Compensation coil device for high temperature superconductive magnet test

A technology of high-temperature superconducting and compensation coils, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve problems such as inconvenient testing, achieve accurate and convenient testing, and solve the effects of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

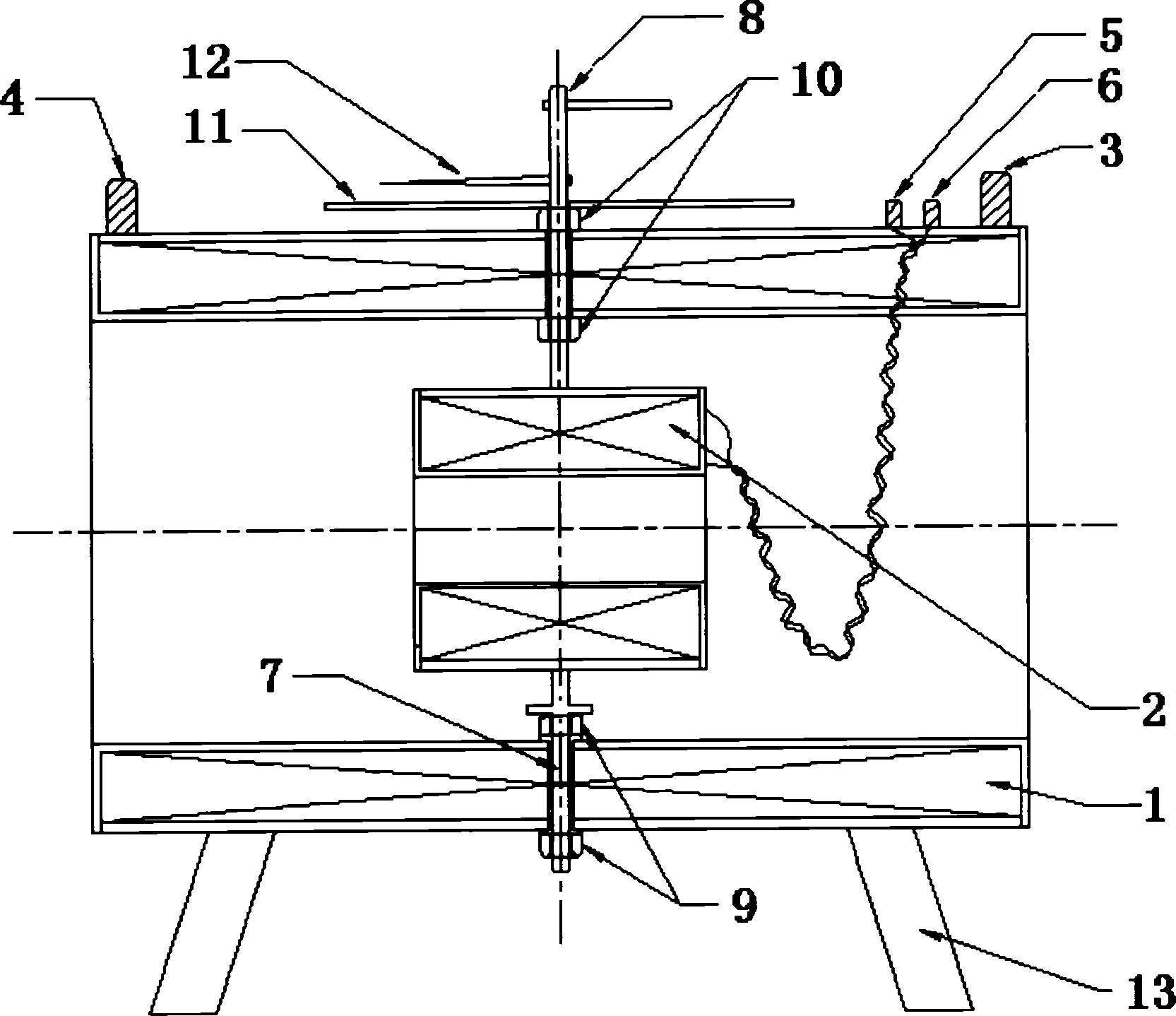

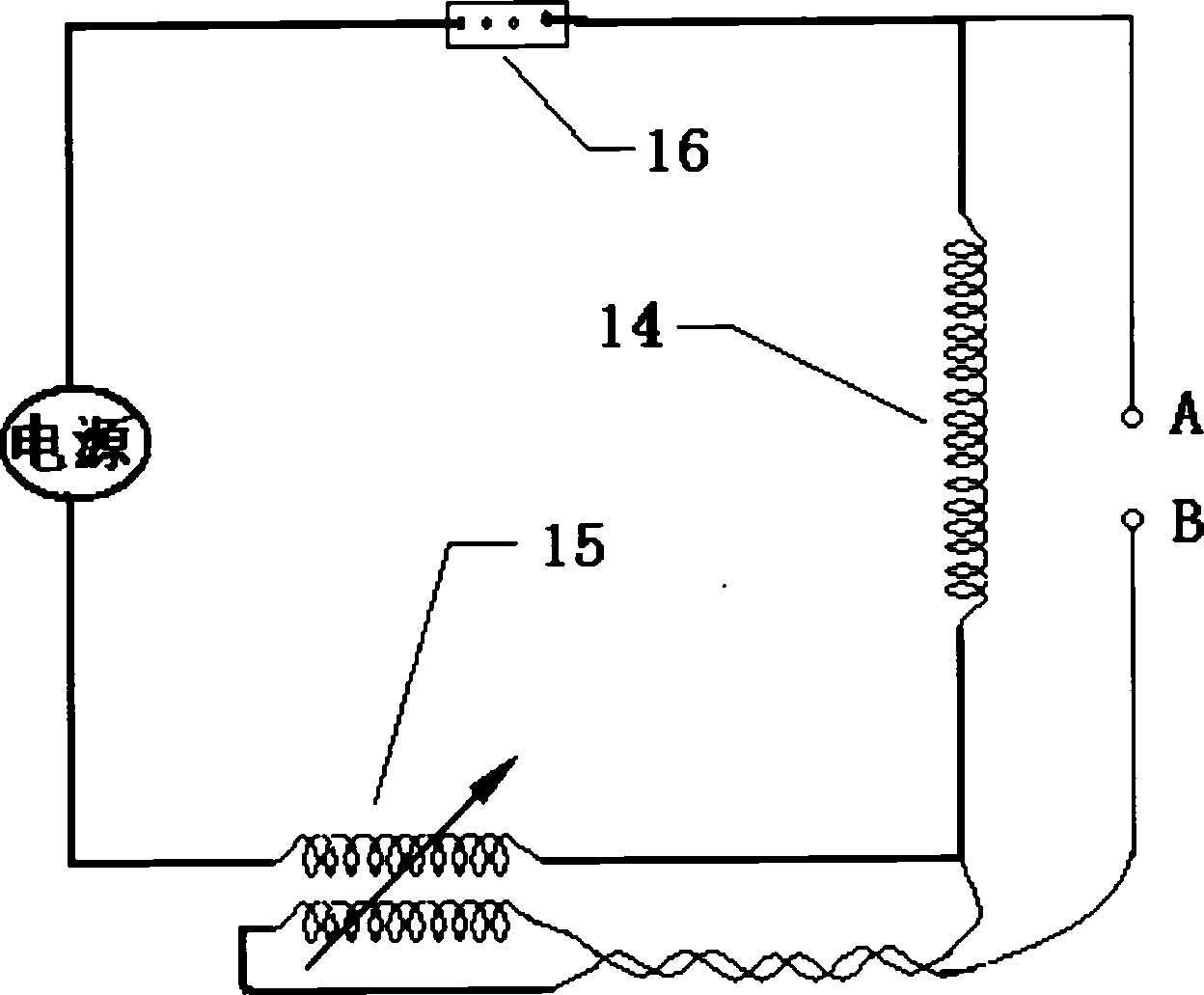

