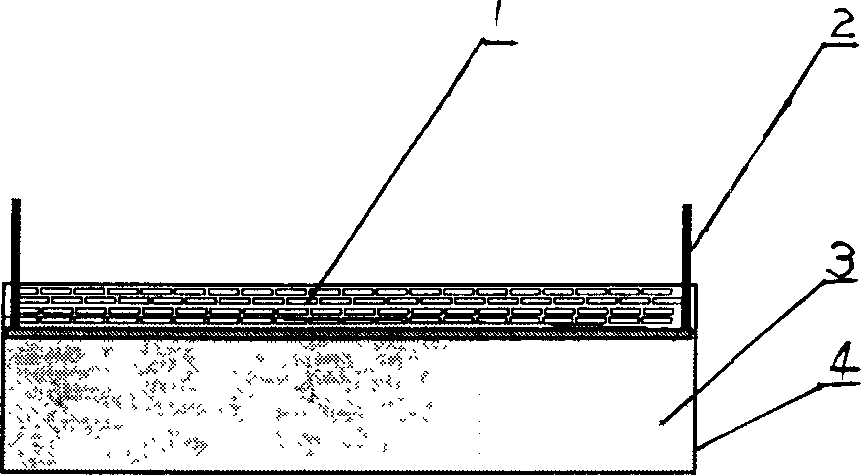

Method for producing float laminated blank assembly of bamboo strand lamination

A manufacturing method and a technology for forming blanks, which are applied in the manufacture of veneer chips, manufacturing tools, pretreatment of molding materials, etc., can solve the problems of poor uniformity, high cost, unsatisfactory labor-intensity, etc., so as to improve the quality of blanks and reduce the Cost, effect of improving utilization and bamboo performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] (1) Collection of bamboo

[0042] The collection of bamboo needs to have a clear record of bamboo species, collection location, collection time, collection quantity, collection person, bamboo age, diameter at breast height, length, and slightly diameter;

[0043] bamboo name

[0044] Bust diameter

[0045] Bending: Bamboo shall not have local bending, such as the dead bend at the root of bamboo. Overall bending is less than 1%.

[0046] defect name

[0047] (2) Visual classification of bamboo

[0048] Classify the diameter grade, length, tip diameter, bending degree and defects of bamboo;

[0049] The geometric shape of bamboo is a hollow bamboo stalk divided by bamboo nodes. The main geometric dimensions are: the length of the bamboo stalk, the diameter at breast height, the number of bamboo nodes, the distance between bamboo nodes, the long diameter of the large and small ends of the bamboo stalk; the short diameter and the length of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com