Minitype vertical liquid packing machine

A packaging machine and liquid technology, applied in packaging, liquid materials, transportation packaging, etc., can solve the problems of unsuitable multi-variety classification filling, unsuitable for small batch filling, large volume of packaging machinery, etc., and achieve the liquid flow path Less, less liquid pollution, high degree of work automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further illustrate the present invention, below in conjunction with embodiment is described in more detail.

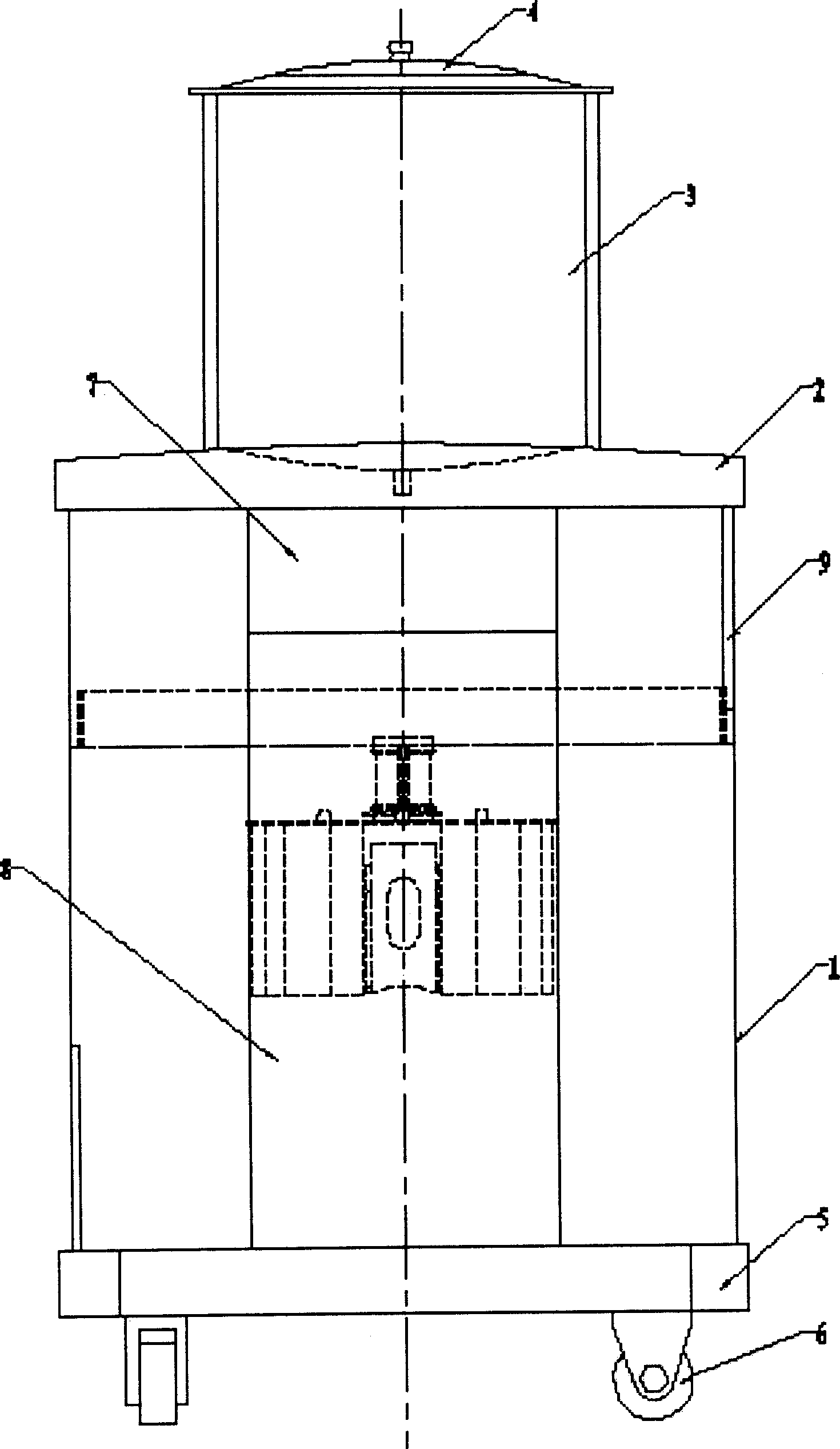

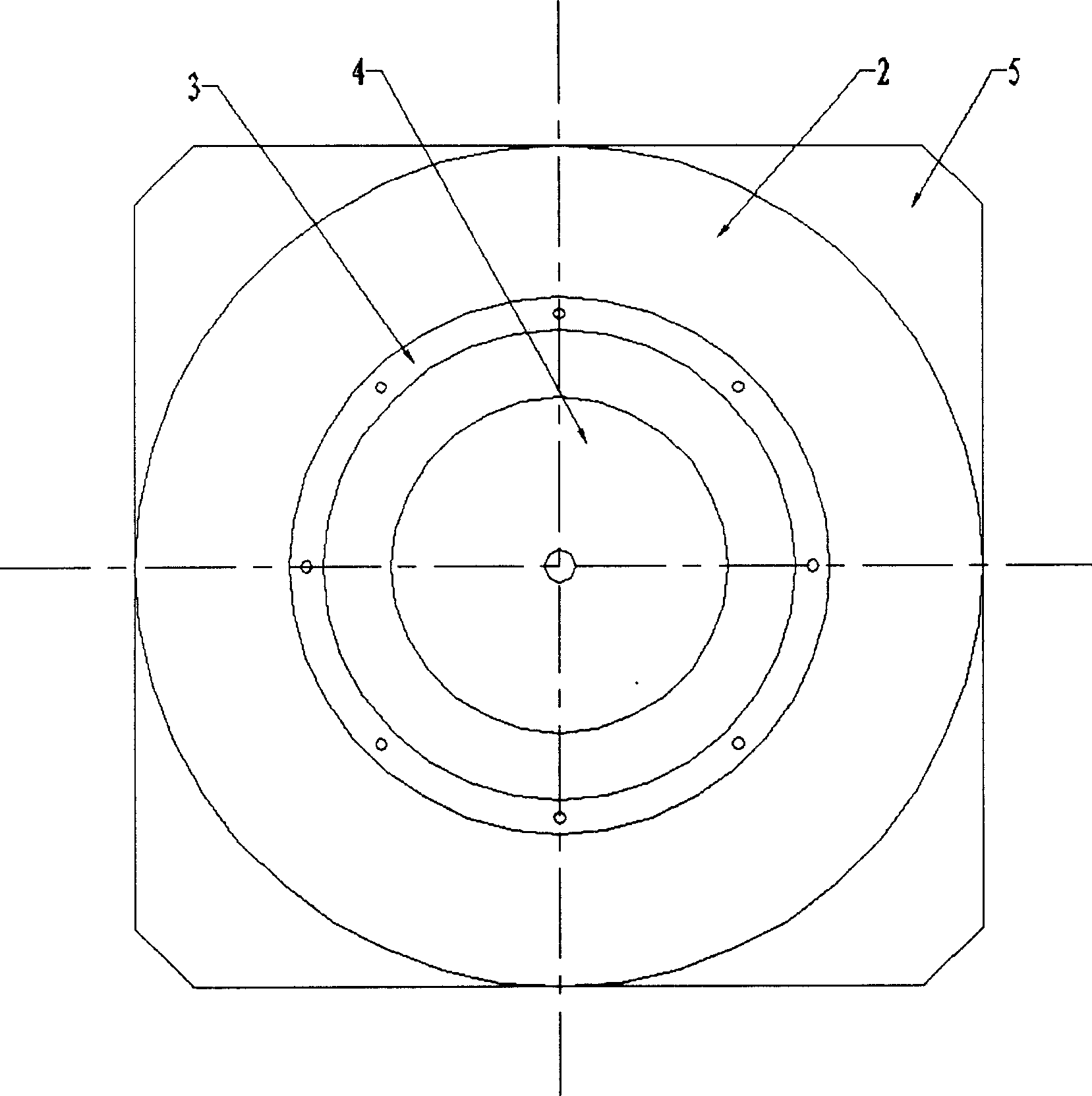

[0020] figure 1 It is the front view of the whole machine of the small vertical liquid packaging machine of the present invention. There is a box cover 2 on the cylindrical case 1, a liquid tank 3 is arranged on the case cover 2, an openable tank cover 4 is placed on the liquid tank 3, and the case is under 1. Be square support 5, four jiaos respectively have a machine wheel 6, are convenient to move, and cabinet 1 is provided with packing assembly. figure 2 is its top view, for reference.

