Monomer and method of manufacturing liquid crystal display panel using same

A monomer and liquid crystal layer technology, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems affecting the display quality of liquid crystal display panels, lattice defects, and different diffusion distances between reactive monomers and liquid crystal molecules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

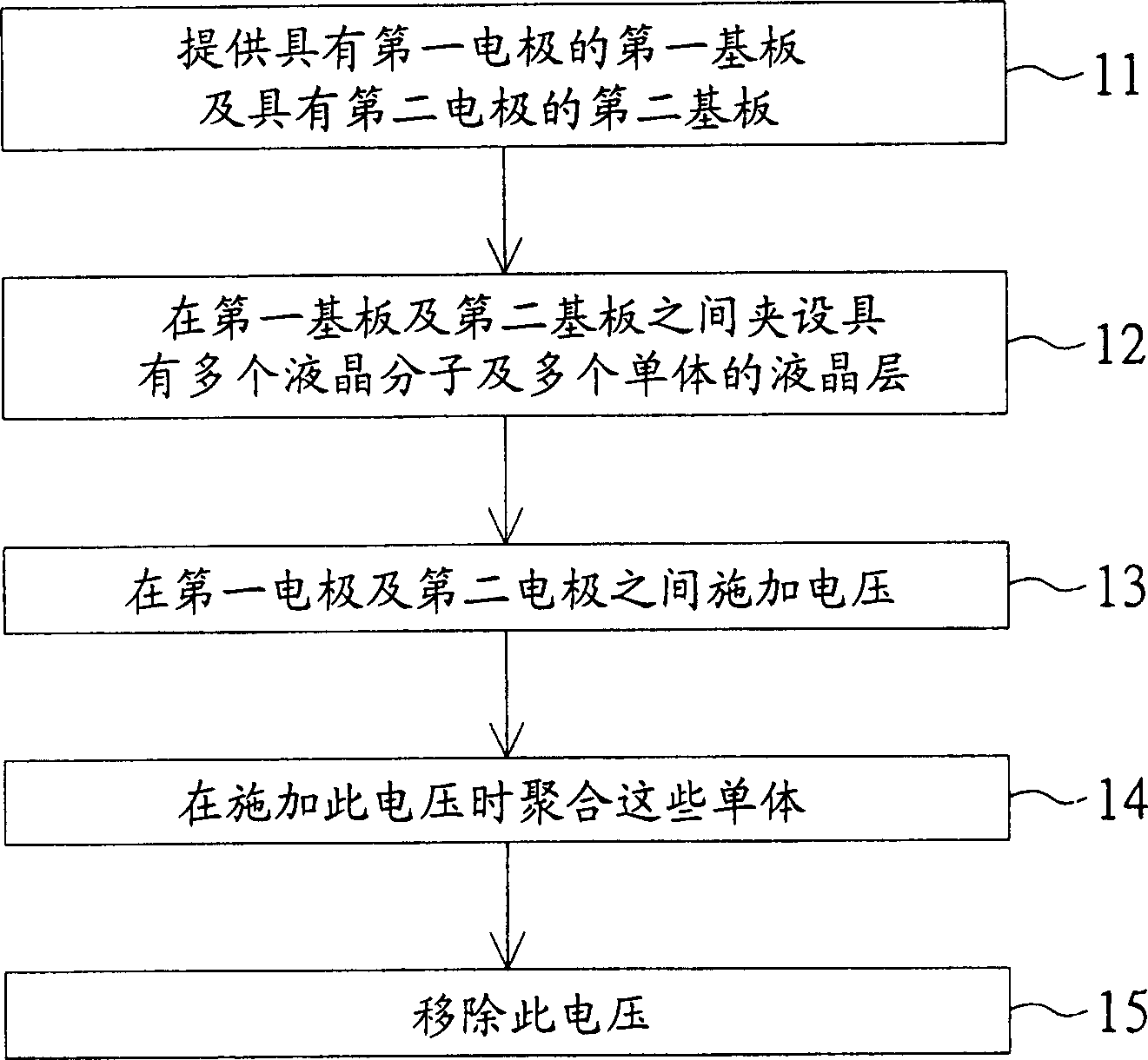

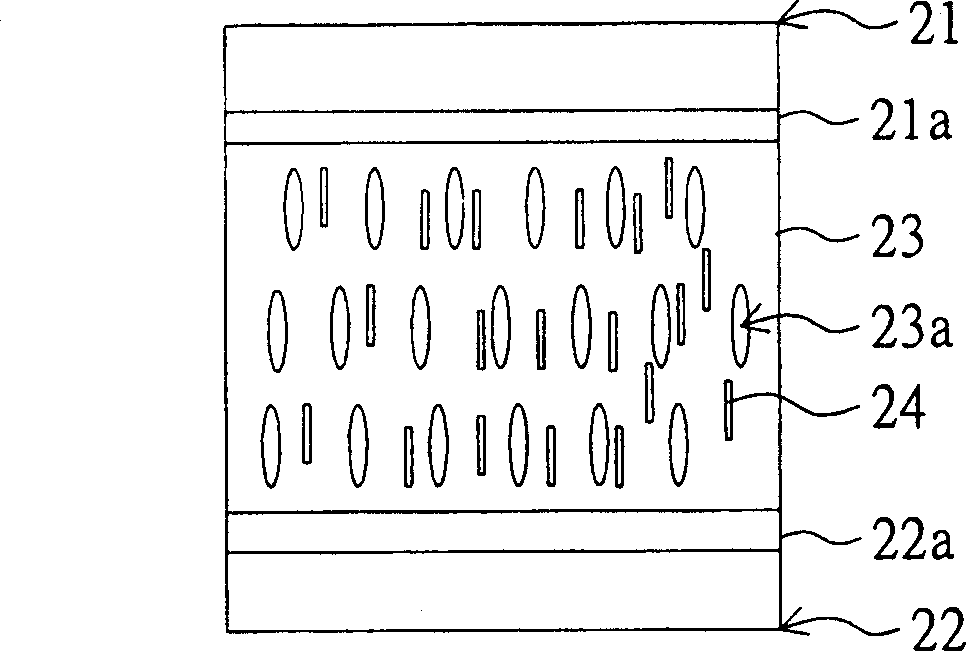

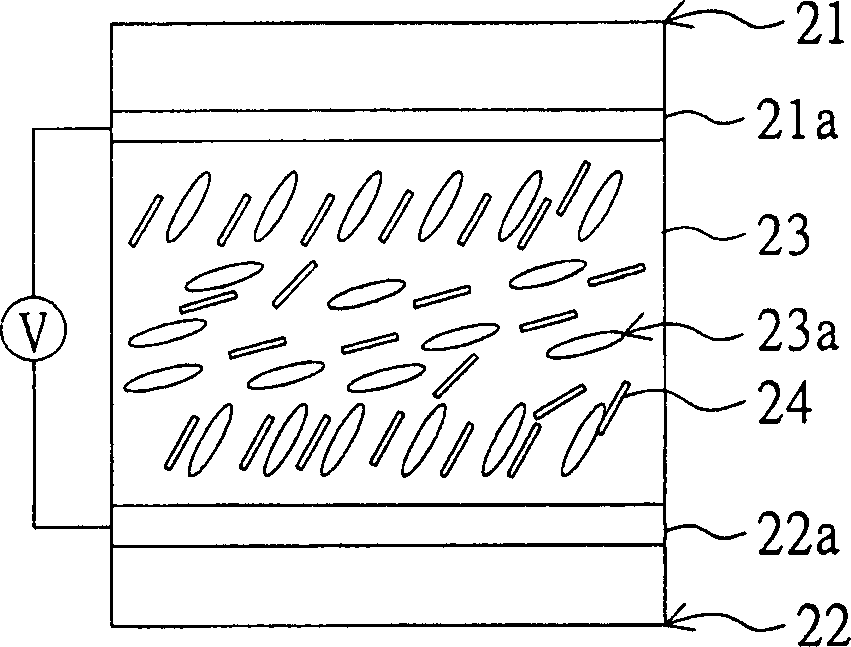

[0029] Please also refer to figure 1 and Figure 2A-2D , figure 1 is a flowchart showing a method of manufacturing a liquid crystal display panel according to a preferred embodiment of the present invention, Figure 2A-2D is a process sectional view showing a method of manufacturing a liquid crystal display panel according to a preferred embodiment of the present invention.

[0030] First, in step 11, as in Figure 2A As shown, a first substrate 21 and a second substrate 22 are provided, and the first substrate 21 and the second substrate 22 respectively have a first electrode 21 a and a second electrode 22 a. Then, enter step 12, and as Figure 2A As shown, the liquid crystal layer 23 is formed between the first substrate 21 and the second substrate 22, and the liquid crystal layer 23 is located between the first electrode 21a and the second electrode 22a. Wherein, the liquid crystal layer 23 has a plurality of liquid crystal molecules 23 a and a plurality of monomers 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com