Screw pile, thread pile piling equipment and piling method

A technology of threaded piles and screw piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of insufficient self-weight of equipment, failure to achieve occlusal, insufficient pressure, etc., achieve power output, save electricity and time, and expand applications The effect of increasing the range and drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

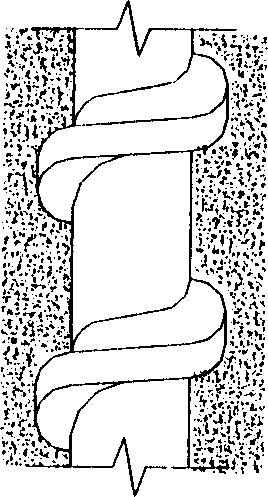

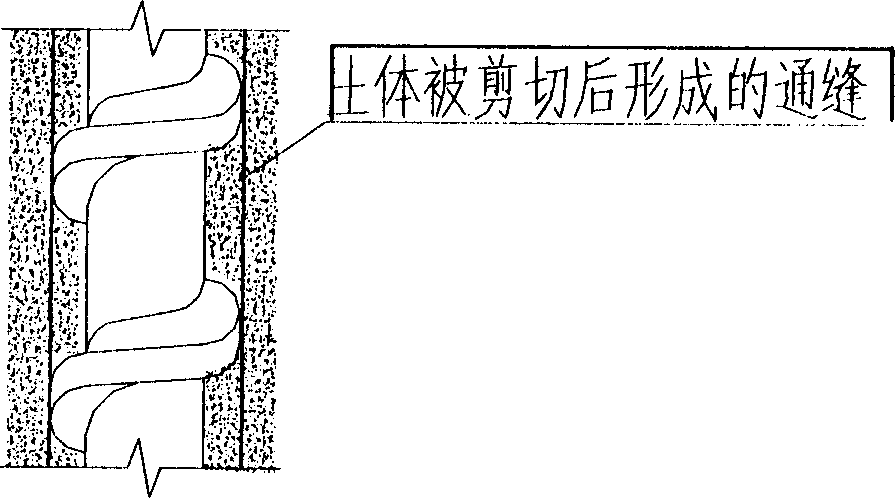

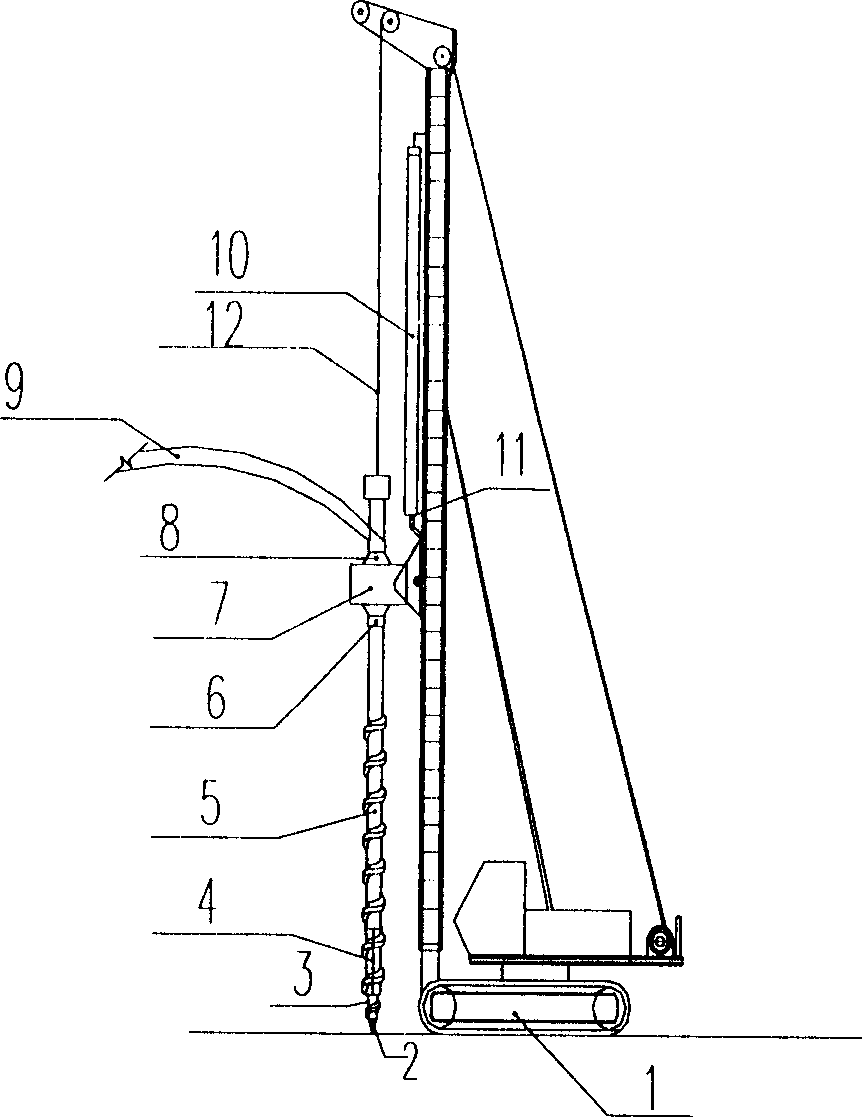

[0033] Structural drawings further describe the present invention.

[0034] Such as image 3 , Figure 4 As shown, the pile-forming equipment of screw pile and screw pile of the present invention mainly consists of the following components: a body, an oil cylinder, a motor, an automatic control device, and a delivery pipeline. The body mainly includes a frame 1, a power head 7 and a drill rod 6, The power head 7 is installed on the stand of the frame 1, the motor 16 is installed on the body base 1, the motor 16 is connected with the power head 7 through the telescopic oil cylinder 10, the fixture 8 on the drill pipe 6 is connected with the movable fixture 8 of the power head 7 Connected, the power head and the inner drill pipe 6-1 are connected with a reciprocating helical bayonet 14, the concrete delivery pipeline 9 is connected with the inner drill pipe 6-1, and the lower end of the telescopic oil cylinder 10 is provided with a feed speed sensor 11, and the oil cylinder Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com