New application of high fine collected ash from cement factory dust collector and cement containing high fine collected ash

A technology for collecting dust and cement plants, which is applied in the new application field of high-fine dust collection in cement plants, which can solve problems such as waste, and achieve the effects of increasing compactness, improving workability, and increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

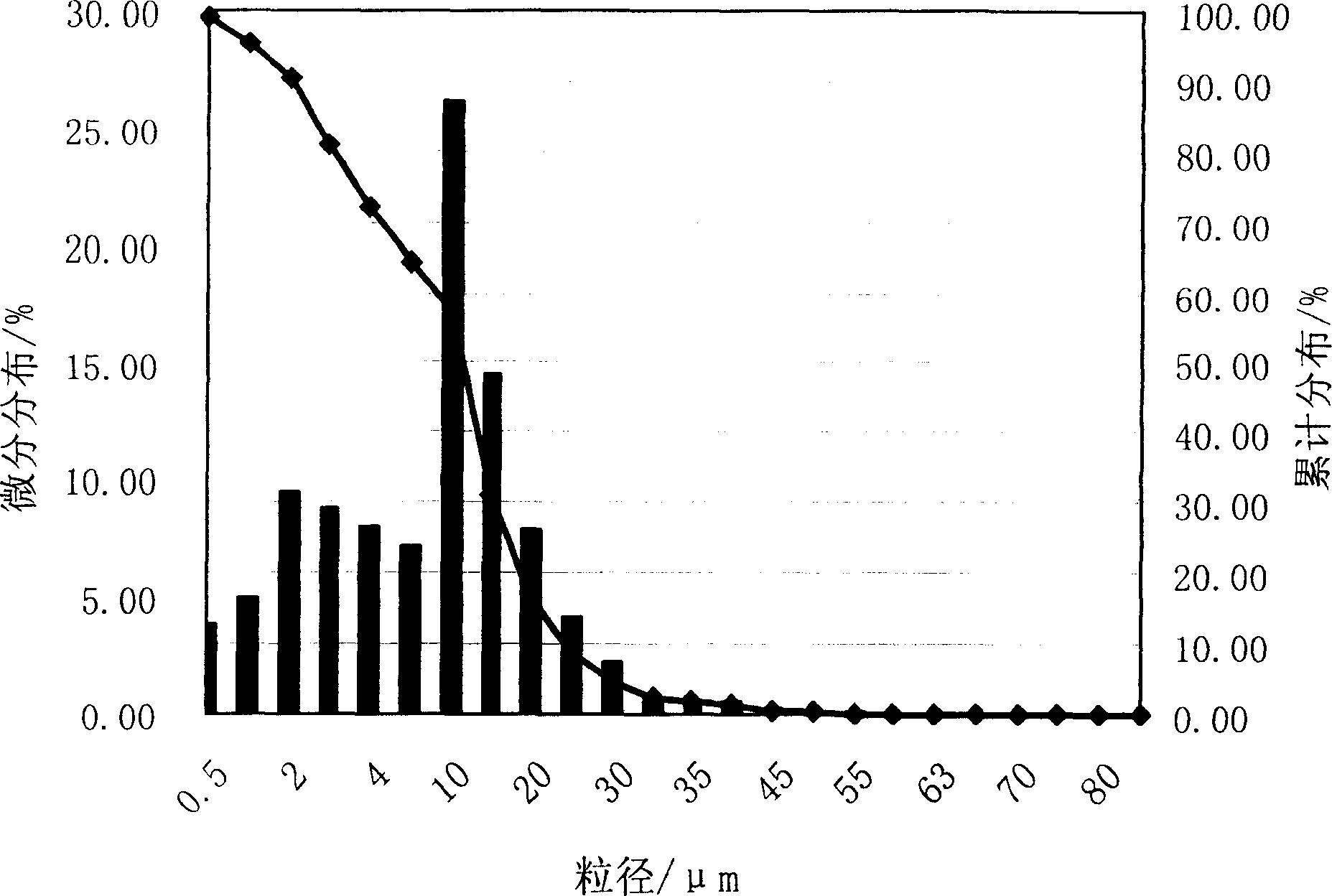

Image

Examples

Embodiment 1

[0029] Add high-fine ash as 4% (percentage by weight) directly into various finished cements (including general-purpose cement and special cement). The performance test results of various cements are shown in the table below.

[0030] Table 1

[0031]

[0032] Note: A space means no data

[0033] Table 2

[0034]

[0035] LL-1

[0036] Note: A space means no data

Embodiment 2

[0038] The Portland cement is mixed with 15% by weight of high-fine dust collection ash, and the Portland cement accounts for 85%. Among them, Portland cement (taking Portland cement as 100%) clinker is 95%, gypsum is 5%, and other common mixed materials are 0%.

[0039] Silicate

Embodiment 3

[0041] The composite Portland cement is mixed with 6% of high-fine dust collection ash by weight, and the composite Portland cement accounts for 94%. Among them, in the composite Portland cement (calculated as 100% of the composite Portland cement) clinker is 64%, gypsum is 5%, and other common mixed materials are 31%.

[0042] Complex silicic acid

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com