Evaluating system for dust removing technology of coal burning power generation plant

A coal-fired power plant, electric dust removal technology, applied in the direction of information technology support system, electrical digital data processing, special data processing applications, etc., can solve problems that have not been discussed, achieve short design cycle, convenient operation, overcome experience and random effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

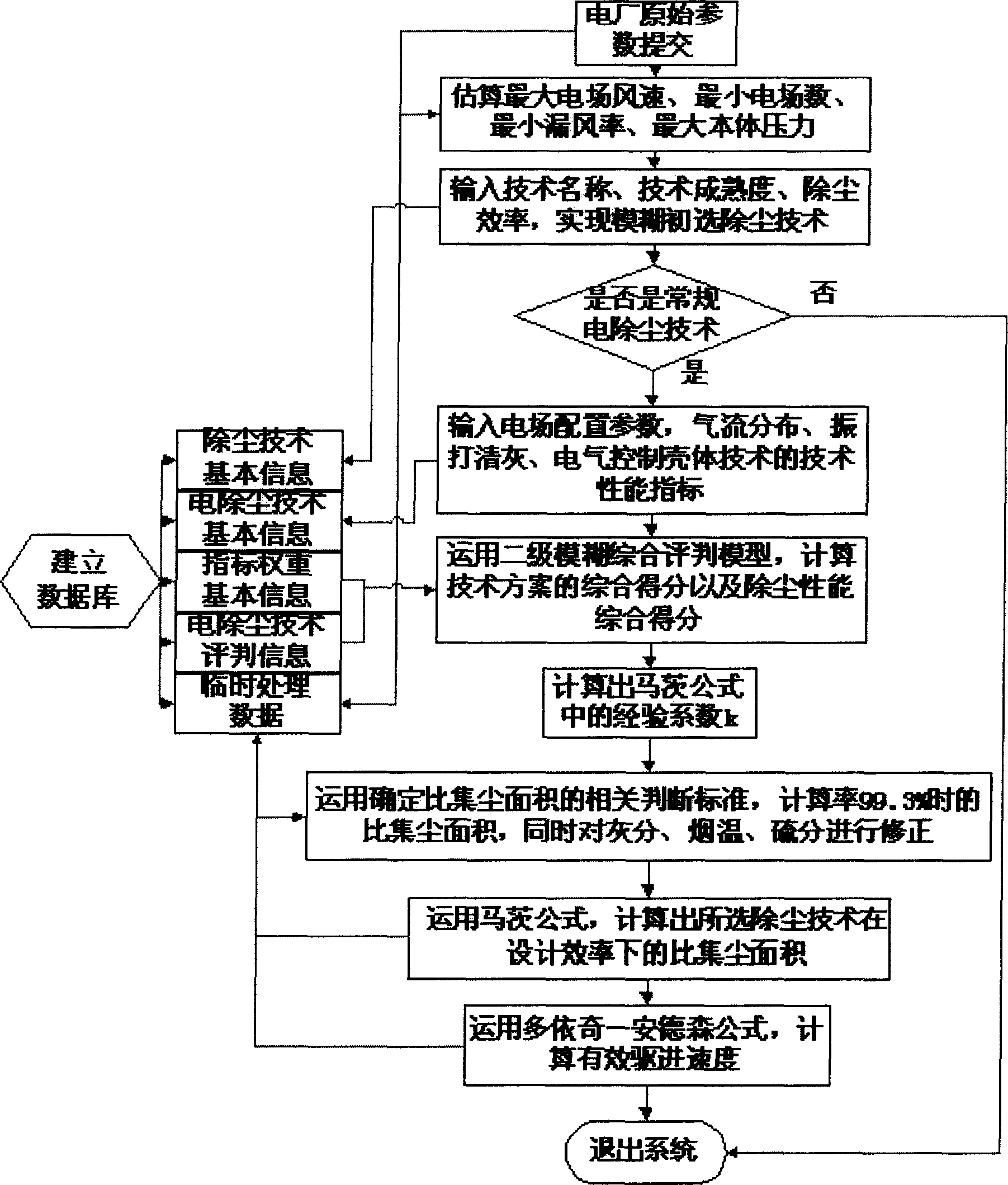

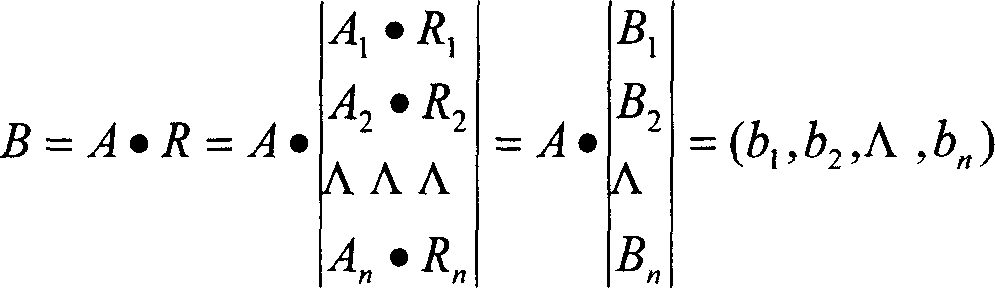

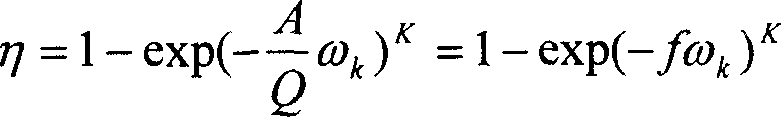

Method used

Image

Examples

Embodiment

[0048]1 For the expansion of the sixth phase of a power plant, this system is used to select and evaluate the transformation plan of the supporting electrostatic precipitator to determine the feasibility of this technical plan.

[0049] (1) Utilize established databases, including:

[0050] Basic information of dedusting technology: such as conventional ESP technology, bag dedusting technology, E-bag composite dedusting technology, moving electrode ESP technology, etc., related information such as technical name, dust removal efficiency range, technology maturity and technical description, etc., for users to inquire , add and delete; basic information on electrostatic precipitator technology: mainly includes plate line configuration experimental data and airflow distribution numerical simulation test data, provides experimental data of common plate line configuration methods, V-I characteristic curve and plate surface current density distribution curve, and Airflow distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com