Method and device for controlling an installation for producing steel

A technology of production equipment and equipment, applied in the direction of general control system, adaptive control, control/regulation system, etc., can solve problems such as time delay, and achieve the effect of expanding tolerance range, less filling tasks, and long smelting sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

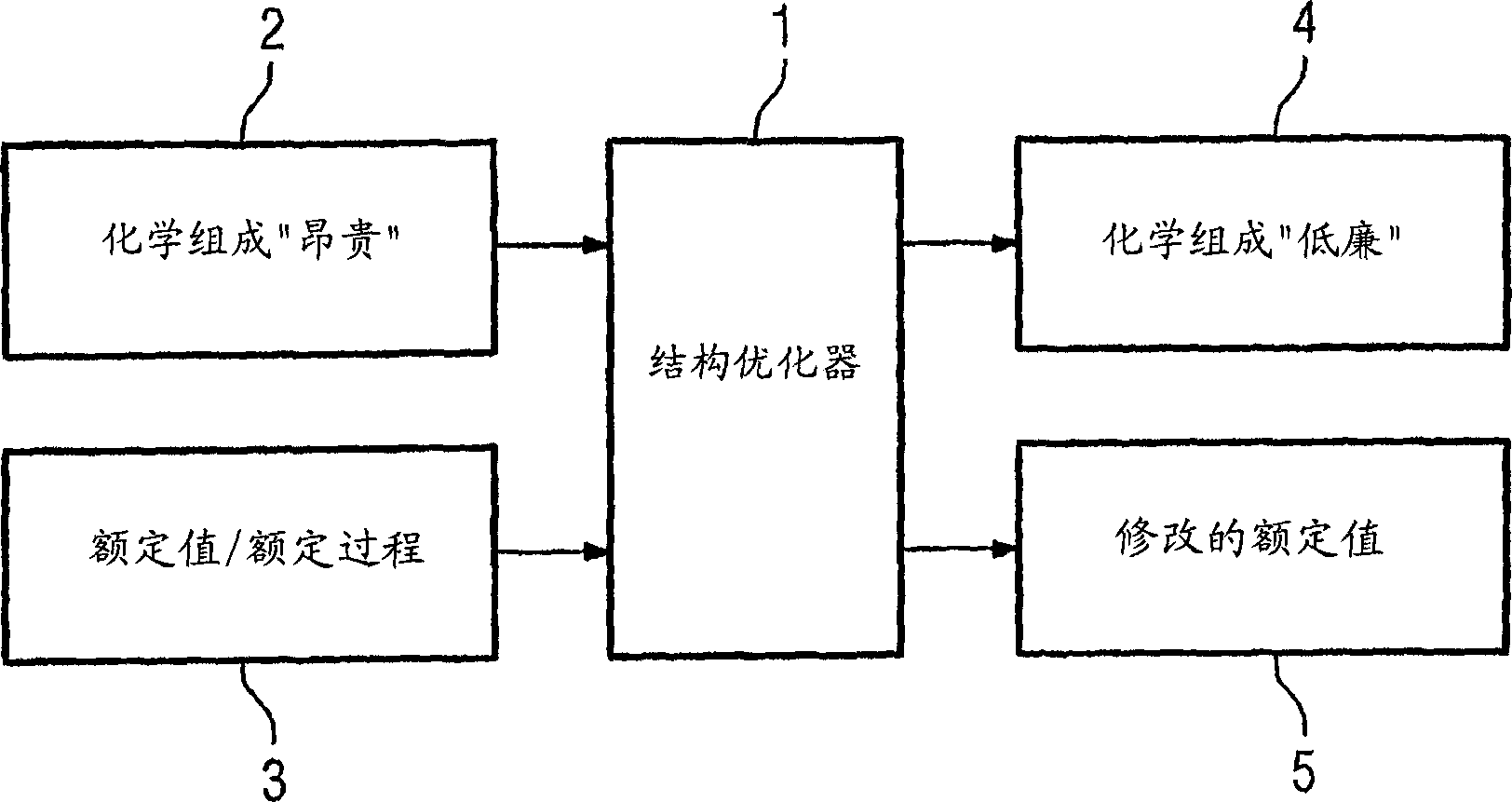

[0041] figure 1 Schematic diagram showing how the structure optimizer works in alloy cost optimization. The calculation program for optimizing the structure, designated below as structure optimizer 1 , obtains target values 2 for the chemical composition and target values 3 for the operating parameters of the target process. The nominal values 2, 3 together give the so-called steel profile, which is based on experience and contains all the information required for the production of the respective task. The material properties of the steel produced can be influenced by the operating parameters of the plant, including process temperature and pressure and, if appropriate, their time derivatives. A mathematical model is implemented in the structure optimizer 1 which simulates the material properties and determines the changes in the microstructure of the steel for each production step. The structure optimizer 1 can also work with the method of neural network. As a result,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com