An intervertebral prosthesis

An intervertebral prosthetic and intervertebral technology, applied in the field of intervertebral prosthesis, can solve problems such as obstructing chisel or bone knife passage, and difficulty in detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

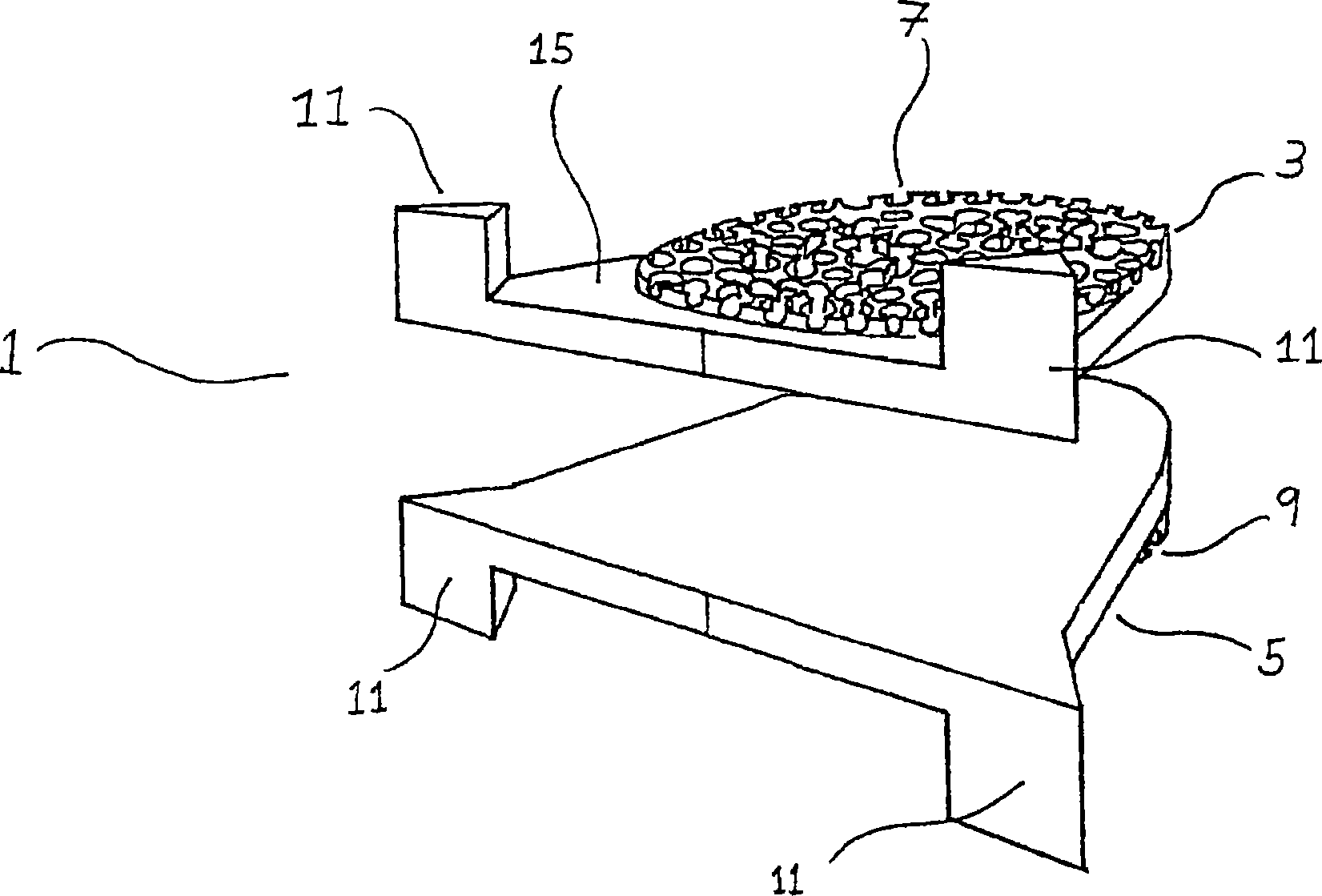

[0068] Example 1 - Prosthesis

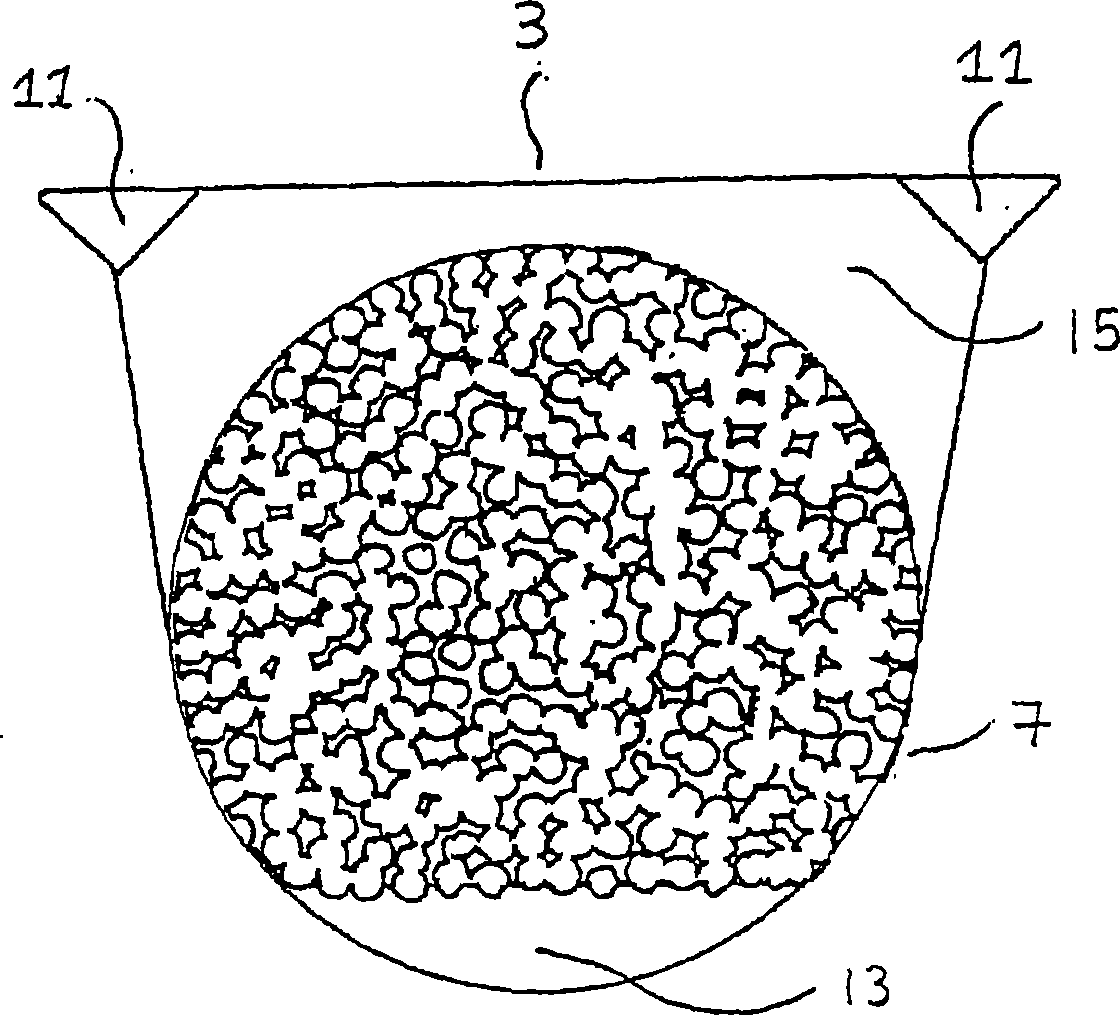

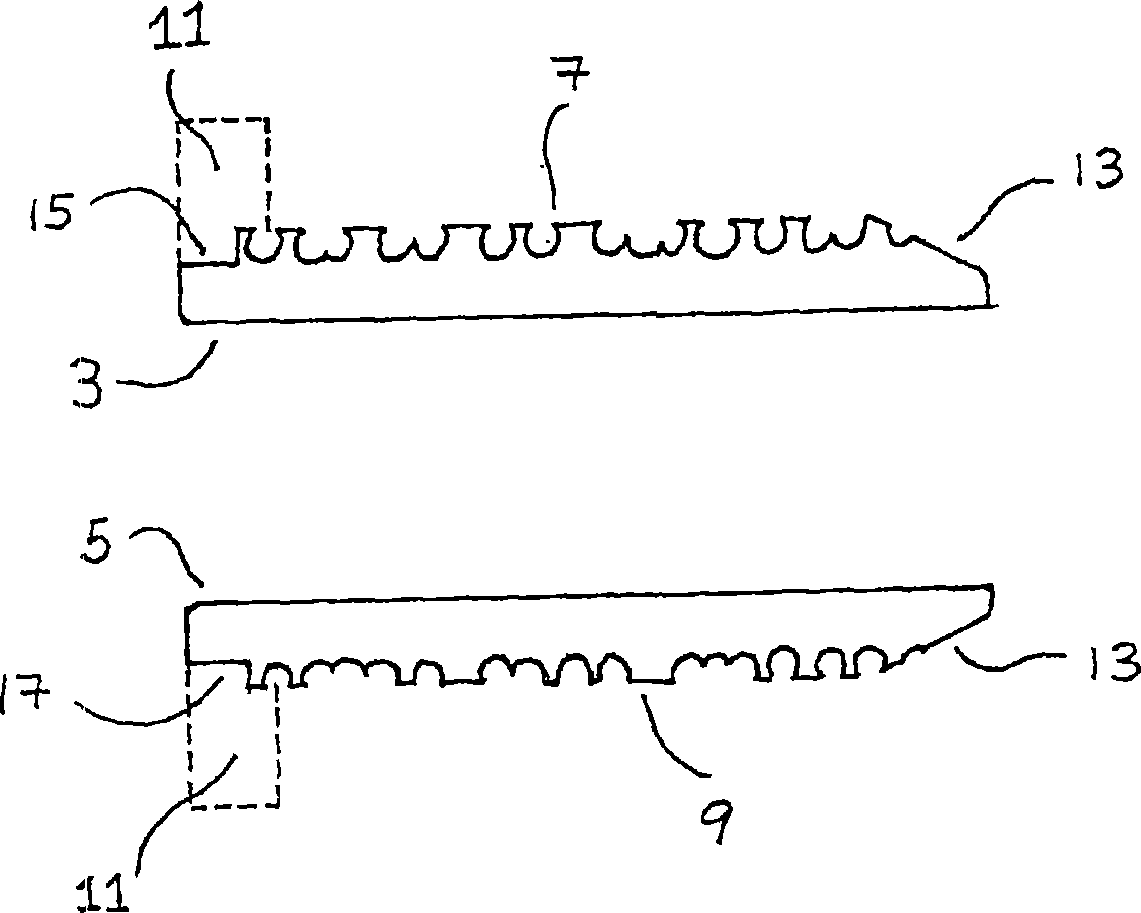

[0069] Intervertebral prosthesis 1 such as figure 1 As shown, it has a first plate 3 and a second plate 5 . The intervertebral prosthesis is made of titanium carbide. Plates 3 and 5 are articulated together by any suitable mechanism. In the prosthesis shown in Figure 4b, the ball and socket joint described in US Patent No. 6,113,637 is shown. Each plate 3 and 5 has a