Actuator

A driver and driven technology, applied in the direction of instruments, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem of increasing the number of drivers and achieve the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, preferred embodiments of the actuator of the present invention will be described in detail with reference to the drawings.

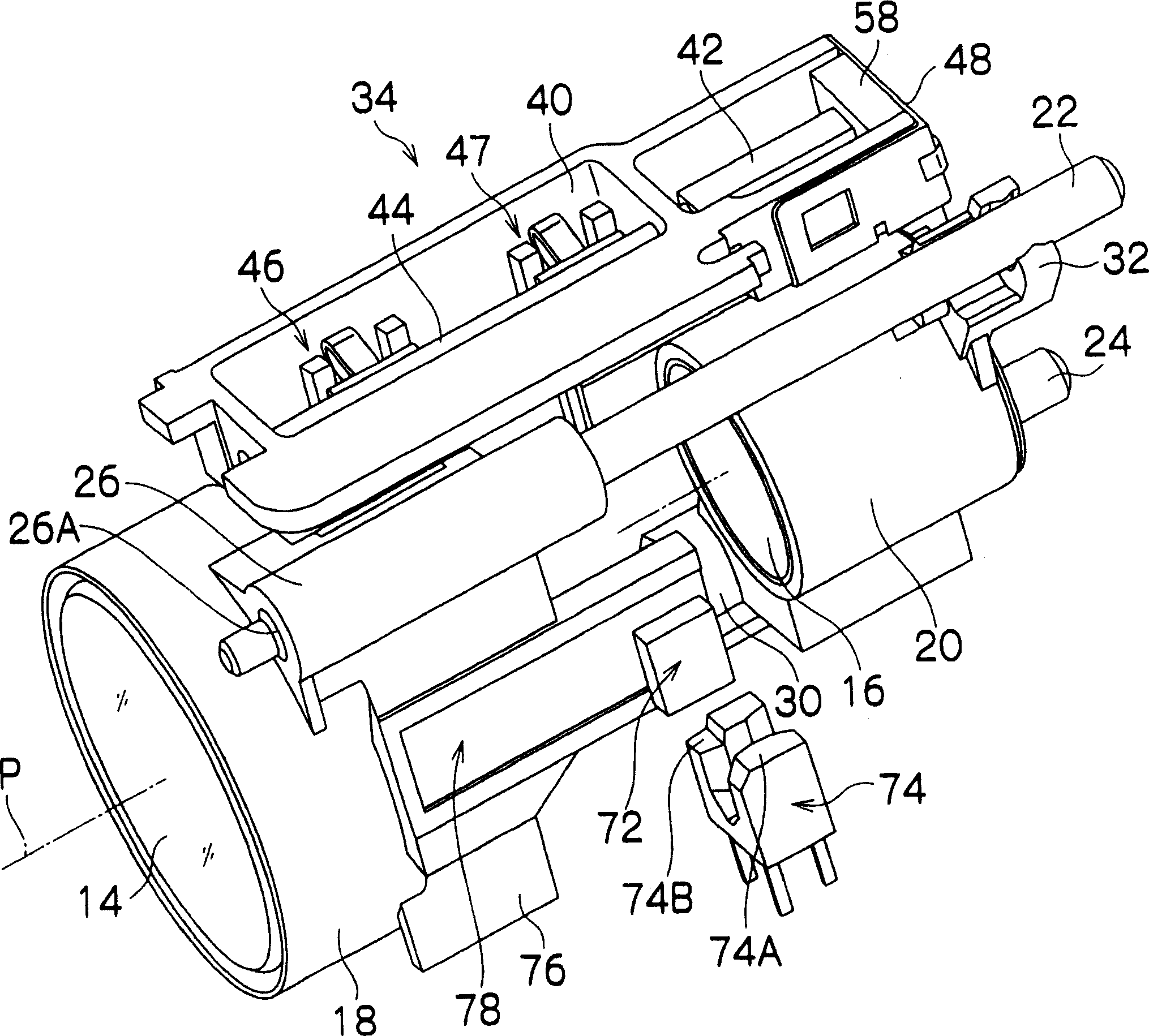

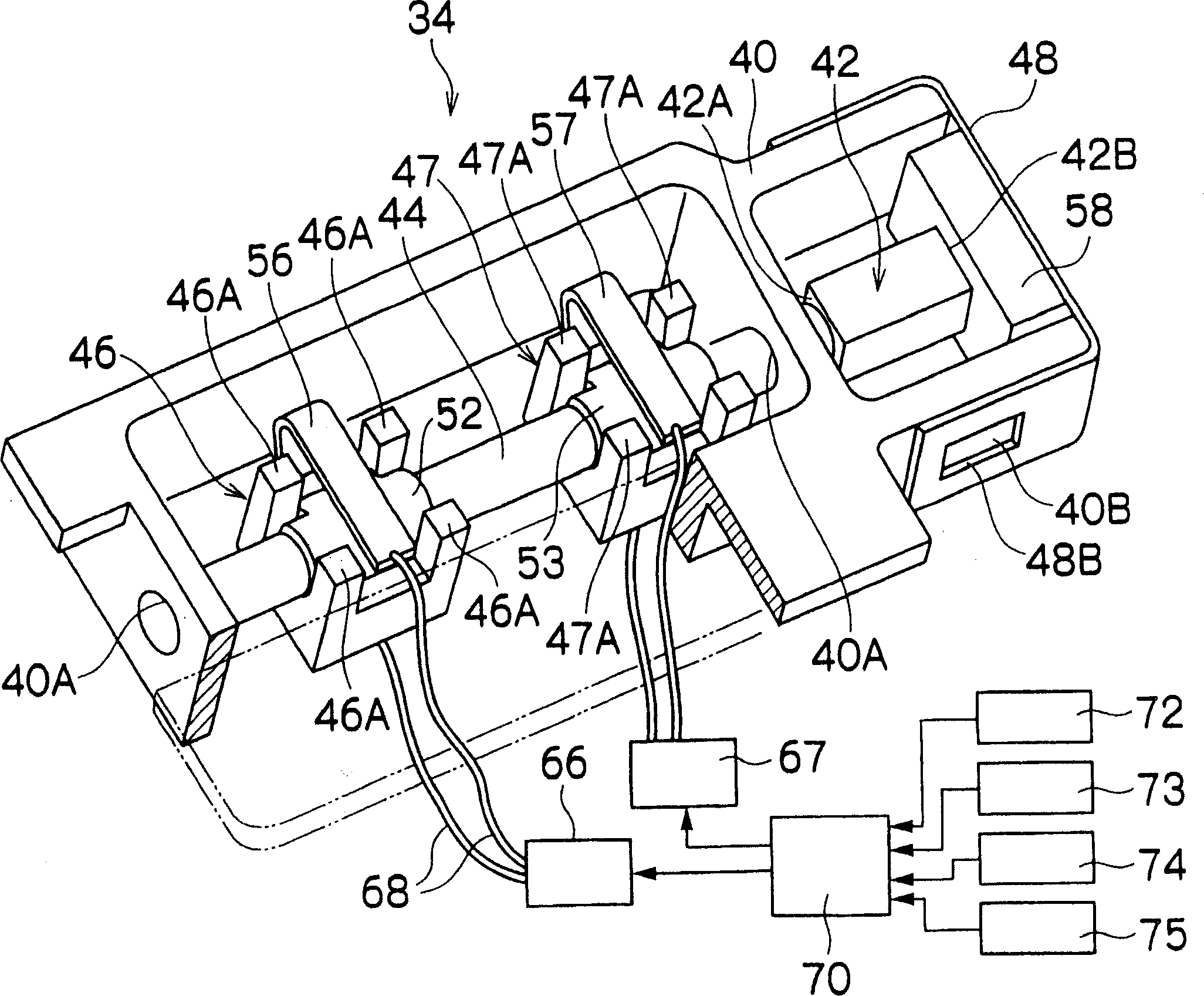

[0027] figure 1 It is a perspective view showing a lens device 10 to which an actuator of the present invention is applied, figure 2 It is a perspective view showing its internal structure.

[0028] Such as figure 1 As shown, the lens device 10 has a body 12 formed in a substantially rectangular shape, and the inside of the body 12 is equipped with figure 2 Zoom lens (sets) 14, 16 are shown. One of the zoom lenses (groups) 14 and 16 is a zoom lens, and the other is a correction lens. Further, the zoom lenses (groups) 14 , 16 are held by holding frames 18 , 20 , respectively, and the holding frames 18 , 20 are slidably supported in the direction of the optical axis P by two guide shafts 22 , 24 . The two guide shafts 22 and 24 are arranged at diagonal positions inside the main body 12 and parallel to the optical axis P, and are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com