Preparation method of coal series needle shaped coke

A needle coke, coal-based technology, used in coke ovens, tar pitch/petroleum pitch/natural pitch processing, coking carbon-containing materials, etc., can solve the problems of low raw material utilization rate and high production cost, and achieve good product quality. , the effect of increased aspect ratio and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

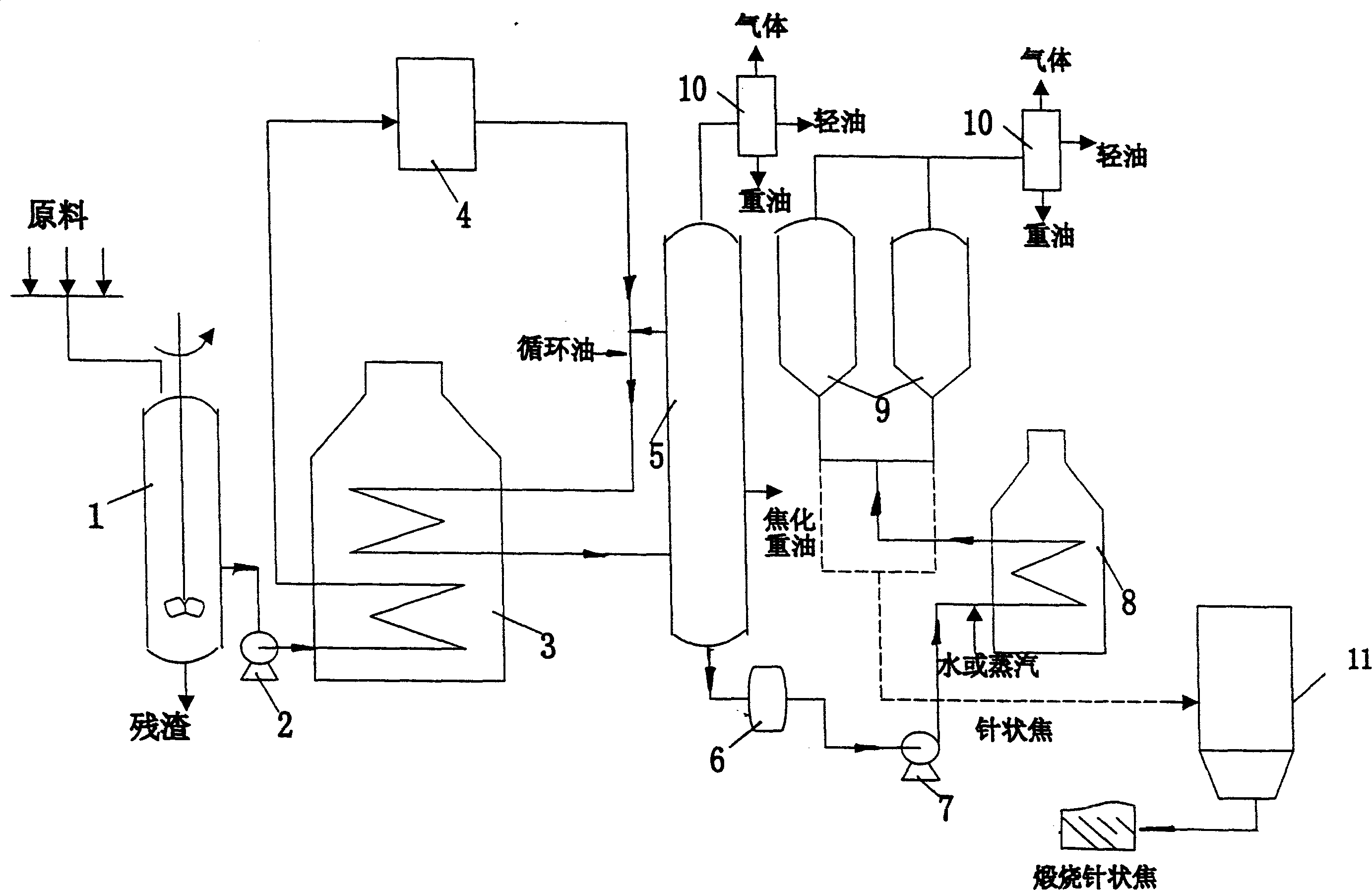

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0013] As shown in the drawings, the preparation method of coal-based needle coke in this example uses coal tar pitch, coal tar, and heavy fractions of coal tar as raw materials, and is prepared through preparation, purification, polycondensation, coking, and calcination to produce coal-based needle coke. State coke, of which:

[0014] (1) Preparation: first, coal tar pitch, coal tar, coal tar heavy fraction raw materials and auxiliary agents anthracene oil and medium oil are added to the mixed solvent tank 1 for preparation;

[0015] (2) Purify: the raw material after modulation is sent into heating in tubular heating furnace 3 by raw material pump 2, then enters in purifying device 4, makes the raw material after heating remove quinoline insoluble matter through settling, centrifugation, filtration, makes quinoline Phenyl insoluble matter <...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com