bone engaging surface 7 and 9 with a large textured surface. Large textured surface by e.g. Chem Tex or Tecotex It is formed by chemical texturing method and includes a surface with pores, wherein the radius of the pores is generally greater than 0.4mm. The large textured surface is roughly flat. The depths of the pores formed on the macro-textured surface are about the same, making the macro-textured surface substantially uniform.

[0070] Each plate 3 and 5 has a chamfered trailing edge 13, as figure 2 and 3 shown. The posterior edge 13 is the leading edge of the p...

Embodiment 2

[0074] Example 2 - Use of the prosthesis

[0075] The anesthetized patient is placed supine on the operating table with the neck held in a neutral position and neck traction applied using, for example, a Holter traction system. The anterior cervical spine is exposed at appropriate nodes by a transverse cervical incision.

[0076] Excision and decompression of the neck are performed in a conventional manner, and then the vertebral endplates are parallelized using a burrstone. Now release the neck traction.

[0077] Next, determine the disc gap depth and height using the abrasive test equipment of choice. A suitable grinding test apparatus 19 is shown in FIG. 5 . The grinding test device has approximately the same dimensions as the prosthesis 1 to be fitted, except that it is below the combined height of the large grains of the first plate 7 and the second plate 9 of the prosthesis, and that it is at a height corresponding to the convexity on the prosthesis 1. The position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com