Gear stepping type stepless speed change device

A step-by-step technology for step-by-step transmission, which is applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problems of difficult and large-displacement automobile applications, short life, large wear, etc., and achieve cost reduction Low, easy to control, wide range of shifting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

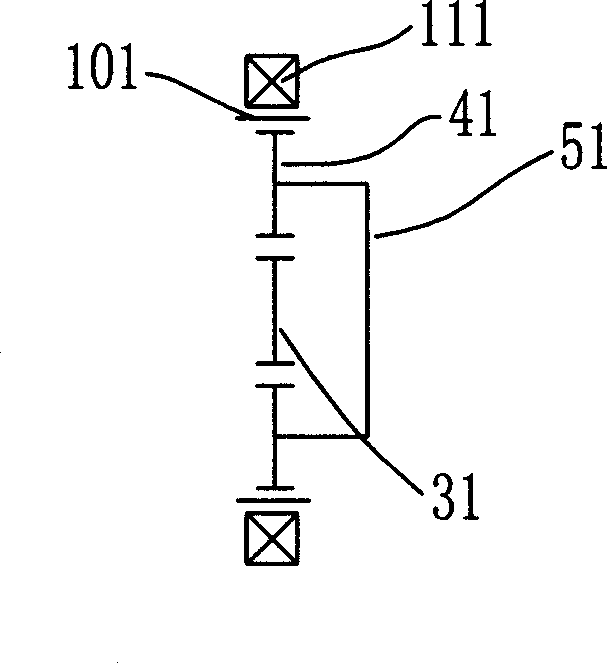

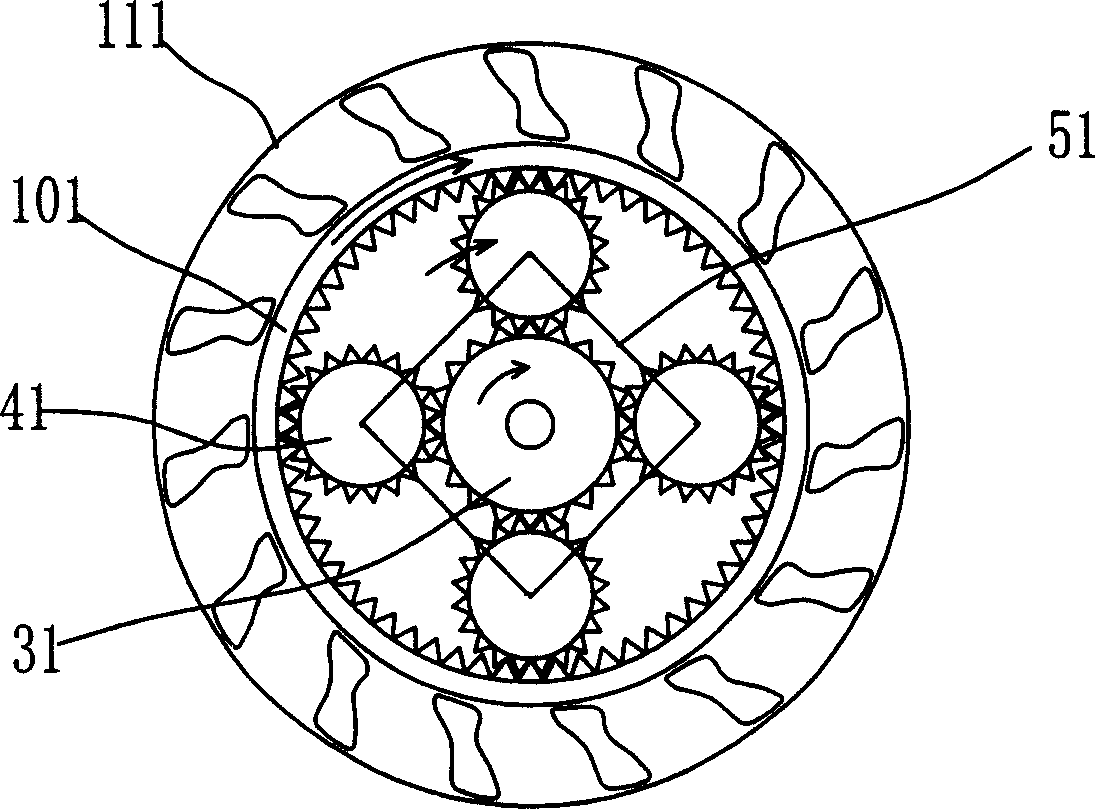

[0014] Embodiment one: as attached Figure 4 As shown, the device mainly includes a support frame 11, and a planetary gear train is installed in the support frame 11. The gear train includes: a driving sun gear 31, the driving sun gear 31 is fixedly connected to the input shaft 21, and there are three to 6 output planetary gears 41, the output planetary gears 41 are installed on the planetary gear frame 51, the planetary gear frame 51 is connected to the output shaft 61, and a speed regulating sun gear 71 is also arranged on the input shaft 21 in front of the driving sun gear 31, and the speed regulating The sun gear 71 is externally engaged with 3 to 6 speed-regulating planetary gears 91, the speed-regulating planetary gears 91 are installed on the planetary gear frame 81, the planetary gear frame 81 is fixed on the input shaft 21, the speed-regulating planetary gears 91, the output planetary gear 41 Engaging with the ring gear 101, there is a one-way bearing, that is, a one-...

