Membrane filter unit and method for the production of a membrane filter unit

A technology of membrane filtration and membrane, which is applied in the field of membrane filtration unit and can solve problems such as inappropriateness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

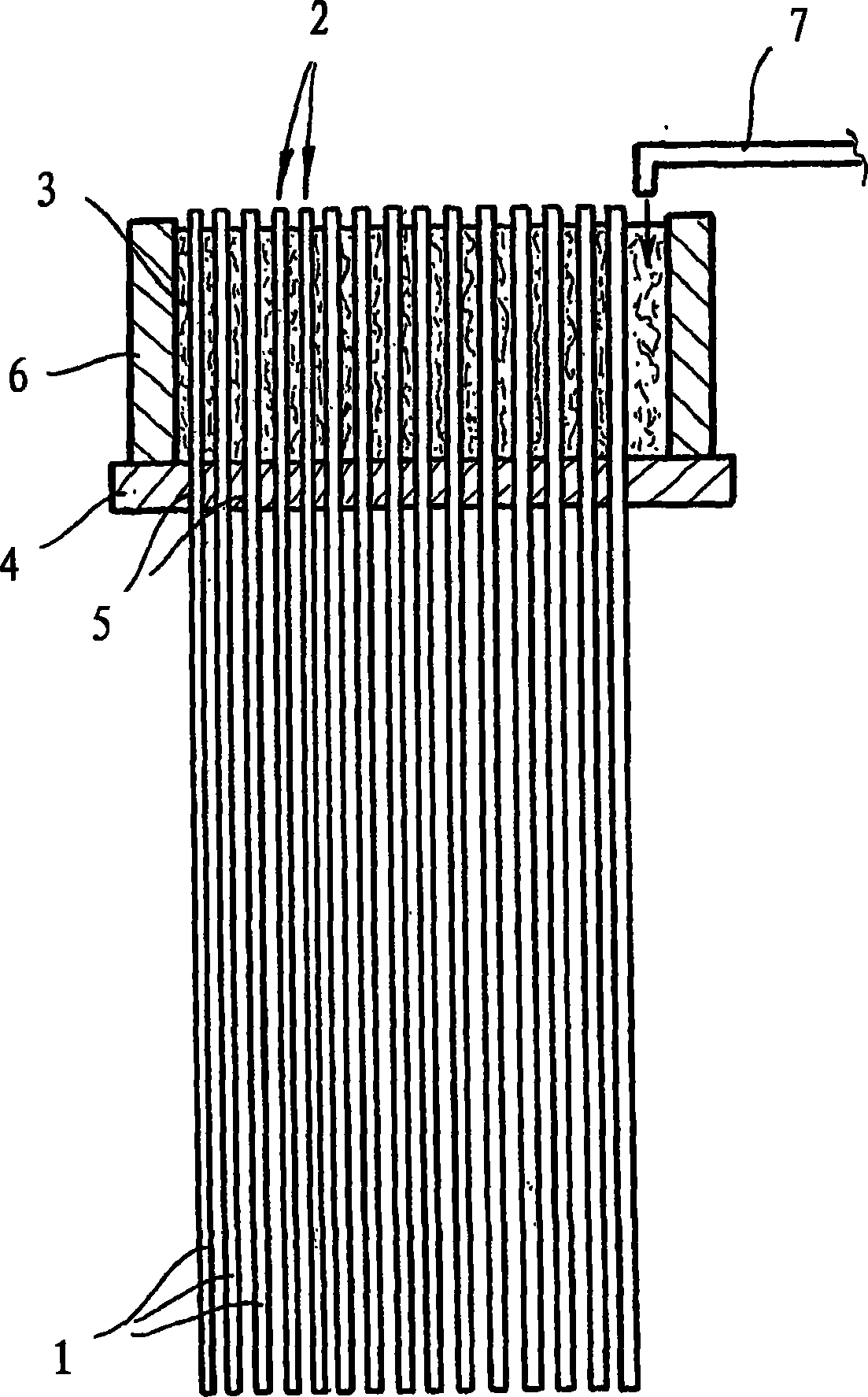

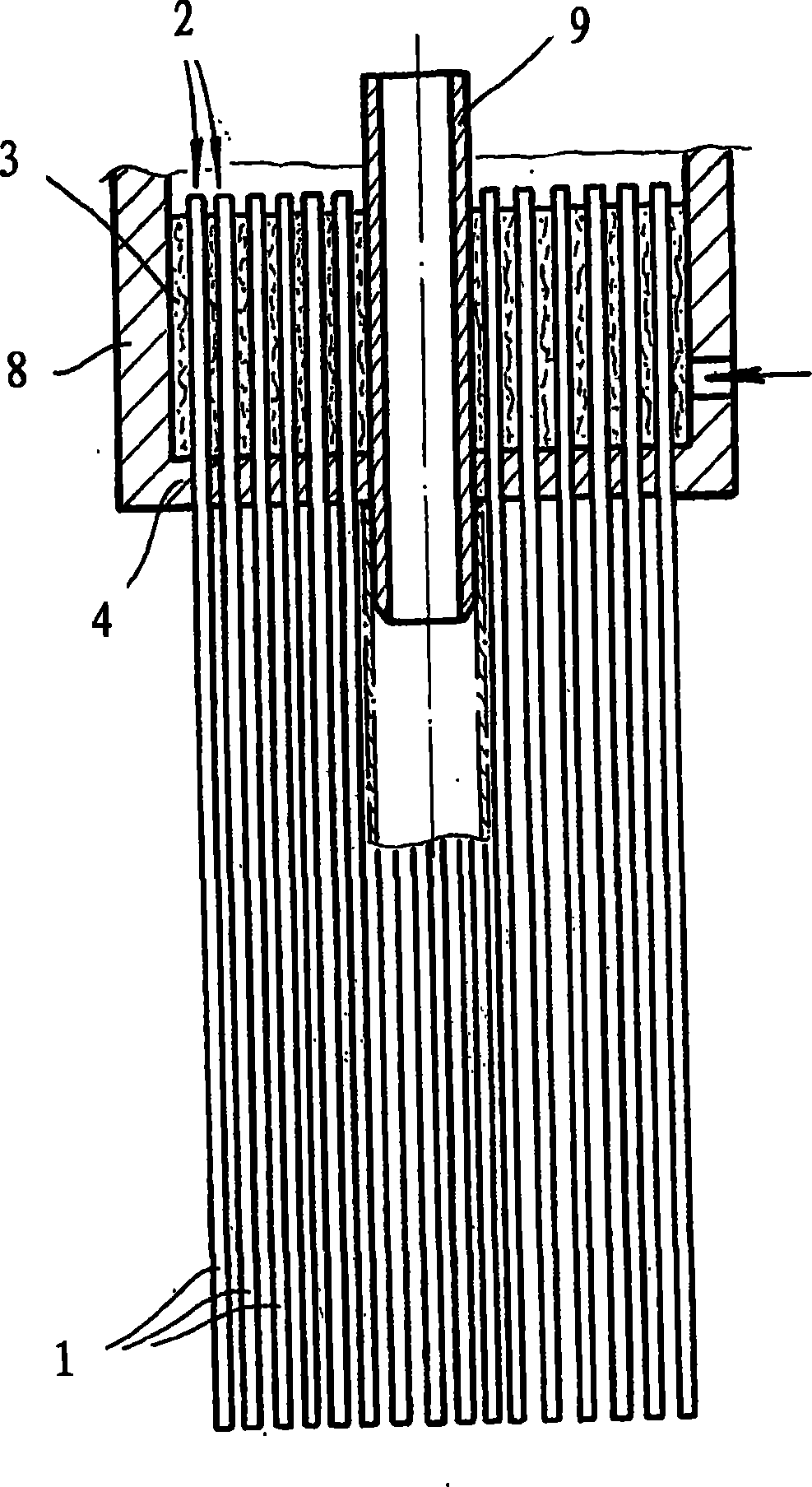

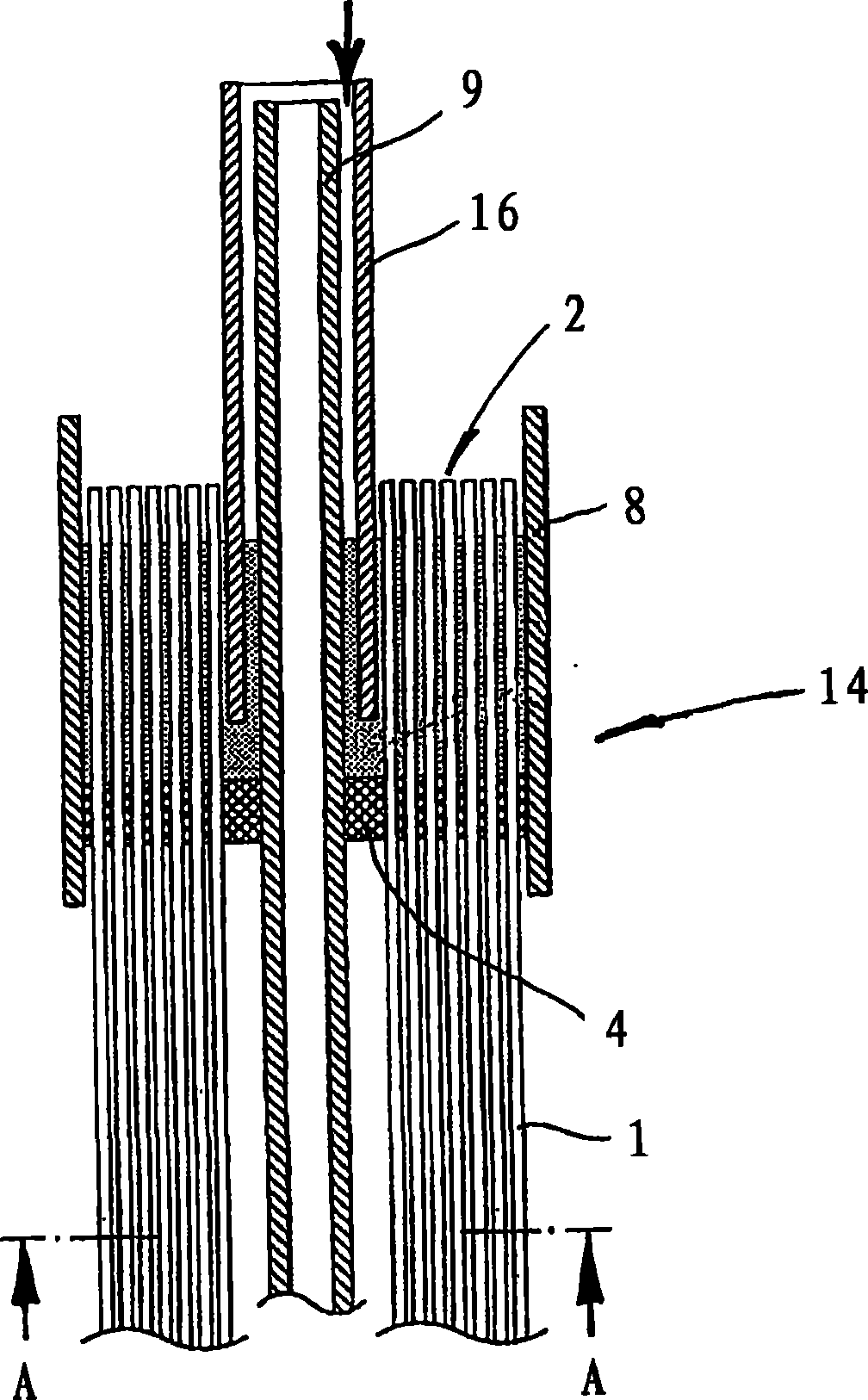

[0018] The drawing shows a membrane filtration unit for liquid or gaseous media, which has a bundle or an arbitrarily arranged plurality of capillary membranes 1 open at least at one end, which are cast into a desired area in the vicinity of the ends of the membrane open ends 2. Hardened into a solid head within the sealing layer 3. As can be seen from the view, the film open end 2 protrudes on the top surface of the sealing layer 3, ie on the outside of the head. The sealing layer 3 is attached with the side of the open end 2 of the back capillary film 1 to the upwardly facing side of the spacer 4 . The spacer 4 has a layer which is penetrated by the capillary film 1 and which is impermeable, or at least substantially impermeable, to the casting material to be hardened into the sealing layer 3 . exist figure 1 In the embodiment of the invention the spacer 4 consists of a perforated plate, the holes 5 of which surround the capillary membrane substantially without gaps. Depe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com