Large power LED extended light soure

A technology of expanding light source and high power, applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems of poor uniformity of luminous intensity, large loss of light energy, difficult secondary optical design, etc. Simple and convenient for high-volume continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

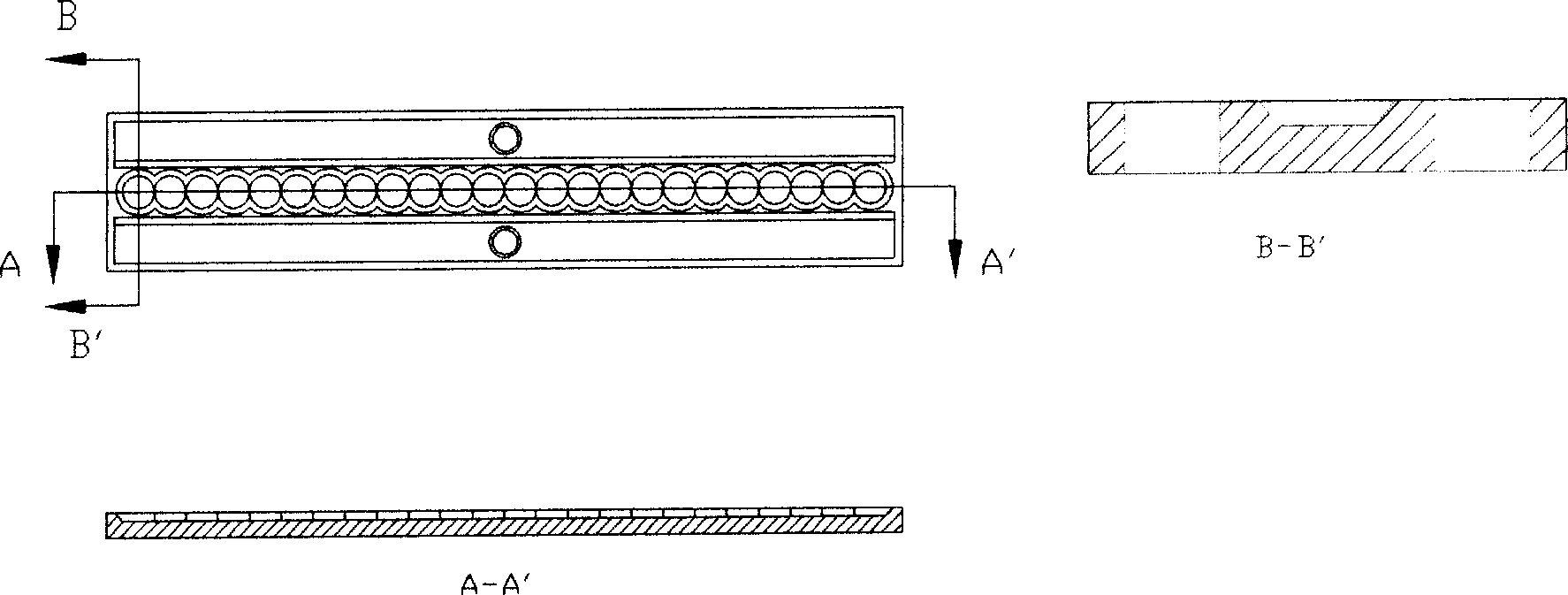

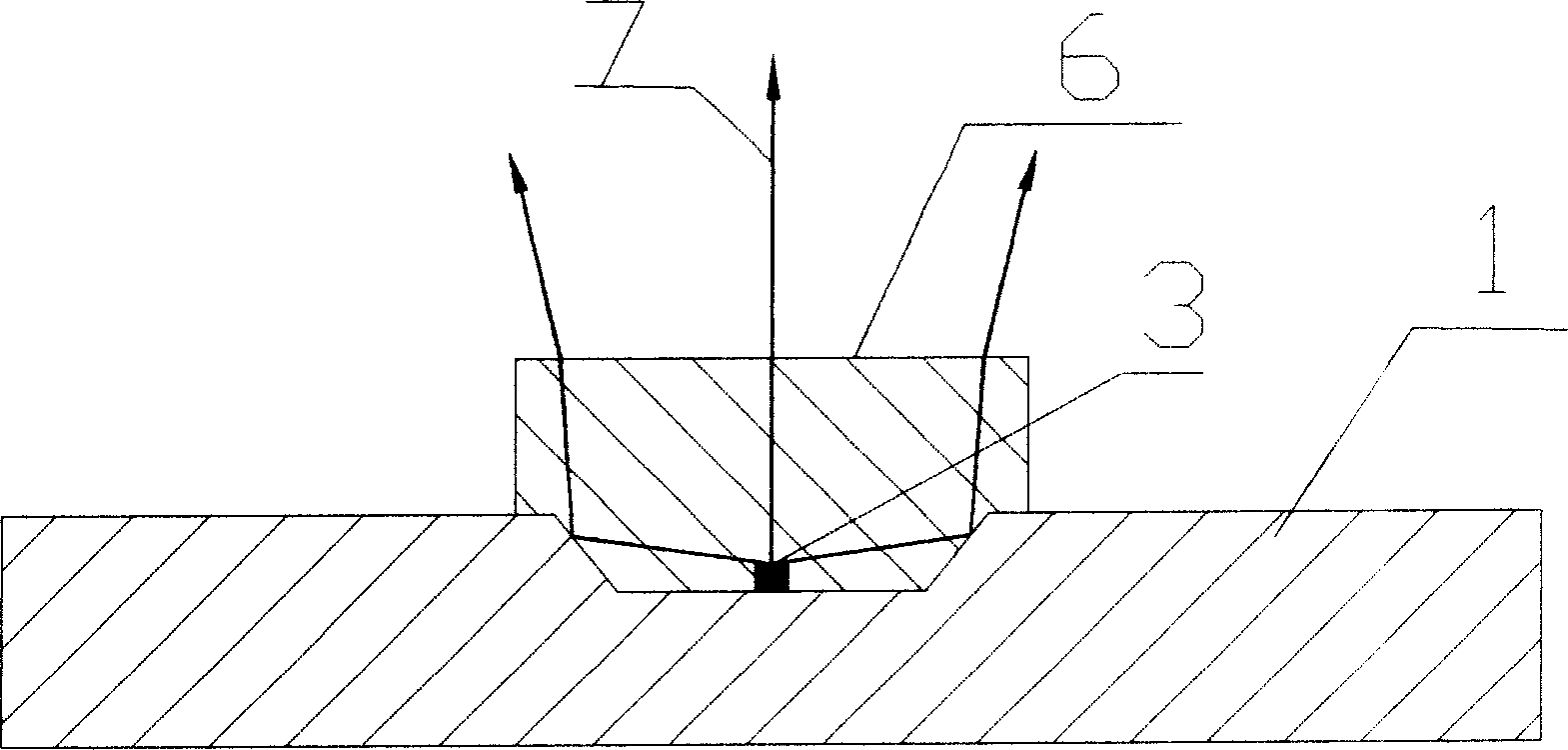

[0020] Embodiment 1, with reference to figure 1 , the strip-shaped metal substrate 1 has a crystal-bonding area 2 and a bonding wire area 4 . Wherein the bonding wire area 4 is a plating layer processed after an insulation treatment on the metal substrate 1 , and has higher insulation requirements with the metal substrate 1 . The crystal-bonding area 2 is a groove with a specular reflection layer after prescribed processing. exist figure 2 In the above, since the bottom surface of the groove is a tangential circle, the bottom surface of the groove is connected to a line when viewed from the center line, and the bottom surface is already a continuous plane with a linear order of magnitude more than a centimeter relative to the micron-scale chip, and then the chip 3. Die bonding is in the center of the groove, and the positive and negative electrodes of the chip are led to the bonding wire area 4 with bonding wires. Finally, from a microscopic point of view, the chip 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com