Drum structure of dryer

A technology of dryers and drums, which is applied in household dryers, washing devices, textiles and papermaking, etc. It can solve the problems of difficult installation, easily damaged transmission belts, friction between conveyor belts and welding parts, etc., to improve drying efficiency and prolong service life , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

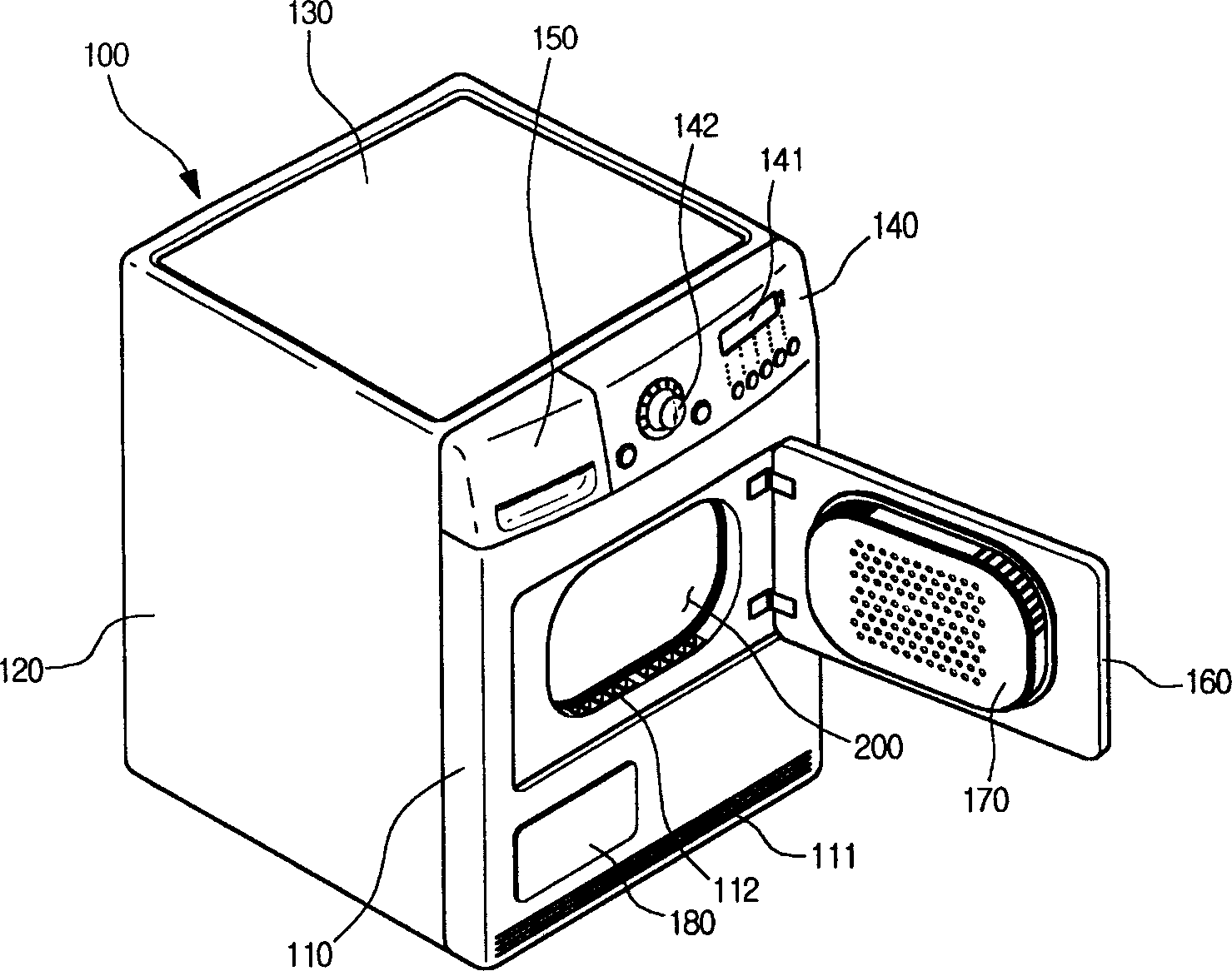

[0036] figure 1 It is a three-dimensional schematic diagram of the external structure of the present invention.

[0037] Such as figure 1 As shown, the dryer 100 provided by the present invention includes: a front cover 110, a side cover 120, and a top cover 130 that constitute the appearance; it is arranged above the front cover 110 and has a setting button 142 and a display screen for inputting the operating conditions of the dryer 100. 141 of the control panel 140 .

[0038] A condensed water box 150 for collecting condensed water generated during the drying process is inserted into a side of the control panel 140 close to the outside, and an opening is provided in the approximate center of the front cover 110 . There are also a door 160 for opening and closing the opening, and a door lint filter 170 pasted on the back of the door 160 to remove clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com