Double face printing apparatus and double face printing process

A double-sided printing and equipment technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of short drying time between colors, increased equipment manufacturing costs, printing speed limitations, etc., to achieve short travel paths and save Small footprint, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

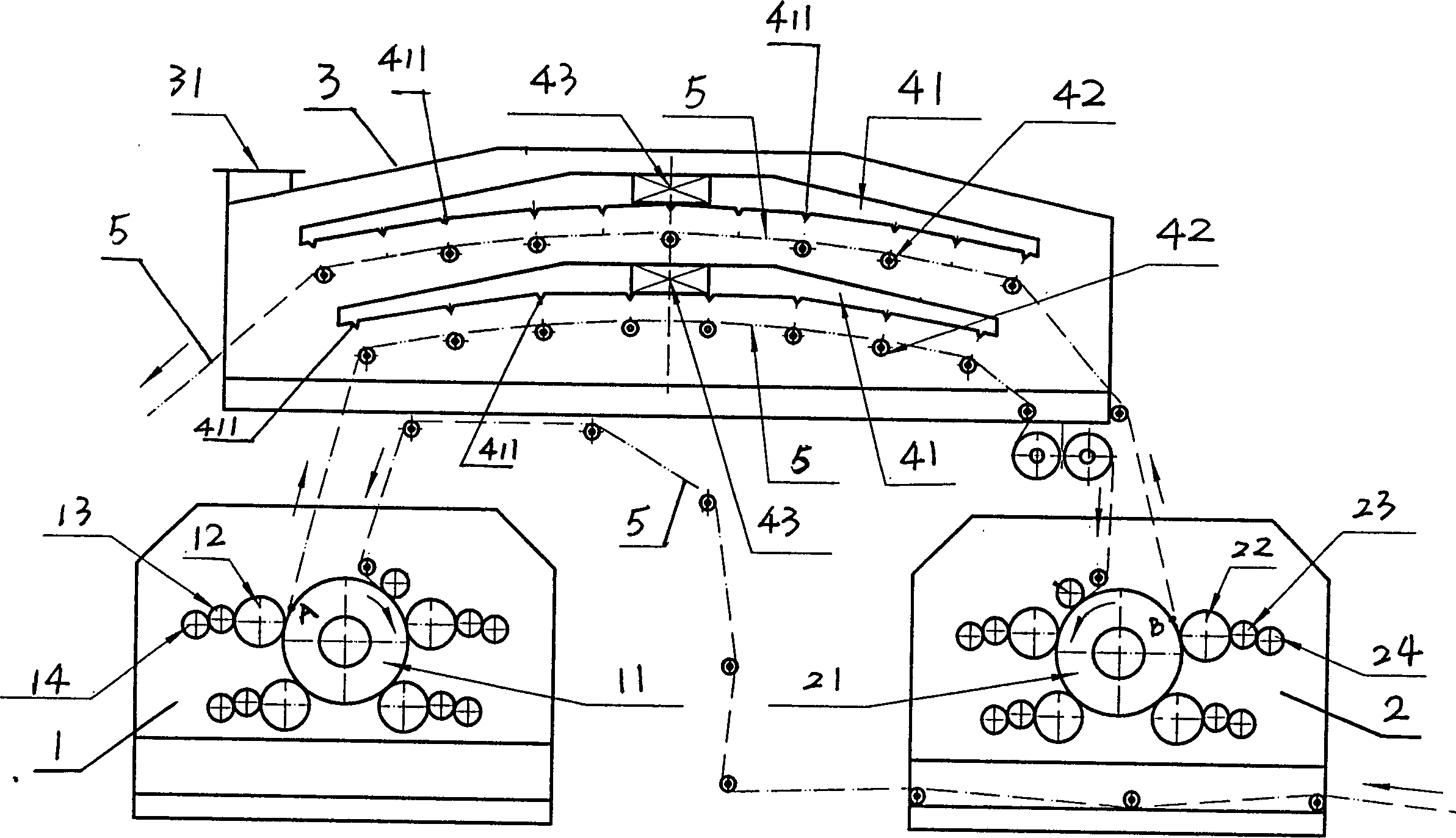

[0019] figure 1 As shown, the double-sided printing equipment of the present invention includes the first satellite printing unit 1, and the first satellite printing unit is equipped with a central pressure roller 11 and four plate rollers 12, and each plate roller 12 is correspondingly provided with a web. Textured roller 13 and inking rubber roller 14, the printing equipment is also provided with a second satellite printing unit 2, and the second satellite printing unit is also equipped with a central pressure roller 21 and four version rollers 22, each version roller 22 are all correspondingly provided with anilox roller 23 and inking rubber roller 24, and the installation directions of the rotating shafts of the center pressure rollers 11, 21 of the two printing units are parallel to each other; an oven 3 is arranged above the two satellite printing units. There are two drying tunnels running horizontally, the two drying tunnels are stacked up and down, each drying tunnel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com