Bobbin thread holding device for seamer

A holding device and sewing machine technology, applied in the sewing machine to cut off the thread mechanism, sewing machine components, sewing machine collar mechanism, etc., can solve the problems of thread tension reduction, not being able to form knots well, pull out, etc., to achieve sewing quality Improve and realize the sewing quality and reduce the effect of pulling out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] (Overall structure of the embodiment of the invention)

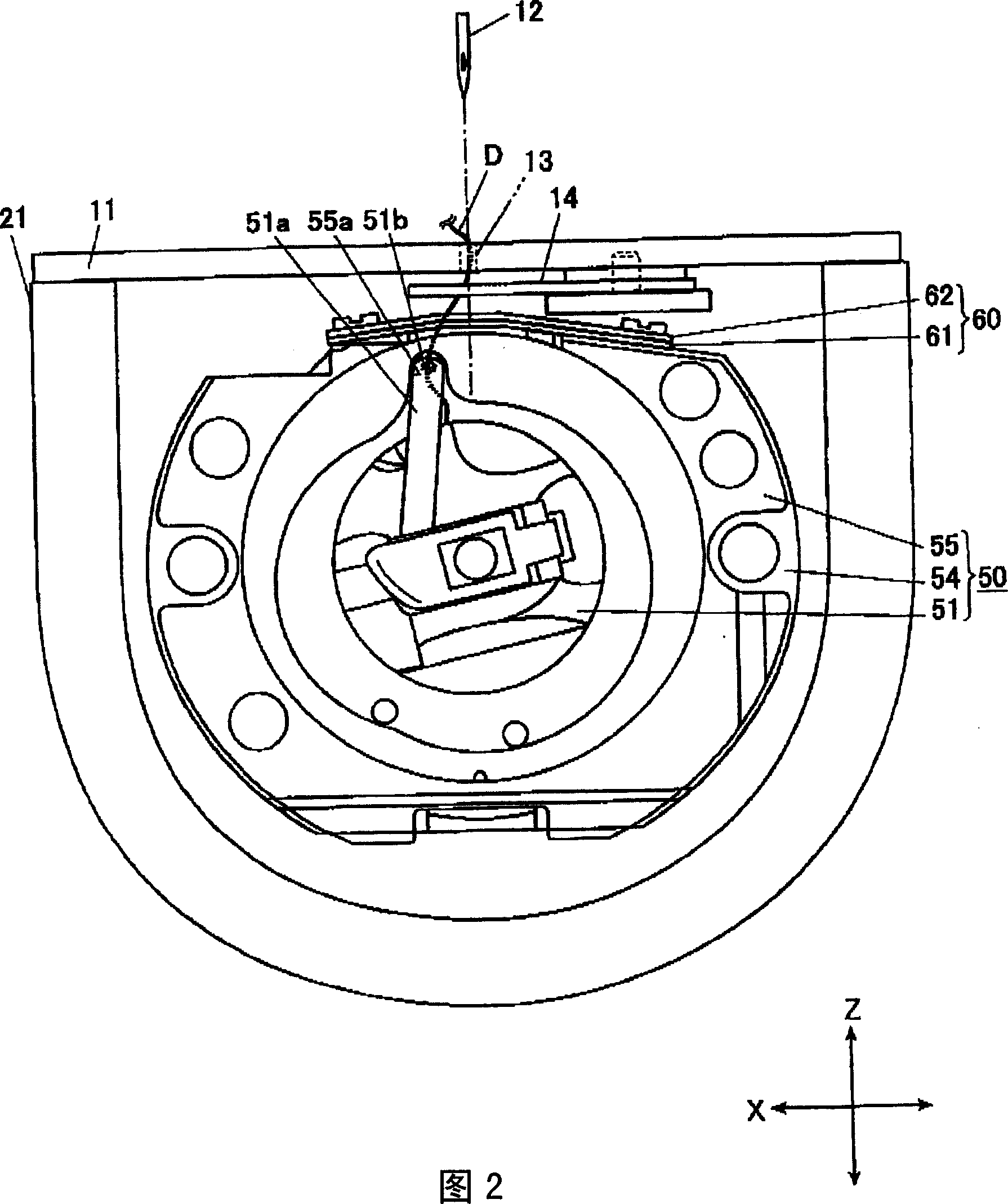

[0027] Based on Figure 1~ Figure 5 The rotary hook mechanism 50 which is an embodiment of the present invention will be described. FIG. 1 is a perspective view showing main parts of a sewing machine 10 equipped with a rotary hook mechanism 50 .

[0028] Hereinafter, let the direction parallel to the upper surface of the needle plate 11 described later and parallel to the hook shaft of the sewing machine 10 not shown be the Y-axis direction, and let the direction parallel to the upper surface of the needle plate 11 and be perpendicular to the Y-axis direction be As the X-axis direction, the direction perpendicular to the upper surface of the needle plate 11 is used as the Z-axis direction, and each part of the sewing machine will be described.

[0029] The sewing machine 10 has a frame 20 formed approximately in the shape of a "U" as a whole, and the frame 20 has: a bottom plate portion 21 located at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com