Deep hole boring and drilling machine for roller production

A technology of deep hole boring and drilling machine, which is applied in the parts of boring machine/drilling machine, boring/drilling, drilling/drilling equipment, etc., which can solve the problems of time-consuming processing, difficulty in processing long holes of rolls, and difficulty in installation of rolls. , to achieve the effect of convenient installation of rolls, convenient adjustment, and increased drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

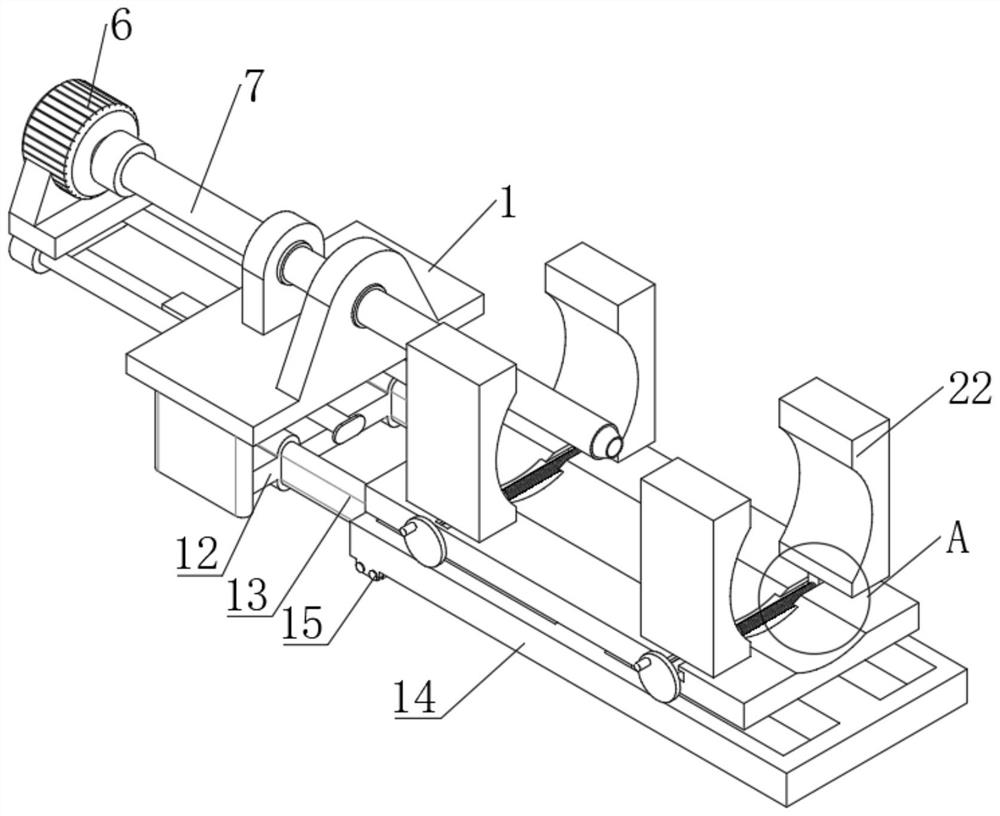

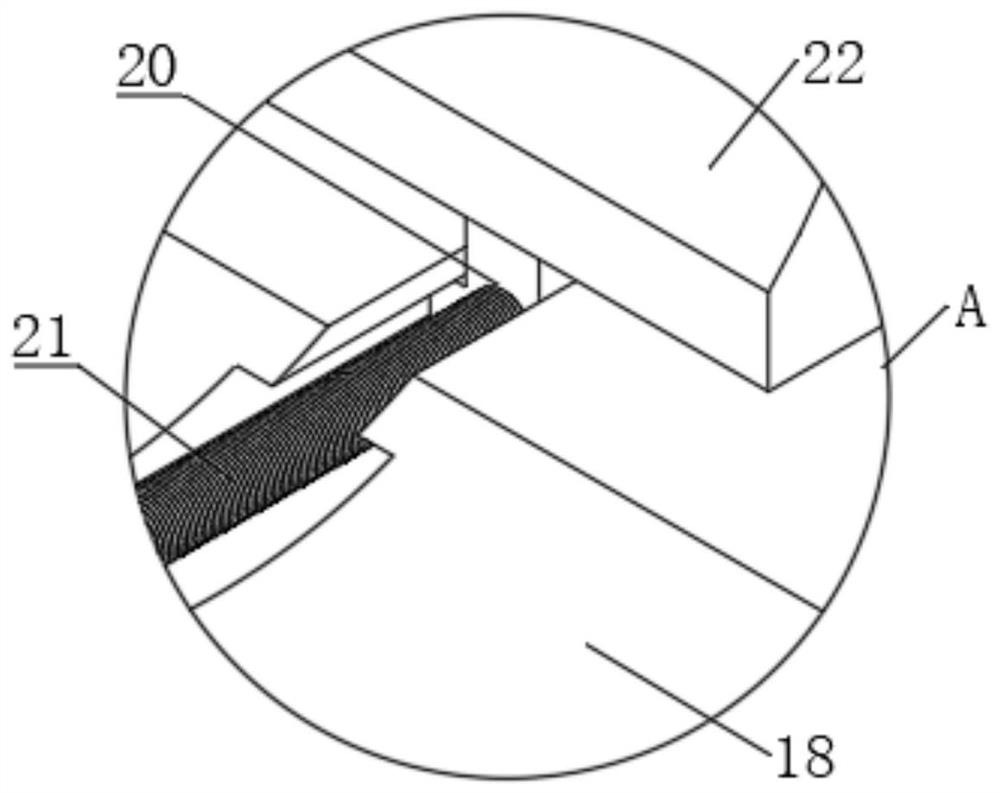

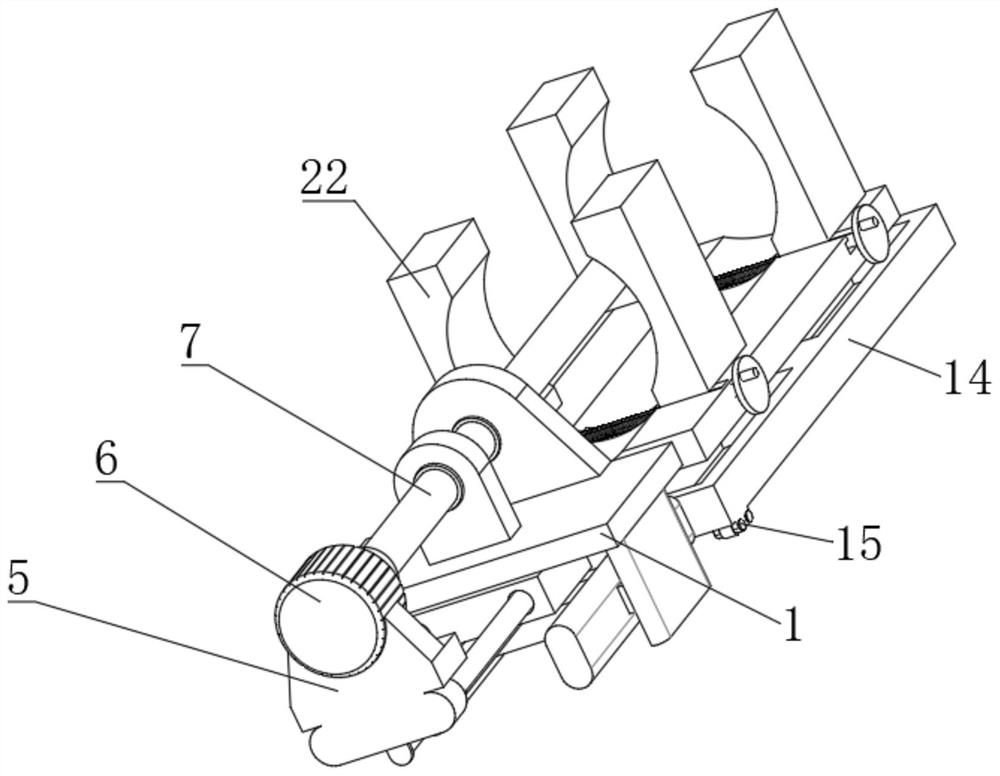

[0036] Such as Figure 1-6 As shown, the embodiment of the present invention provides a deep hole boring and drilling machine for roll production, including a main workbench 1 and an auxiliary workbench 14, the main workbench 1 is composed of two support frames and a support platform, and the support platforms are fixedly connected On the top of the two support frames, it is used to support and install the drilling structure. The bottom surface of the support platform is fixedly connected with the bottom sliding seat 2, and the side of the bottom sliding seat 2 is slidably connected with the sliding rod 3. The sliding rod 3 can be connected to the bottom The sliding seat 2 slides smoothly, so that the axial drilling movement of the transmission shaft 7 is relatively stable when drilling. The left end of the sliding rod 3 is fixedly connected with a connecting support plate 4. The sliding rod 3 is preferably set to two, connecting the supporting plate 4 is used to connect two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com