Embodiment 2

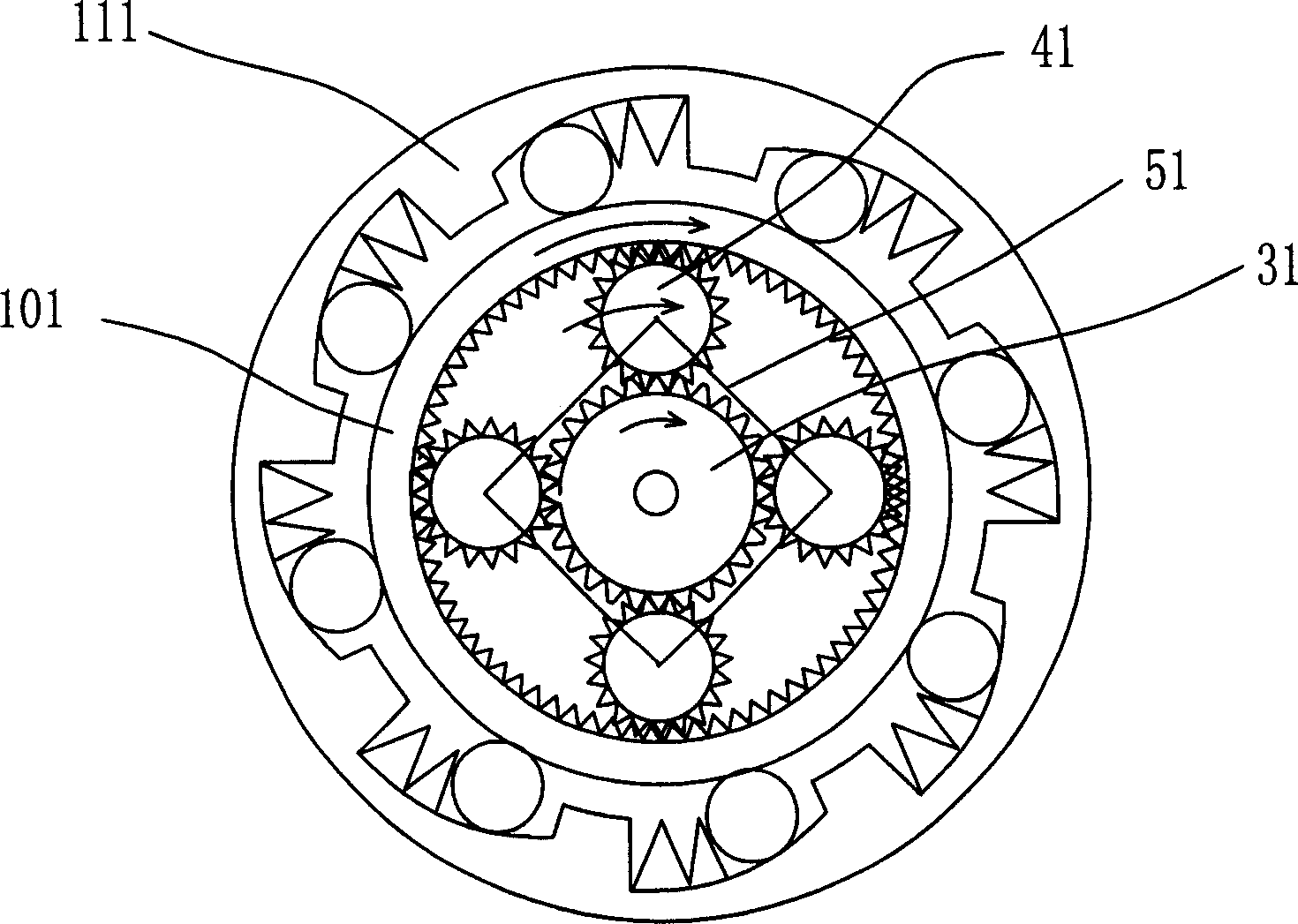

[0016] Embodiment two; Figure 5 As shown, the continuously variable transmission device mainly includes a support frame 11, and a planetary gear train is installed in the support frame 11. The gear train includes a driving sun gear 31. The driving sun gear 31 is fixedly connected to the input shaft 21 and engages along the periphery of the driving sun gear 31. There are 3 to 6 output planetary gears 41, the output planetary gears 41 are installed on the planetary gear frame 51, the planetary gear frame 51 is connected to the output shaft 61, and a speed regulating sun gear 71 is also arranged on the input shaft 21 in front of the driving sun gear 31 There are 3 to 6 speed-regulating planetary gears 92 externally meshed with the speed-regulating sun gear 71, each speed-regulating planetary gear 92 is installed on the planetary gear frame 51, and the revolution diameter of the speed-regulating planetary gear 92 is greater than the revolution diameter of the planetary gear 41, ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com