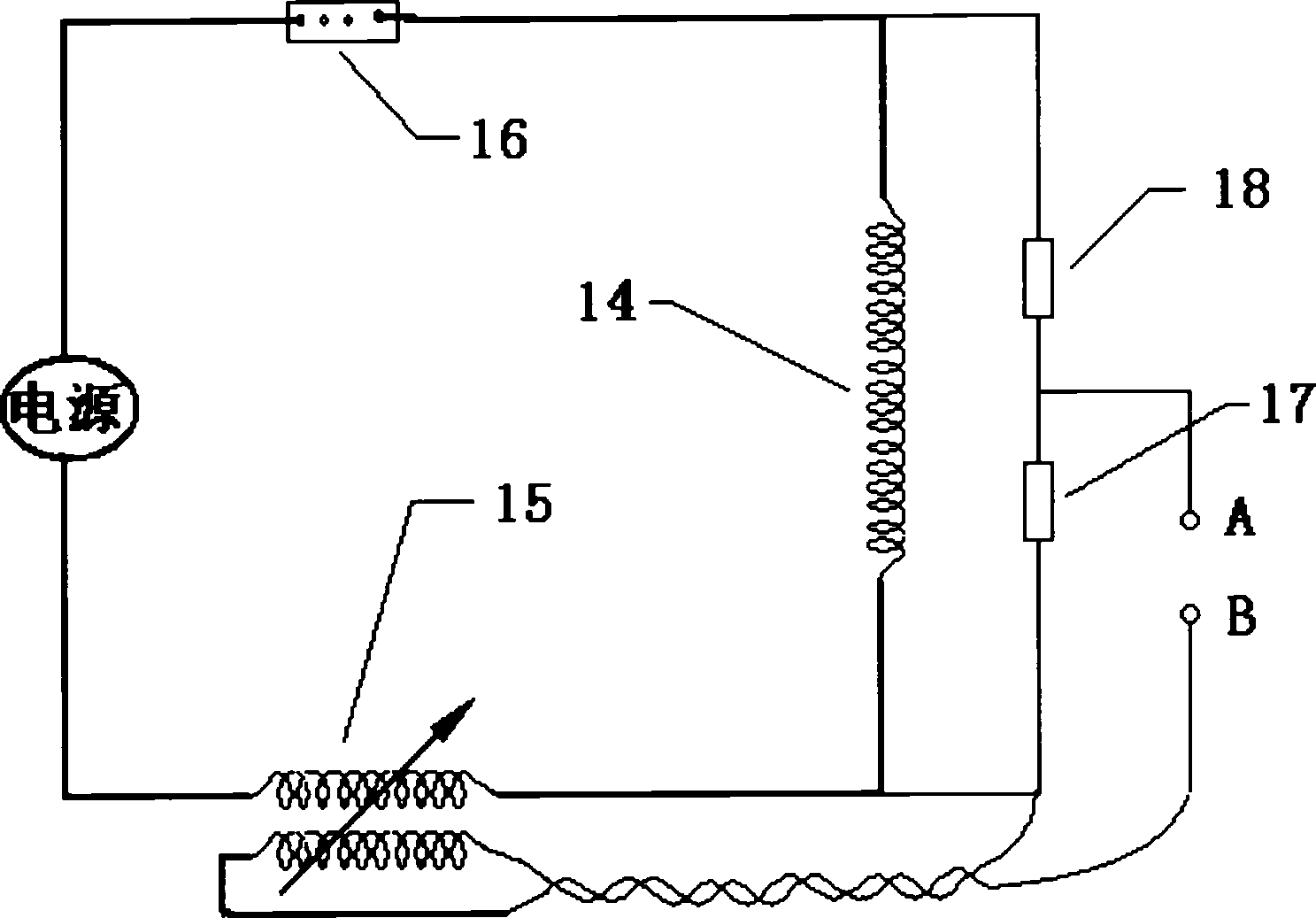

[0021] like figure 1 As shown, the present invention mainly consists of outer coil 1, inner coil 2 and accessory devices: outer coil terminal 3,4, inner coil terminal 5,6, lower fixed rod 7, upper fixed rod 8, bearing 9,10, scale Plate 11, pointer 12, and bracket 13 constitute. The outer coil 1 is the main coil, wound with a thicker wire, and the number of turns is less inductance L 1 Small, the flow capacity is larger than the critical current of the measured magnet 14. The inner coil 2 is the auxiliary coil, the wire is wound with copper enameled wire of 0.05-1mm, and the number of turns is more than the inductance L 2 big. The central hole of the main coil 1 is relatively large, and the secondary coil 2 is positioned in the central hole of the main coil 1 through the lower fixed rod 7 and the upper fixed rod 8, and the upper fixed rod 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com