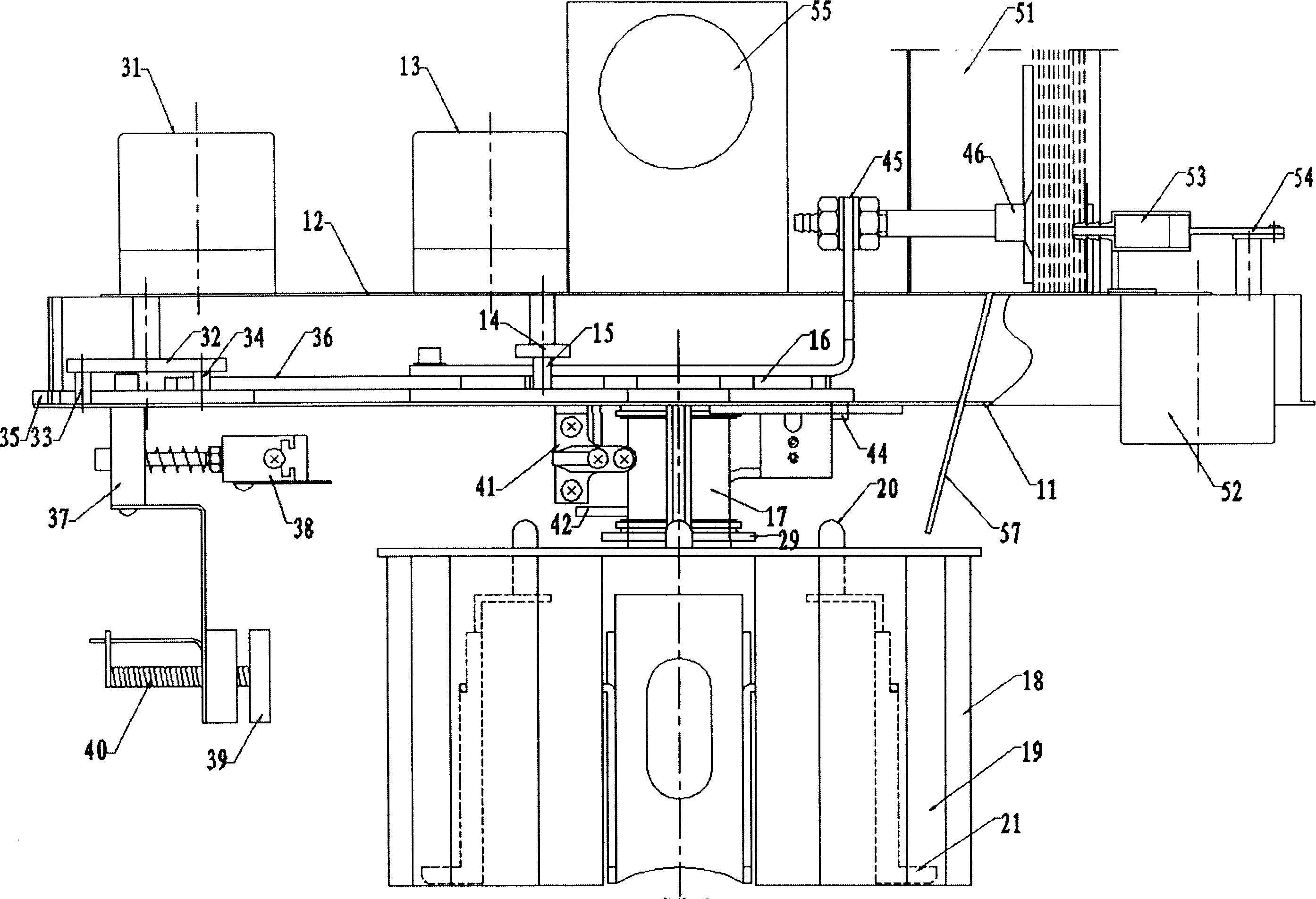

[0021] The packaging assembly includes a rotating mechanism, a main control mechanism, a bag supply mechanism, a filling mechanism, a sealing mechanism, and a groove-shaped lower frame 11 connected to the cabinet 1 and an upper frame 12 buckled thereon, (see image 3 , Figure 4 , Figure 5 ), the rotary mechanism is composed of plum blossom wheel 16 and run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com