Rotating connection apparatus for borehole pump pouring concrete rotary guniting enlarging footing piling

A technology of concrete rotary spraying grouting and rotary joints, which is applied in the pile-forming device of pressure grouting and in the field of pressure grouting for construction, and can solve problems such as increasing production costs, grout leakage at the grout inlet, and affecting grouting speed and quality. It achieves the effects of easy disassembly, improved single-column bearing capacity, and good work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

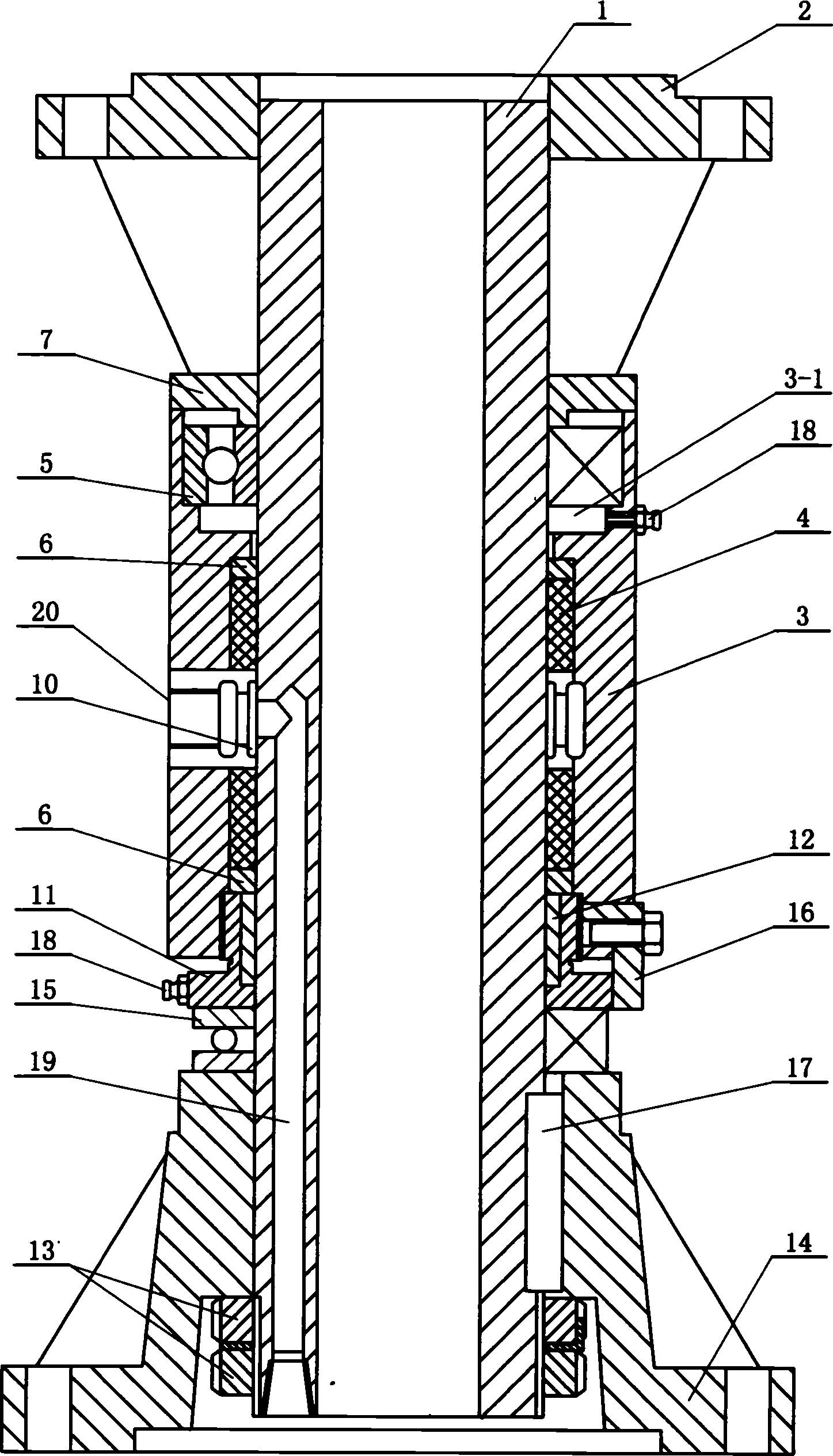

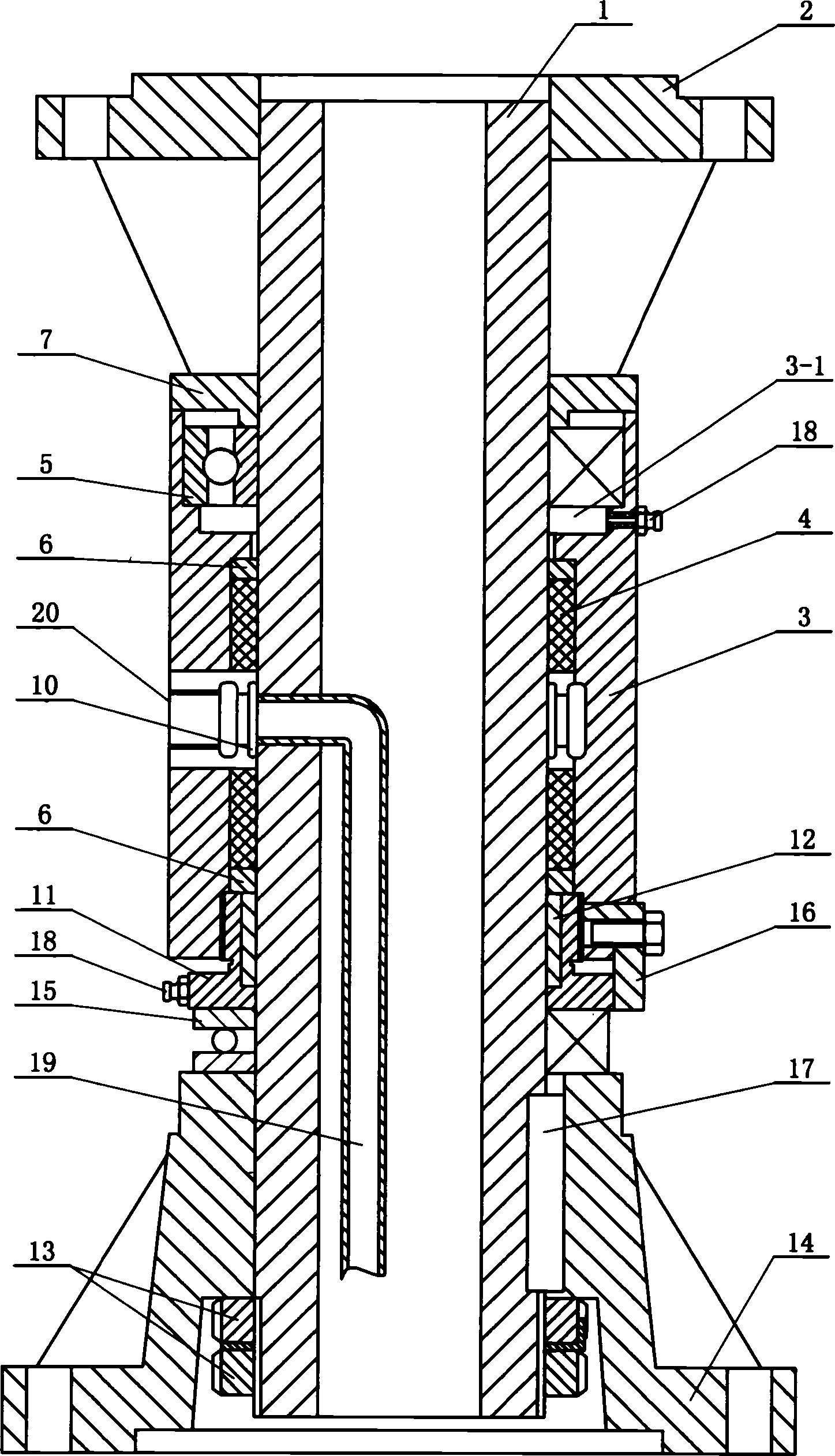

[0006] Specific implementation mode one: combine figure 1 , figure 2 Describe this embodiment, this embodiment consists of a main body pipe 1, an upper connecting plate 2, an outer jacket 3, a sealing sleeve 4, a first bearing 5, a retaining ring 7, a flower sleeve 10, a lower connecting plate 14, a second bearing 15, a slurry Pipe 19 and slurry inlet hole 20; the upper end of the main pipe 1 is fixed in the upper connection plate 2, the lower end of the main pipe 1 is fixed in the lower connection plate 14, the main pipe 1 is equipped with a jacket 3, the main pipe 1 and the jacket 3 Sealing sleeve 4 is housed between, outer jacket 3 and main body pipe 1 are provided with grouting hole 20 along the radially corresponding position, and flower cover 10 is housed on the main body pipe 1 in the grouting hole 20, the inside end of grouting hole 20 and The upper end of the slurry delivery pipe 19 is connected, the main body pipe 1 between the first bearing 5 and the upper connect...

specific Embodiment approach 2

[0007] Specific implementation mode two: combination figure 1 , figure 2 Describe this embodiment, the difference between this embodiment and specific embodiment one is: this embodiment also adds lubricating device 18; on the side wall. The lubricating device 18 is added to lubricate the first bearing 5 and the second bearing 15 respectively, ensuring that the first bearing 5 and the second bearing 15 work in a lubricated state, and prolonging the use of the first bearing 5 and the second bearing 15 life.

specific Embodiment approach 3

[0008] Specific implementation mode three: combination figure 1 , figure 2 Describe this embodiment, the difference between this embodiment and the specific embodiment one is: this embodiment also adds a pressure ring 11, a copper sleeve 12, and a retaining key 16; A copper sleeve 12 is installed between the ring 11 and the main pipe 1 , and a retaining key 16 is fixed on the outer end of the pressure ring 11 . A copper sleeve 12 is installed between the pressure ring 11 and the main pipe 1, which can not only support the sealing sleeve 4, but also reduce the friction between the jacket 3 and the main pipe 1, so that the whole device does not generate heat when it is working. Resistant to wear, thereby increasing the service life of the entire unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com