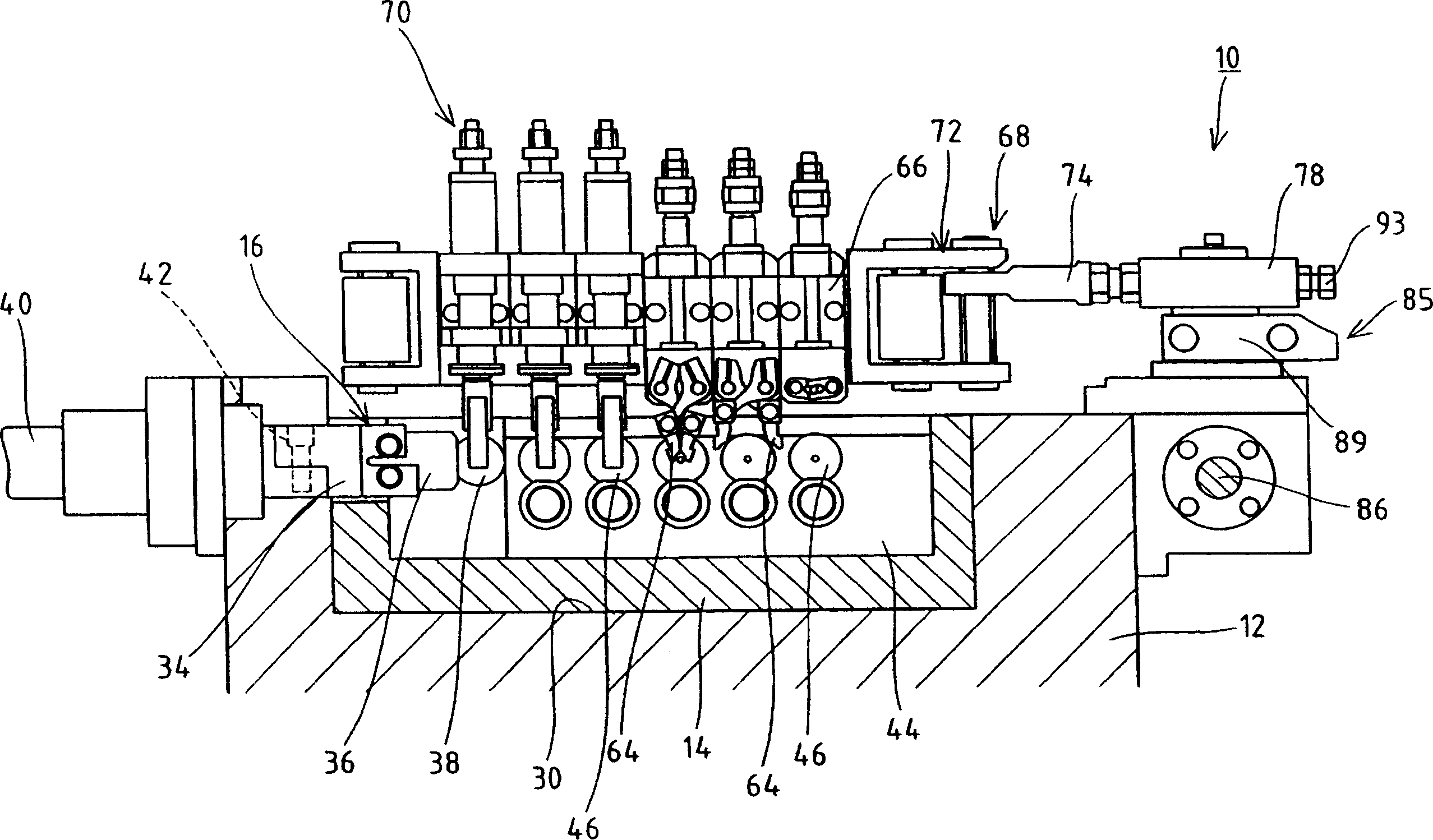

[0057] Figure 7 and Figure 8 It is a diagram showing another example of the eccentric structure used in the multi-stage press forming machine of the second embodiment. The basic structure is the same as that of the first embodiment, so only the different parts will be described. The existing same components The same reference numerals are indicated.

[0058] In this second embodiment, the drive mechanism 85 is provided with a swinging member 89 arranged on the first drive shaft 88, which is vertically arranged at a position eccentric from the arrangement position of the first drive shaft 88 and protrudes by a predetermined height.轴95. In addition, the swing shaft 95 swings in a circular arc shape with the drive shaft 88 as the center along with the forward and reverse rotation of the first drive shaft 88 within a desired angle range. On the other hand, the eccentric sleeve 96 is externally fitted on the swing shaft 95 through the bearings 92 and 92 in a relatively rotatable stat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com