Holding device for an optical element in an objective

A technology of optical components and devices, applied in optics, instruments, optomechanical equipment, etc., can solve problems such as exposure deterioration, damage to precision parts, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

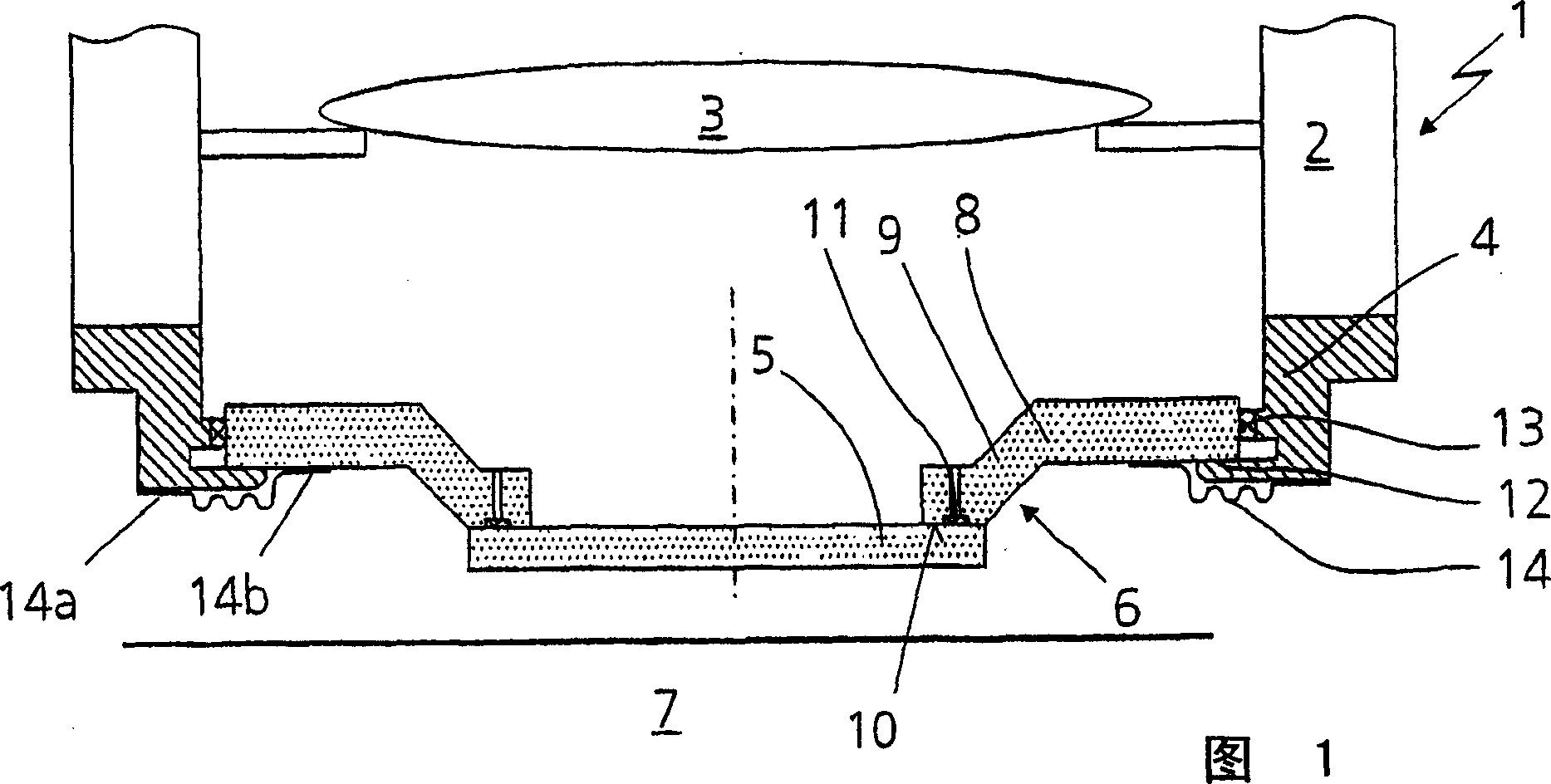

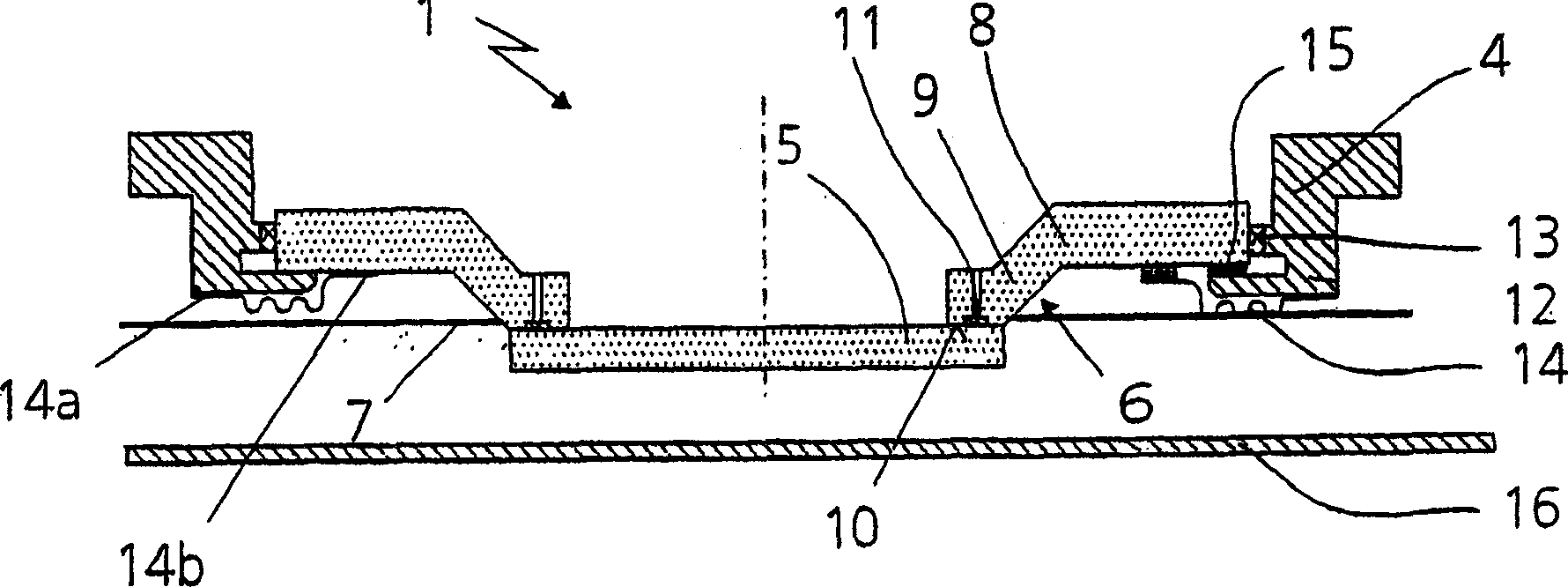

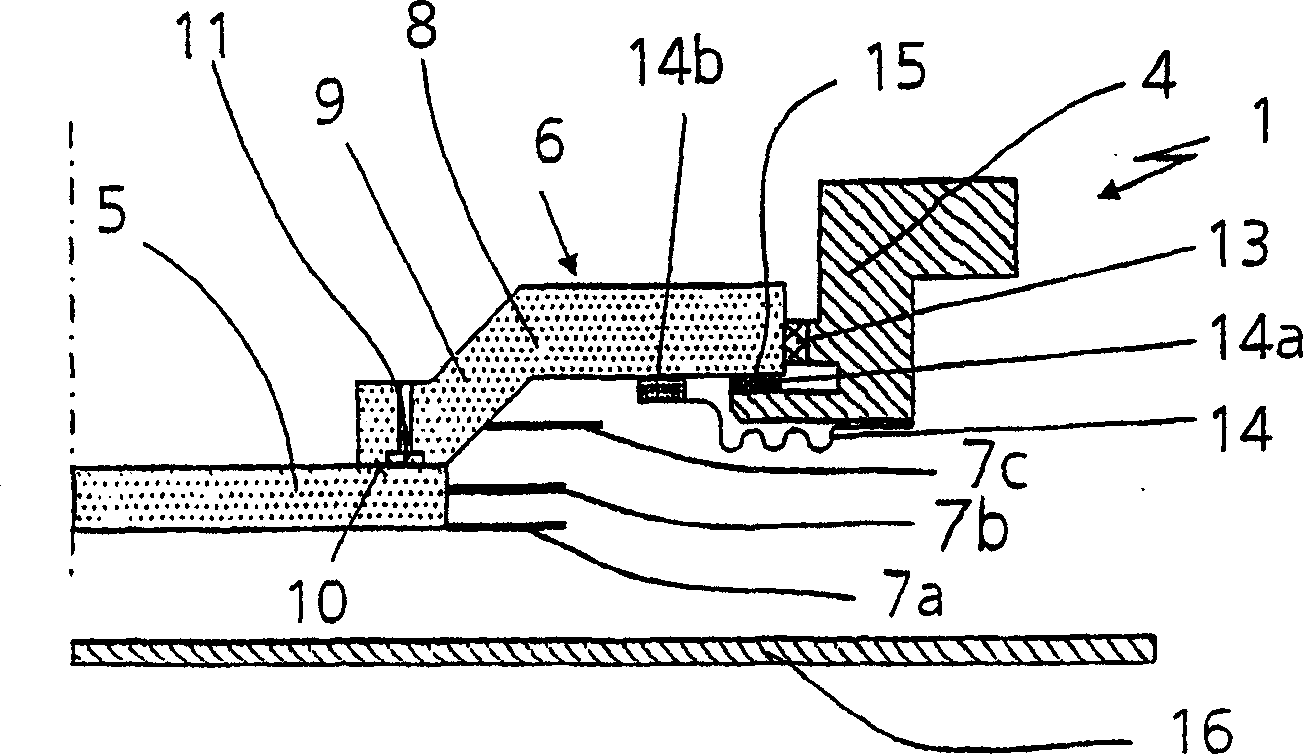

[0040] FIG. 1 shows a first embodiment of an objective designed as a lithography objective 1 and suitable especially for immersion lithography, but also for other types of lithography and also for other purposes. Since immersion lithography is known per se, this method will not be explained in detail here. The lithography objective 1 has a housing 2 , which is very schematically represented, and inside which a plurality of optical elements 3 are arranged in a manner known per se, although the number and arrangement of the optical elements is only schematic.

[0041] On the bottom of the housing 2 is mounted a base structure or base 4 which is secured to the housing 2, for example by bolts (not shown), so as to be detachably connected to said housing. Of course, other types of connections are also conceivable for connecting the base 4 to the housing 2 , by means of which the base 4 can be removed from the housing 2 . The base 4 serves to accommodate a terminal plate or termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com