Drum washing machine

一种滚筒洗衣机、洗衣桶的技术,应用在其他洗衣机、洗涤容器、洗涤装置等方向,能够解决移至冷凝导管的外部、洗衣桶不会被均匀地支撑等问题,达到增加方便性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

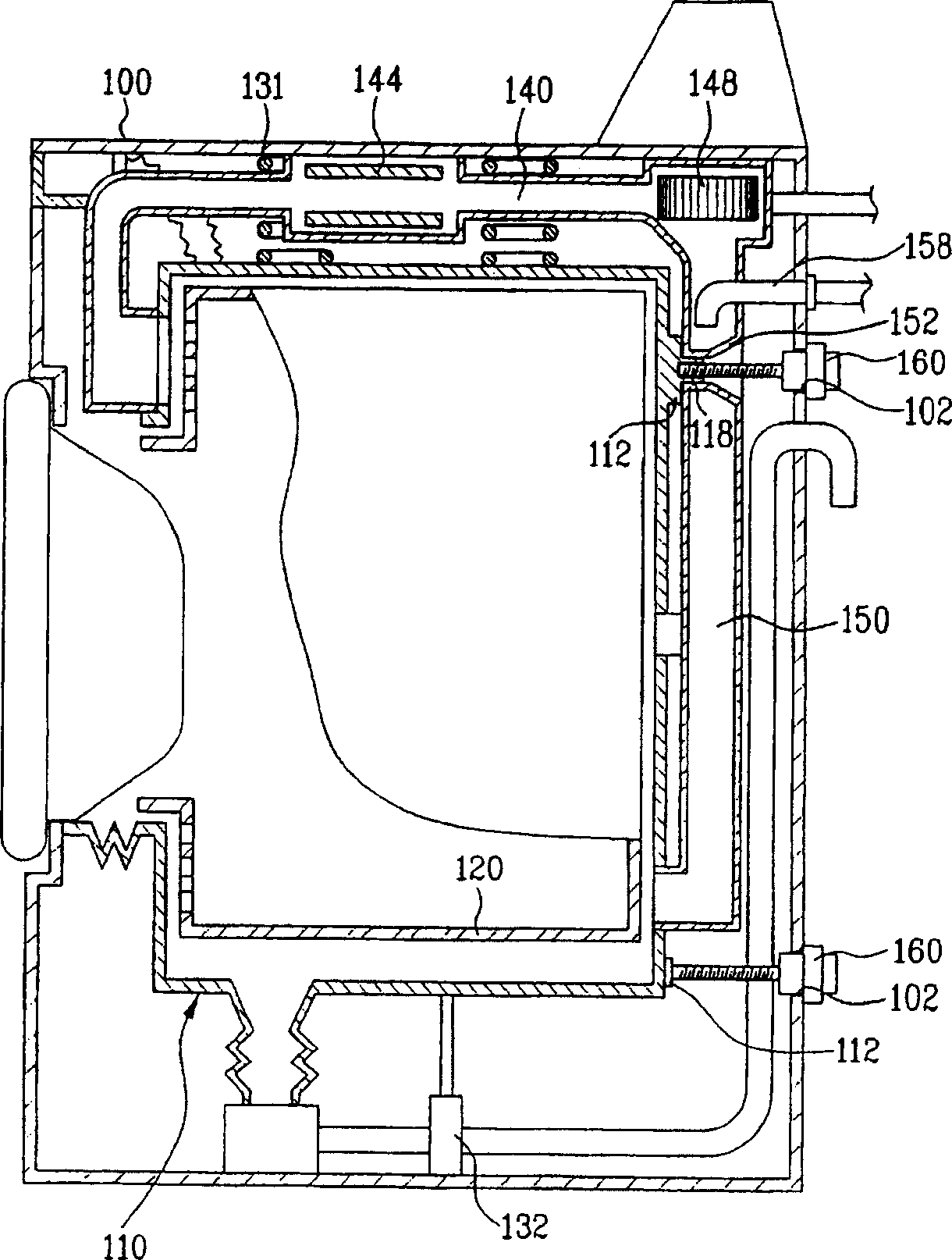

[0035] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0036] refer to Figures 3 to 5 , the structure of the drum washing machine of the present invention will be described. Such as Figures 3 to 4 As shown, a washing tub 110 storing washing water is installed in the cabinet 100 , and a drum 120 is rotatably installed inside the drum 110 . A motor (not shown) for transmitting driving force to the drum 120 is installed at a rear side of the tub 100 . The upper end of the washing tub 100 is supported by a plurality of springs 131 suspended on the casing 100 , and the lower end thereof is supported by a plurality of shock absorbers 132 .

[0037] The drying duct 140 is disposed at an upper portion of the washing tub 110 . A fan 148 and a drying heater 144 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com